Yesterday I made an Octoberfest that went into the fermenter at 1.061 (5gal). My plan was to pitch two smack packs.

However, one of the packs was a bit older and despite several hours it was barely puffed up. The other pack blew up like a balloon in the same time.

When it came time to pitch, the barely inflated pack contents smelled sorta sulfery and stinky so I did not add that pack. The other pack smelled of normal yeasty goodness.

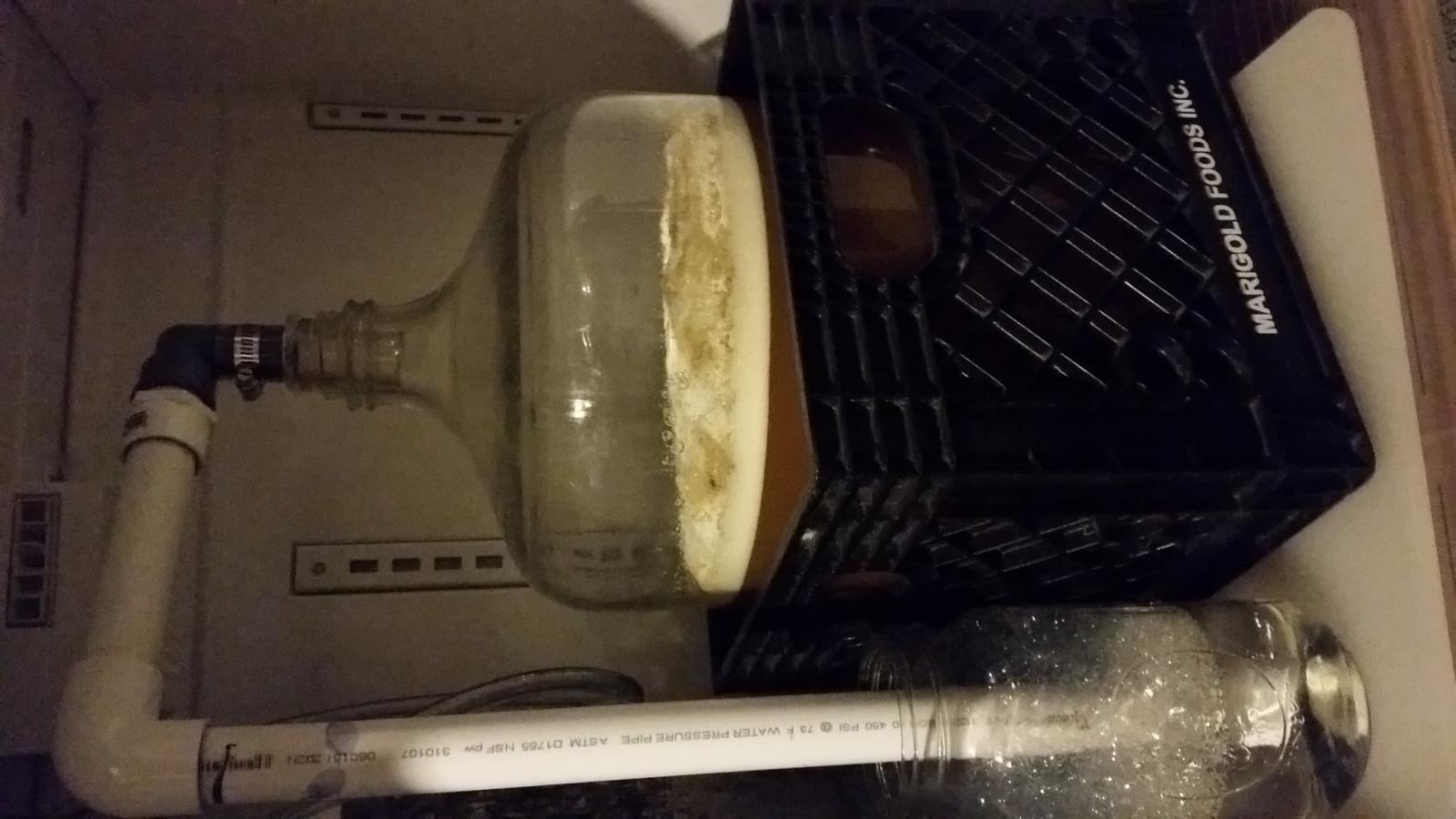

It's been about 18 hours @ 55F and there is some real, real light activity so I'm not worred about a flop.

Just looking for any suggestions on making the best of this somewhat low pitch rate.

However, one of the packs was a bit older and despite several hours it was barely puffed up. The other pack blew up like a balloon in the same time.

When it came time to pitch, the barely inflated pack contents smelled sorta sulfery and stinky so I did not add that pack. The other pack smelled of normal yeasty goodness.

It's been about 18 hours @ 55F and there is some real, real light activity so I'm not worred about a flop.

Just looking for any suggestions on making the best of this somewhat low pitch rate.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)