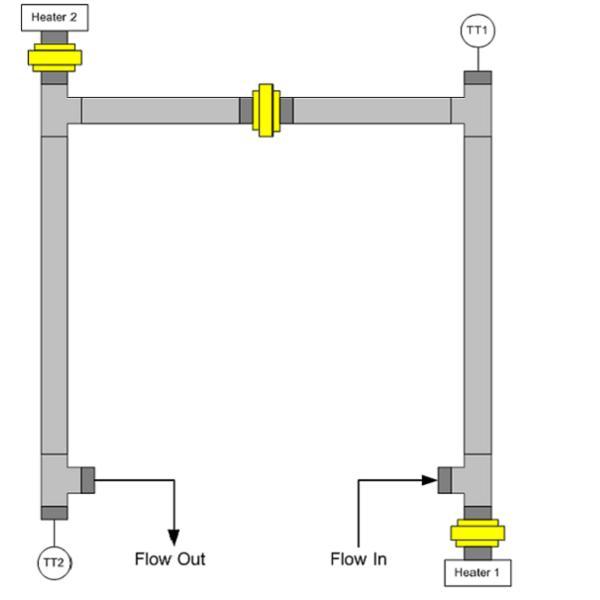

Gonna build another RIMS. I'm adding a second element. Going with 1.5" pipe this time. Also going with Tri-Clamp fittings (the yellow thing-a-ma-bobs) for easy removal for cleaning reconfiguring.

With this system I can split it and use one half for 5-10 gallon batches or keep it as is for 10-15 gallon batches. If I need to do a larger batch, I will use two mash tuns, split this unit and be able to use a RIMS on both mash tuns! I can also lend a half to a brewing buddy (for a small beer fee of course).

With this system I can split it and use one half for 5-10 gallon batches or keep it as is for 10-15 gallon batches. If I need to do a larger batch, I will use two mash tuns, split this unit and be able to use a RIMS on both mash tuns! I can also lend a half to a brewing buddy (for a small beer fee of course).

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)