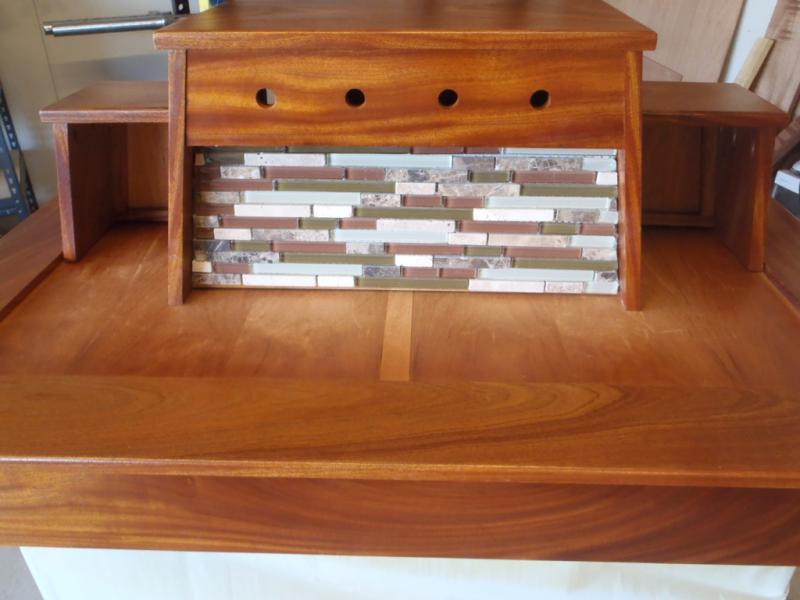

Wow this is a beautiful build. I am curious, why did you want to add the collar to the Keezer?

Looking forward to seeing the finished build.

Looking forward to seeing the finished build.

2 Reasons really...I wanted to add a little more head space to fit a 10# CO2 bottle (on the compressor shelf) and I also couldn't bring myself to cut up the lid of the brand new freezer. If this design turns out to be problematic, I can try again with the original lid.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

Wow! Terrific job. How many hours in total do you have into that bad boy?

I'm letting it cool now and will check the temps in at each location periodically.

Nice progress so far.

I've often wondered why everyone that builds a coffin-style keezer usually only puts two small holes to allow air to pass through. Wouldn't it be better to have the entire bottom of the coffin open to the freezer compartment, and then just drop a fan down below to push up air towards the opening?

You may want to hook up a tube so that the out intake is located at the top (heat rises). You may get a more uniform temp in the coffin that way.

those LED lights......information on them?

Looks good

Is the wood against the sheet metal? If it is it won't allow the coils to cool properly and it will over heat and shorten the life of the freezer. If you put your hand on the skin of a working freezer you will feel that it is warm, this is what cools the refrigerant before it goes back into the compressor.

I am guessing here because my set up is different but I don't think you need a hose to pull up the lower colder air into the coffin. Just the air being sent back into the freezer from the coffin should be enough to stir up the air.

I cant tell from the pics but do you have a lot of dead space in the coffin or did you fill most of it up with insulation?

If you have a lot of dead space I would insulate the middle of the coffin below the shanks creating a lower case "n" shaped channel. With a fan mounted to the channel, it will pull the cold air up into the coffin, over the shanks and back down to the freezer. The channel diameter will also dictate the air flow rate.

I would not be too concerned with the temp at the shanks. Look more at the temp of the beer coming out of them and whether you are getting a lot of foam.