I am trying to find a good German recipe that I can keep going to. I have been doing 1 gal batches and my last had some awful off flavors. I used 34/70 with 100% vienna malt. My next batch I decided to use S-04 just to see if I can get something drinkable that isn't a kit.

Recipe just because I was messing around. Brewed 2/28/24

Bestmalz Pilsen: 72.3%

Weyermann Munich II: 9.9%

Weyermann Vienna: 9.9%

Weyerman CaraMunich II: 7.9%

6g EKG @60

6g Fuggles @30

6g Fuggles @10

OG 1.059 (BrewFather est 1.054)

FG still going currently 1.017; BF est 1.012

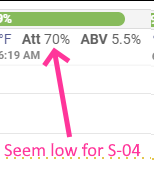

Did my normal BIAB on the stovetop. Put ~1.1g in the LBMB and set in my room to go. Temps 68-71F. Some fluctuations but I didn't figure this much was too far off. I decided to have a small sample and there is a distinct off flavor. Similar to my previous Vienna w/34/70. I thought this was odd so looking for any advice. I'll continue to let it ferment as far down as I can. I was just surprised at the odd flavor using ale yeast. Never had this using kits.

I'd like to experiment more, but at this rate I am wondering what the issue is? My normal batches (Kit only so far) using a GrainFather G40 & Spike Flex+ and no issues. This BIAB mashes with a 2 gal Igloo cooler and standard 2 gal kettle.

Recipe just because I was messing around. Brewed 2/28/24

Bestmalz Pilsen: 72.3%

Weyermann Munich II: 9.9%

Weyermann Vienna: 9.9%

Weyerman CaraMunich II: 7.9%

6g EKG @60

6g Fuggles @30

6g Fuggles @10

OG 1.059 (BrewFather est 1.054)

FG still going currently 1.017; BF est 1.012

Did my normal BIAB on the stovetop. Put ~1.1g in the LBMB and set in my room to go. Temps 68-71F. Some fluctuations but I didn't figure this much was too far off. I decided to have a small sample and there is a distinct off flavor. Similar to my previous Vienna w/34/70. I thought this was odd so looking for any advice. I'll continue to let it ferment as far down as I can. I was just surprised at the odd flavor using ale yeast. Never had this using kits.

I'd like to experiment more, but at this rate I am wondering what the issue is? My normal batches (Kit only so far) using a GrainFather G40 & Spike Flex+ and no issues. This BIAB mashes with a 2 gal Igloo cooler and standard 2 gal kettle.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)