branCHEs

Well-Known Member

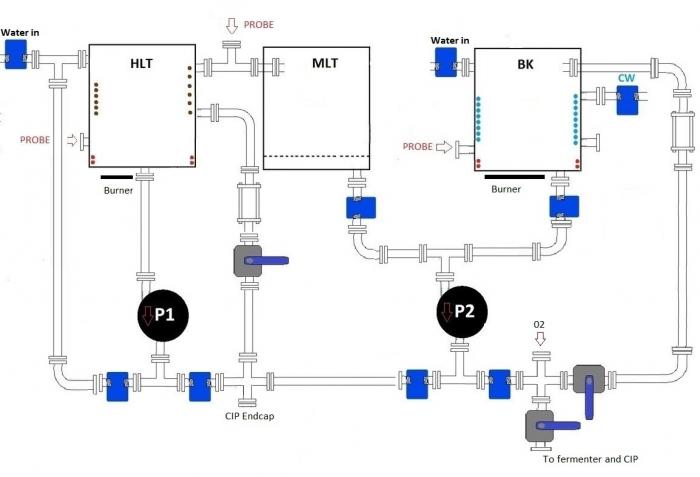

kickflip_mj said:The parts list is almost non existent because of how expensive and how many connections there are, when I get done with some stuff I will start.

Yeah i can imagine... I only ask because someday i want to build the ultimate set up my self and i like what you got going on. I will be following until the end!

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)