Drk93TT

Well-Known Member

- Joined

- Feb 27, 2014

- Messages

- 274

- Reaction score

- 27

I keep having issues BOTH with low OG and low efficency percentage.

On 3rd all grain batch now. All grain is crushed at a well known LHBS. I have been fly sparging all 3 batches.

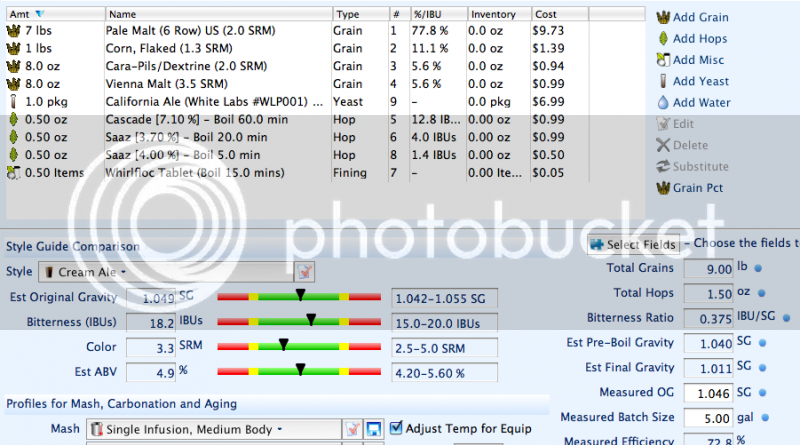

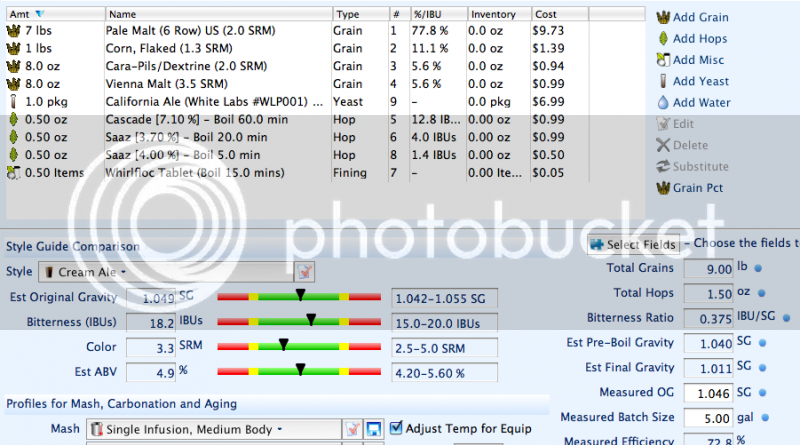

The last batch I did (which is what I will focus on in this post)was a cream ale that Beersmith says should be OG of 1.049 at 77% Tot Eff.

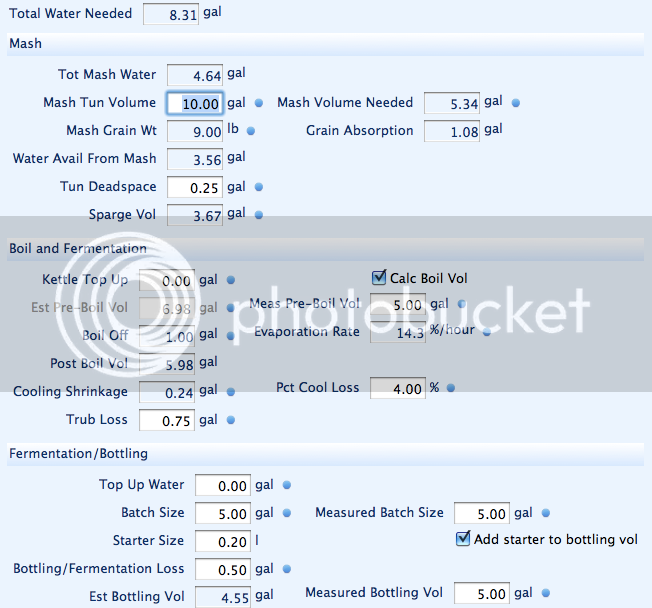

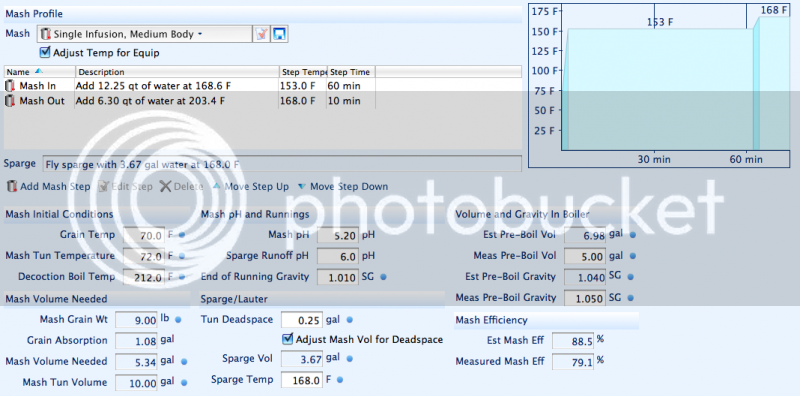

Water volumes.. 3.060 Strike,1.575 mashout,3.67 sparge. Heres a pic of the stats.

Major Equipment list:

10 gallon igloo MLT with AIH False bottom

Colander strainer for fly sparging

10 gallon boil kettle

8 gallon sparge kettle

Thermapen to monitor temps

All silicone hoses for transfers

Propane burner

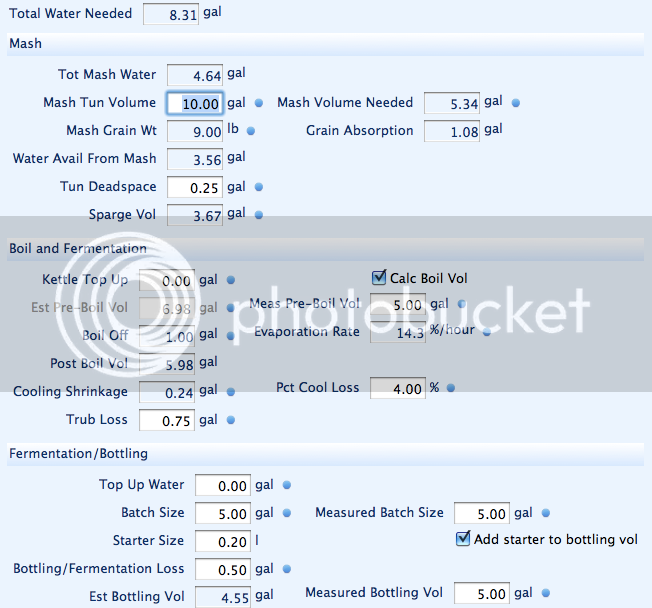

Pic of grain bill recipe / beersmith

Brew day PROCESS---->

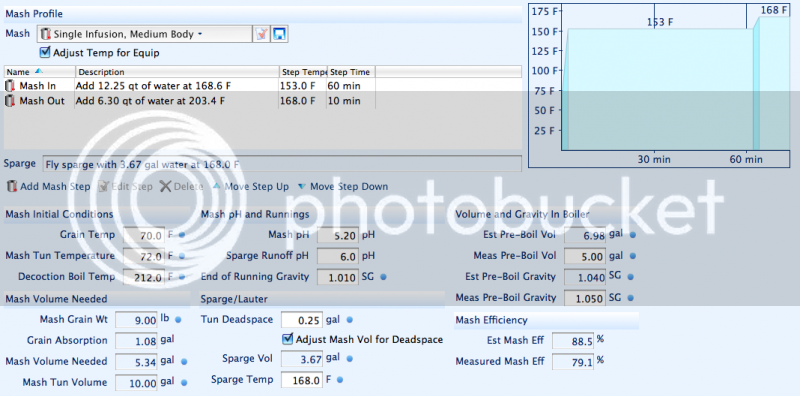

-Strike water to preheat MLT at 185* (preheated for 10 mins) Stirred and left lid off to let temp stabilize to 168*F Before adding grain slow and stirring.

-I did a 60 min mash at a measured a solid 153 * F right away. Closed up and wrapped with blanket a full 60 mins. At the end of the 60 mins the MLT brew temp was a LOW 135 * F . This is when I added 1.5 gallons of 205*F mashout water.

-When I added the water I tried my best to not dump it in too fast, but it did disturb the grain bed I think as I saw grain floating up in different spots occasionally. (this is the FIRST beer ive used a mashout step on and the WORST measured efficiency yet)

-The temp did in fact rise to 168* after mashout water added in step like beersmith says its supposed to.

-Closed back up for 10 mins at 168* mlt temp

-Checked for converison, confirmed with drop of iodine in husk free wort

-Vorlauf couple pitchers until clear wort and no husky rubbish comin' thru

*** I have NEVER taken gravity readings of any runnings during mash process... Im unsure if this wouldve helped/unsure of process/when to do so ***

-At this point I gravity fed my HLT sparge water slow into my strainer on top of MLT. ( I even monitored temp and adjusted as needed with flame under HLT to maintain temp 166-168 for christ sake) I open both valves SLOW and equally. I sparged for a FULL ~70 mins until all sparge water ran into boil kettle. I keep a good 2 inches of sparge water above the grain bed at all times.

Sparging pic............

-Began boil as usual blah blah 60mins vigorous boil with 3 timed hop additions.

-Chilled wort with my immersion chiller in ~12 mins to 70*F. Wort has lots of chunky hops floating around in it I noticed.. probably normal haha just noticed more because Im brewing outside today.

**********************************

Did not end up with 5 gallons.. more like just under 4.8 in the bucket

AAAAAnnd..

My OG measured was 1.034 (at 70*F w thermapen in sample) My last OG's have been short by 6-8 points this is the shortest so far..... again. Sample tastes pretty overly sweet/prickly at the moment. and kind of bitter....

My OG measured was 1.034 (at 70*F w thermapen in sample) My last OG's have been short by 6-8 points this is the shortest so far..... again. Sample tastes pretty overly sweet/prickly at the moment. and kind of bitter....

Even worse my calculated brewhouse efficiency comes in at a whopping 53%... My last couple AG batches like this measured efficiencies of 67% and 68%

Aerated vigorously (shook) and pitched my entire yeast starter (Made the day before sits on a stir plate at least18hrs before pitching)

It has been in a now brand new sealed plastic fermenter with a fermometer on it sitting at ~74 degrees on the gauge.. theres been no bubbles ive seen yet in 24 hrs in the airlock.. although the one side has more water so maybe its a sllloowww bubble. (sidenote: I understand this doesnt mean its not fermenting ... There HAS to be activity and fermentation because I have a carboy right next to it with a beer thats been in it for 10 days fermenting in same room that its fermometer reads 66-68. All my beers in the past have taken off and been bubbling like crazy after 24-36 hours. This one puzzles me.

Am I doing something wrong? I dont get it. Frustrating.... I clean very well and have good sanitation.. Oxi clean free and Star-San. Thanks for reading. Any help greatly appreciated. Hope its a minor change to my process which I thought was pretty good.. Maybe I just need to Batch sparge.. which I haven't done yet surprisingly.. I enjoy Fly sparging , just not the results of this batch.

On 3rd all grain batch now. All grain is crushed at a well known LHBS. I have been fly sparging all 3 batches.

The last batch I did (which is what I will focus on in this post)was a cream ale that Beersmith says should be OG of 1.049 at 77% Tot Eff.

Water volumes.. 3.060 Strike,1.575 mashout,3.67 sparge. Heres a pic of the stats.

Major Equipment list:

10 gallon igloo MLT with AIH False bottom

Colander strainer for fly sparging

10 gallon boil kettle

8 gallon sparge kettle

Thermapen to monitor temps

All silicone hoses for transfers

Propane burner

Pic of grain bill recipe / beersmith

Brew day PROCESS---->

-Strike water to preheat MLT at 185* (preheated for 10 mins) Stirred and left lid off to let temp stabilize to 168*F Before adding grain slow and stirring.

-I did a 60 min mash at a measured a solid 153 * F right away. Closed up and wrapped with blanket a full 60 mins. At the end of the 60 mins the MLT brew temp was a LOW 135 * F . This is when I added 1.5 gallons of 205*F mashout water.

-When I added the water I tried my best to not dump it in too fast, but it did disturb the grain bed I think as I saw grain floating up in different spots occasionally. (this is the FIRST beer ive used a mashout step on and the WORST measured efficiency yet)

-The temp did in fact rise to 168* after mashout water added in step like beersmith says its supposed to.

-Closed back up for 10 mins at 168* mlt temp

-Checked for converison, confirmed with drop of iodine in husk free wort

-Vorlauf couple pitchers until clear wort and no husky rubbish comin' thru

*** I have NEVER taken gravity readings of any runnings during mash process... Im unsure if this wouldve helped/unsure of process/when to do so ***

-At this point I gravity fed my HLT sparge water slow into my strainer on top of MLT. ( I even monitored temp and adjusted as needed with flame under HLT to maintain temp 166-168 for christ sake) I open both valves SLOW and equally. I sparged for a FULL ~70 mins until all sparge water ran into boil kettle. I keep a good 2 inches of sparge water above the grain bed at all times.

Sparging pic............

-Began boil as usual blah blah 60mins vigorous boil with 3 timed hop additions.

-Chilled wort with my immersion chiller in ~12 mins to 70*F. Wort has lots of chunky hops floating around in it I noticed.. probably normal haha just noticed more because Im brewing outside today.

**********************************

Did not end up with 5 gallons.. more like just under 4.8 in the bucket

AAAAAnnd..

Even worse my calculated brewhouse efficiency comes in at a whopping 53%... My last couple AG batches like this measured efficiencies of 67% and 68%

Aerated vigorously (shook) and pitched my entire yeast starter (Made the day before sits on a stir plate at least18hrs before pitching)

It has been in a now brand new sealed plastic fermenter with a fermometer on it sitting at ~74 degrees on the gauge.. theres been no bubbles ive seen yet in 24 hrs in the airlock.. although the one side has more water so maybe its a sllloowww bubble. (sidenote: I understand this doesnt mean its not fermenting ... There HAS to be activity and fermentation because I have a carboy right next to it with a beer thats been in it for 10 days fermenting in same room that its fermometer reads 66-68. All my beers in the past have taken off and been bubbling like crazy after 24-36 hours. This one puzzles me.

Am I doing something wrong? I dont get it. Frustrating.... I clean very well and have good sanitation.. Oxi clean free and Star-San. Thanks for reading. Any help greatly appreciated. Hope its a minor change to my process which I thought was pretty good.. Maybe I just need to Batch sparge.. which I haven't done yet surprisingly.. I enjoy Fly sparging , just not the results of this batch.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)