Mikmonken

Well-Known Member

- Joined

- Mar 28, 2013

- Messages

- 423

- Reaction score

- 101

Hi there,

I don't know anything about the CHIP, but if it runs Jessie then it should run Python 3, so my code will run.

Can you hook up the temperature sensors to the CHIP? I am using the w1-gpio driver for those. I am also using the RPi.GPIO driver for the relay pins. You might need to modify the code a little.

Is the CHIP powerful enough to run the webserver too? You need to run BrewPi, and the webserver and my software on the same device, otherwise there's no point.

You are welcome to try.

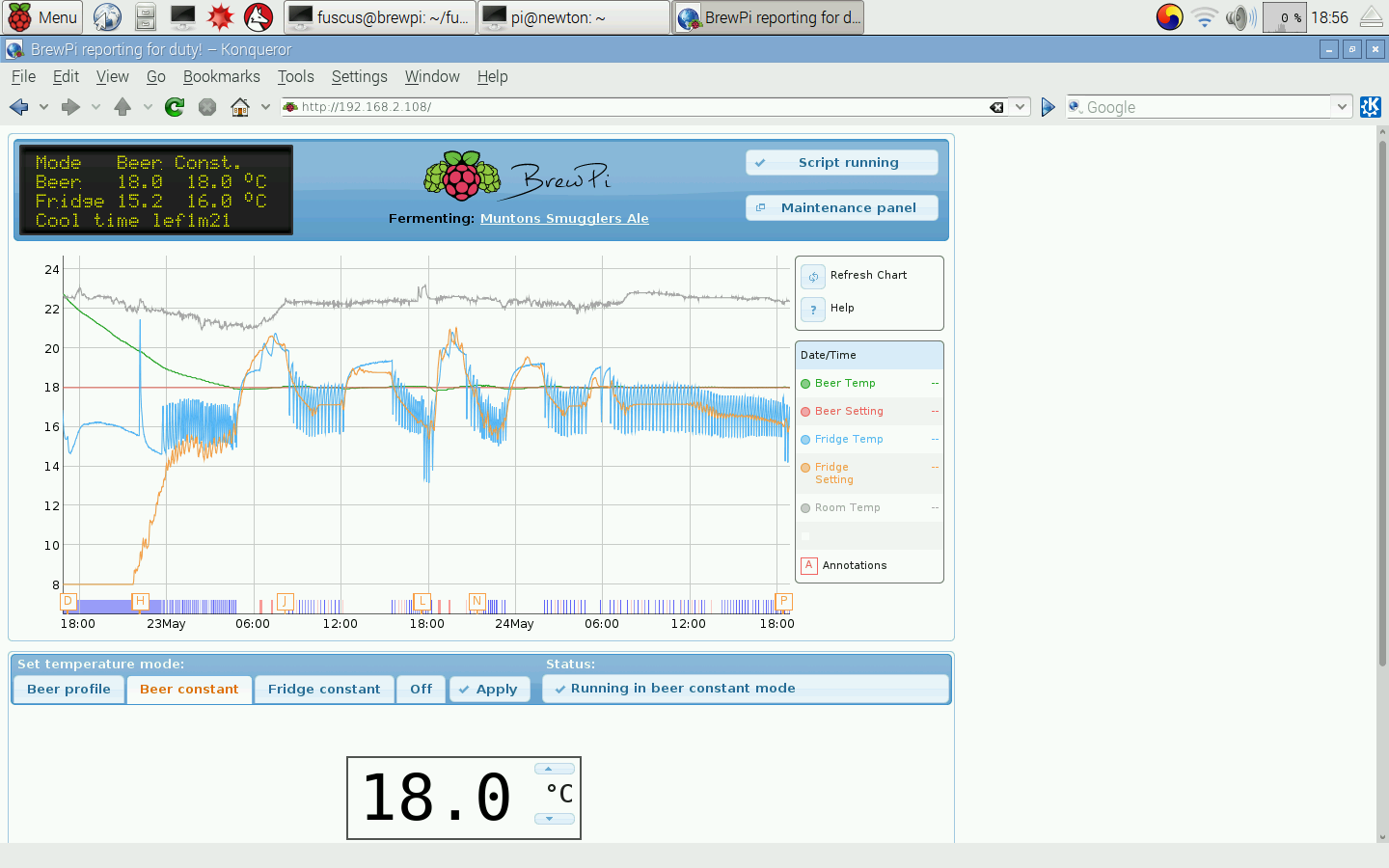

I already managed to get brewpi to run on the chip, so it's capable enough in then sense. I had to do some tweaking to get it installed.

Where I may lack capability is changing the python script. I'm pretty good at following instructions and getting things to work but don't know Python at all.

I'd love to give it a shot though!!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)