SookeBrewing

Well-Known Member

Today I finished wiring up the PIDs, timer, alarm (buzzer, lights and switches).

Here is a pic of the panel powered up. The volt meter does work, I just knocked a wire loose and didn't bother to hook it back up. Still waiting on a replacement ammeter/voltage converter.

Here, the alarm is going off after the timer counted down - it's awesome to see it working!

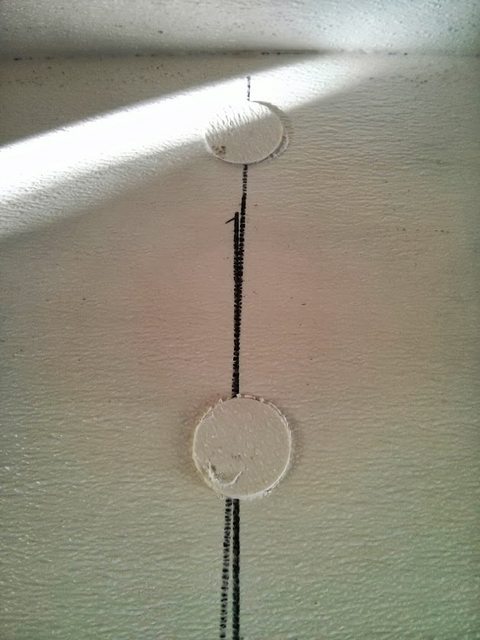

I also received the stainless lock nuts and shims and the high-temp O-rings for my elements. I had one keggle punched and ready so I attached it (unbelievably simple, by the way). I filled it up with water and there are no leaks after a few hours.

If I can figure out how to use my PIDs without a temperature probe (still waiting to order those) I will be able to use my panel to fire my boil and HLT as early as next week!

I will still have to mash in the cooler, since I don't have the HERMS coil/pumps/fittings yet, but it will be fun to brew without that loud propane burner.

Here is a pic of the panel powered up. The volt meter does work, I just knocked a wire loose and didn't bother to hook it back up. Still waiting on a replacement ammeter/voltage converter.

Here, the alarm is going off after the timer counted down - it's awesome to see it working!

I also received the stainless lock nuts and shims and the high-temp O-rings for my elements. I had one keggle punched and ready so I attached it (unbelievably simple, by the way). I filled it up with water and there are no leaks after a few hours.

If I can figure out how to use my PIDs without a temperature probe (still waiting to order those) I will be able to use my panel to fire my boil and HLT as early as next week!

I will still have to mash in the cooler, since I don't have the HERMS coil/pumps/fittings yet, but it will be fun to brew without that loud propane burner.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)