You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My single tier build

- Thread starter n2fooz

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Looks real good.

How did you attach the casters?

I welded gussets and drilled holes for stud mount style castors.

Sorry it's blurry but I cropped it from the original pic. It should be good enough for you to get the idea:

Huaco

Well-Known Member

I actually use a 3D program called Solidworks. I haven't modeled the burners or castors but here is a rendering of the stand:

I am a SolidWorks user as well... CSWP actually... What kind of work do you do on SW? (besides designing your own brewstands) haha...

I am a SolidWorks user as well... CSWP actually... What kind of work do you do on SW? (besides designing your own brewstands) haha...

I'm a Product Manager and Industrial Designer. Currently, I work mostly on headphones, earbuds.

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$159.99 ($26.66 / Count)

3M High Flow Series System BREW120-MS, 5616001, For Brewed Coffee and Hot Tea, Valve-in-Head Design

SpaceCityProviders

$28.98

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Great Fermentations of Indiana

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

I am a SolidWorks user as well... CSWP actually... What kind of work do you do on SW? (besides designing your own brewstands) haha...

I thought your name looked familiar. I saw your rendering on this thread and asked what program you were using: https://www.homebrewtalk.com/f51/my...0-some-nice-modifications-172927/index32.html

Good to see a fellow SW user.

Huaco

Well-Known Member

I thought your name looked familiar. I saw your rendering on this thread and asked what program you were using: https://www.homebrewtalk.com/f51/my...0-some-nice-modifications-172927/index32.html

Good to see a fellow SW user.

Sorry man... I did not see your reply to that thread. Yeah, I am on SW2012 and will be heading out to San Diego for SolidWorks World here in a few weeks. I have a little more done to my design, but I want to change some things to reflect the material I have on hand. I need to scrounge up a few pieces of scrap in the yard at work, but I pretty much know what I want to do on my stand (its just in my head) haha...

I work in heavy metal fabrication and use the Weldments tools every day.

I plan to use the conical burners for my stand and want to model some conical wind guards to cut on our plasma table at work...

It's been a little while but I've added the stand-offs. I decided to go with 1/2"x3/4" aluminum bar stock.

I didn't counter-sink the socket head cap screws so that they help prevent the kegs from sliding around.

I didn't counter-sink the socket head cap screws so that they help prevent the kegs from sliding around.

Seen any use yet?

Not yet, I still have plenty of work to do.

Looking mighty fine! I like the socket head cap screws placement for holding the Brew pot / kettles from sliding off during a busy brew day! Can't wait to see the finished product...

Looking mighty fine! I like the socket head cap screws placement for holding the Brew pot / kettles from sliding off during a busy brew day! Can't wait to see the finished product...

Thanks! Thanks for the idea too.

I can't wait to finish it.

n2fooz said:I welded gussets and drilled holes for stud mount style castors.

Sorry it's blurry but I cropped it from the original pic. It should be good enough for you to get the idea:

Hey n2fooz,

My build as progressed to the point where I'm looking to attach casters, and I'm thinking of doing exactly what you did.

Couple questions --

- from the picture, it looks like you cut a steel bar to fit, and welded that in, or did you get a larger steel plate and cut it to fit?

- How thick is that piece?

- Confident that it will hold (obviously, but is there any doubt)?

- Is it easy enough to using the locking mechanisim, being mounted that far inside the stand?

These answers will help immensely. Thanks!

Hey n2fooz,

My build as progressed to the point where I'm looking to attach casters, and I'm thinking of doing exactly what you did.

Couple questions --

- from the picture, it looks like you cut a steel bar to fit, and welded that in, or did you get a larger steel plate and cut it to fit?

- How thick is that piece?

- Confident that it will hold (obviously, but is there any doubt)?

- Is it easy enough to using the locking mechanisim, being mounted that far inside the stand?

These answers will help immensely. Thanks!

It was pretty simple. 2in flat bar cut at 45 on each end. Once welded in there is no way they are going to fail.

As far as locking the casters, I have no issues.

n2fooz said:It was pretty simple. 2in flat bar cut at 45 on each end. Once welded in there is no way they are going to fail.

As far as locking the casters, I have no issues.

Thanks. Do you recall how thick that bar is?

Grzebyk26

Active Member

I really like this brewstand and I am thinking about making one just like it. Can you list all the parts that you used for you propane setup please. thank you.

raptorvan

Well-Known Member

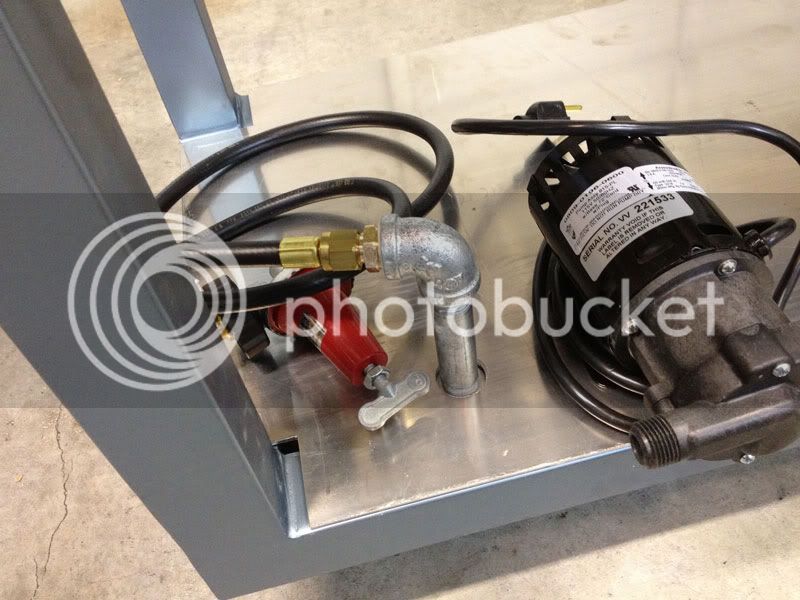

Excuse my ignorance...but from the picture it looks like quick connects? If that is the case, why use more than one pump?

Grzebyk26

Active Member

I know that those are quick disconnects. On the previous page was a picture of the propane system. sorry for being unclear.

I really like this brewstand and I am thinking about making one just like it. Can you list all the parts that you used for you propane setup please. thank you.

Unfortunately I don't have a listing of all the parts. I used 3/8" compression fittings with flexible copper tubing from Home Depot. It was a lot of work and if I did it over again I'd probably just order the custom hoses from ONEHOPPYGUY.

To use the compression fittings you need a flaring tool:

The copper is flexible but it was a pain to get lined up and leak free.

Grzebyk26

Active Member

Thanks for the advice I reallt appreciate it.

I'm jumping back to the start of this post. I cut metal all day long, its my job. I work mostly with aluminum but also steel. Steel should be cut at low RPMs. Speed adjustments or a steel saw are ideal for cutting steel. They also make "abrasive" blades (basically a huge grinder disc) that work well at higher rpms. The abrasive discs cost under $10 for my company and can be installed on a standard chop saw.

Your cuts and welds look excellent, and they cleaned up so nice. I hope the build go smoothly!

Your cuts and welds look excellent, and they cleaned up so nice. I hope the build go smoothly!

dutchoven

Well-Known Member

Plate chiller...

Nice setup on the chiller ... I like the thermo mount ... Which model chiller? Duda, I assume?

Similar threads

- Replies

- 44

- Views

- 2K

- Replies

- 1

- Views

- 733

- Replies

- 14

- Views

- 675

- Replies

- 5

- Views

- 999

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)