I am by no means a skilled carpenter, but I do know how to use power tools, and I know a fair bit about building things out of wood. However, it extends to indoor structures likes desks and furniture. Nothing that could withstand the elements.

Most outdoor things you buy at the store are either made of metal and stone, or those that are built from wood are made like a deck, with spaced slats to allow dirt/water to pass through and not mingle.

I want to be able to build a bar like one of these:

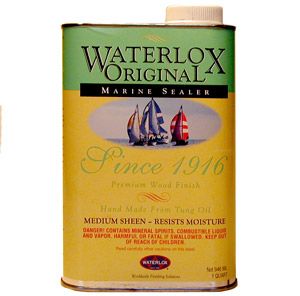

I have a square patch of cement in my backyard that used to have a hot tub on it, but is currently vacant (with power access!) I want to build an L shaped bar out of wood, and perhaps tile it (I am thinking of this as an alternative to lacquer for weather protection.) It would have area underneath for a fridge and storage. I don't know if I would put any doors on it or leave it open. I just do not want to have it built and set up with spaced slats. How would I go about building something that could handle the rain and not rot and warp like crazy?

Thanks tons!

Most outdoor things you buy at the store are either made of metal and stone, or those that are built from wood are made like a deck, with spaced slats to allow dirt/water to pass through and not mingle.

I want to be able to build a bar like one of these:

I have a square patch of cement in my backyard that used to have a hot tub on it, but is currently vacant (with power access!) I want to build an L shaped bar out of wood, and perhaps tile it (I am thinking of this as an alternative to lacquer for weather protection.) It would have area underneath for a fridge and storage. I don't know if I would put any doors on it or leave it open. I just do not want to have it built and set up with spaced slats. How would I go about building something that could handle the rain and not rot and warp like crazy?

Thanks tons!

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)