Hi all,

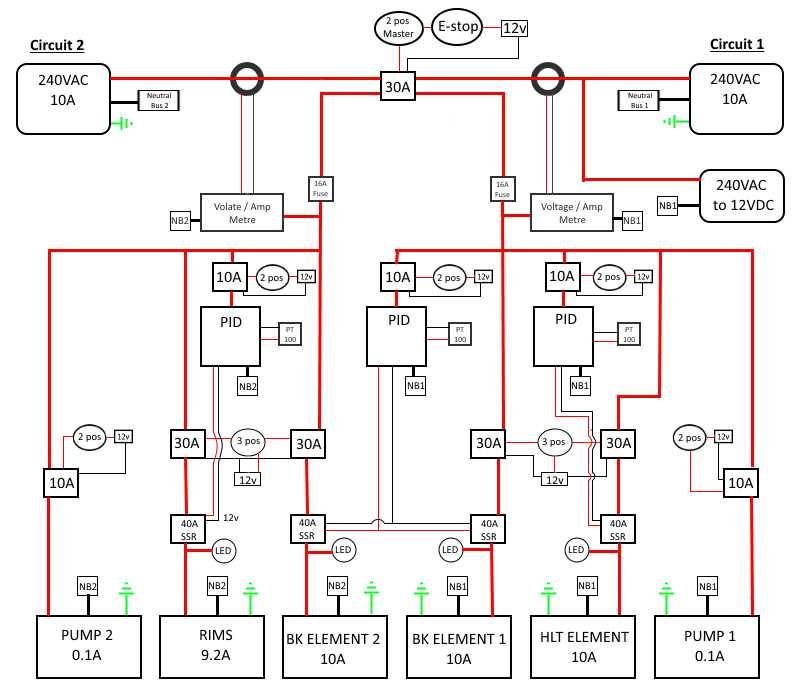

I'm in Australia where the standard house circuits (in our rental place) are 240v nominally 10A (with 16A fuse) with twin and earth.

I'm putting together a electric 3v RIMs system. My system uses two inputs for separate circuits in the house. My system uses 12vdc switches and mechanical relays to switch all of the AC circuitry. Not shown on this image is that the RIMs element switch will be interlocked by a pump to prevent dry firing.

My question is: what sized mechanical relay do I need to use for switching the 2200w heating elements? Will a 10A suffice or do I need to use a larger relay?

I'm in Australia where the standard house circuits (in our rental place) are 240v nominally 10A (with 16A fuse) with twin and earth.

I'm putting together a electric 3v RIMs system. My system uses two inputs for separate circuits in the house. My system uses 12vdc switches and mechanical relays to switch all of the AC circuitry. Not shown on this image is that the RIMs element switch will be interlocked by a pump to prevent dry firing.

My question is: what sized mechanical relay do I need to use for switching the 2200w heating elements? Will a 10A suffice or do I need to use a larger relay?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)