Mirage

Well-Known Member

I was thinking too, if you live in CT, I have some PT 2x10 from when I built my deck that you can have. Not sure what the diameter of your coolers are, but maybe that would work. That stuff lasts a LONG time.

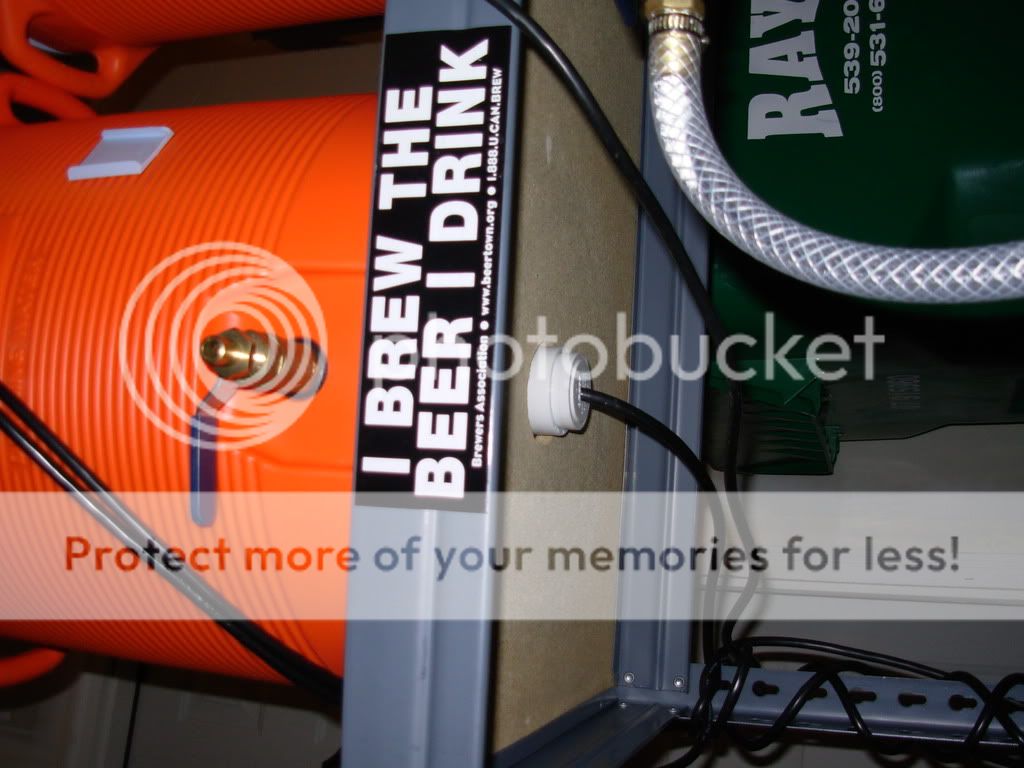

That's clear. The HLT with HERMS coil is on the left, the MLT on the right. You pump out of the mash and into the HERMS coil inlet at the top of the HLT, then back out the top of the HLT via the other end of the coil and into the top of the MLT to the blue knobby hose return. You use gravity to drain the MLT into the BK.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

It will work better than simply striking at one temp and letting it sot for an hour, I am pretty sure of that! It will also be nice to do all of this without burning propane.

A couple questions for you...

You seem to be controlling your mash temp by measuring the HLT temp with your controller. Is that right? Do you find that setting that temp to your desired mash temp actually gives you the ultimate mash temp you want or do you need to go +1 or so?

Using a cooler based mashtun is usually enough to hold temp so what is your motivation for HERMS? It seems that running the pump, stirrer and element during the entire mash is fixing a problem that doesn't exist. Is suppose if you triggered the pump off a mash-based controller and probe, it would only kick on when necessary (probably once during the entire mash).

When you're done mashing and ready to start sparging, do you ramp up your HLT temp via the controller to 168 and continue the HERMS recirc to mash out? I would imagine this is where a slightly stronger element would help because it probably doesn't do 1F rise per minute when heating the sparge water and mash itself from 150-168.

What is that flex MLT return doohicky and where did you get it? I've seen that kind of thing on machining tools for coolant delivery but don't know what to search for to find it.