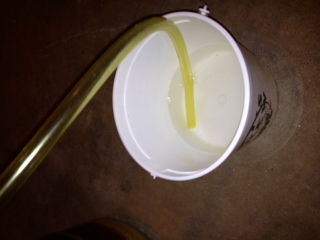

I brewed yesterday (saturday) put my beer into the Carboy at 4pm it's 8:45 PM on Sunday and nothing is blowing out of my overflow. some foamy suds at top of carboy, but not looking like it's doing much.

My yeast was in one of the action packs where you pop the corner and let the bag sit, I only let it sit for 30 minutes.

Also my beer was around 80 degrees when I added yeast.

My yeast was in one of the action packs where you pop the corner and let the bag sit, I only let it sit for 30 minutes.

Also my beer was around 80 degrees when I added yeast.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)