Update: I finished my new chalkboard and included the custom pint glasses that my wife gave me for Father's Day.

Thanks to Quaffer for his build and my inspiration. Thanks to others that have answered various questions and supplied tips. This is built from the black Frigidaire 7.2 cu ft freezer that I bought at Lowe's over the summer. It sat in my basement until about a month ago. I did not realize how much time it would take to build it the way that I envisioned. However, it's been a lot of work and a lot of fun. As a woodworker (hobbyiest), I wanted the wood portions of the build to stand out, so I selected a thin skin (1/8") birdseye maple to wrap the 2x10 (cut down to 8.5") collar. I also turned my own tap handles. Originally, I turned 4 from cocobolo, but then realized that I wanted 1 to stand apart for the single soda line, so I turned another one from figured maple.

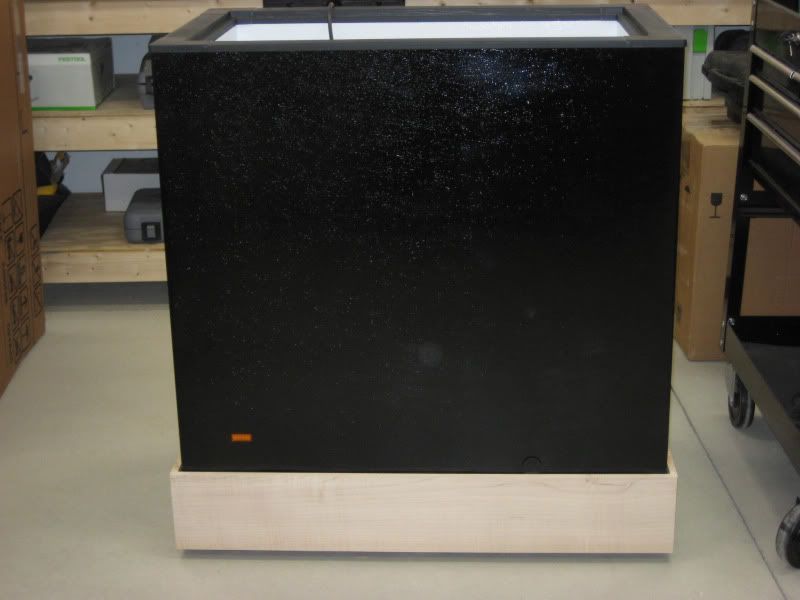

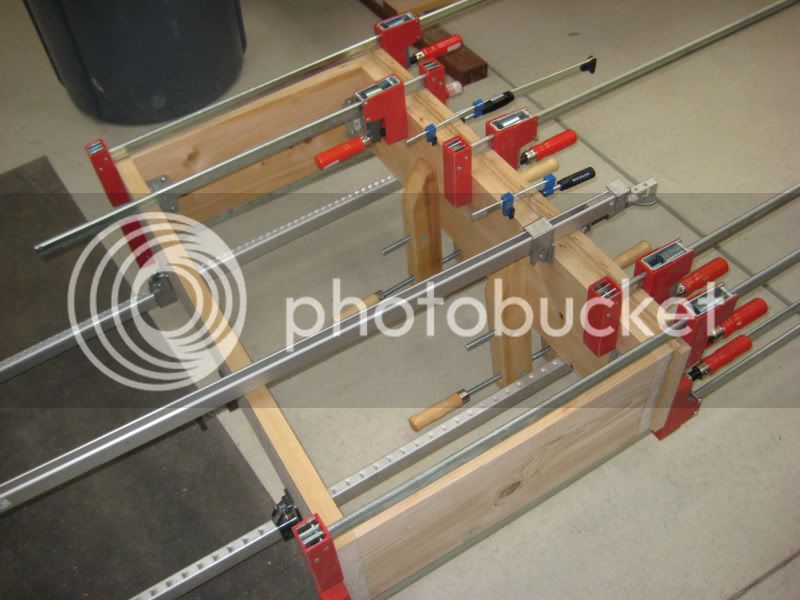

Not employing a tap tower, I wanted to get the height of the keezer to a comfort level for pouring, so I built a base and installed 3" casters. I didn't want to see the casters, so I inset them.

I wanted to further strengthen the base, so I attached some braces. You can see how I inset the casters so that they could swivel and just clear the maple base trim.

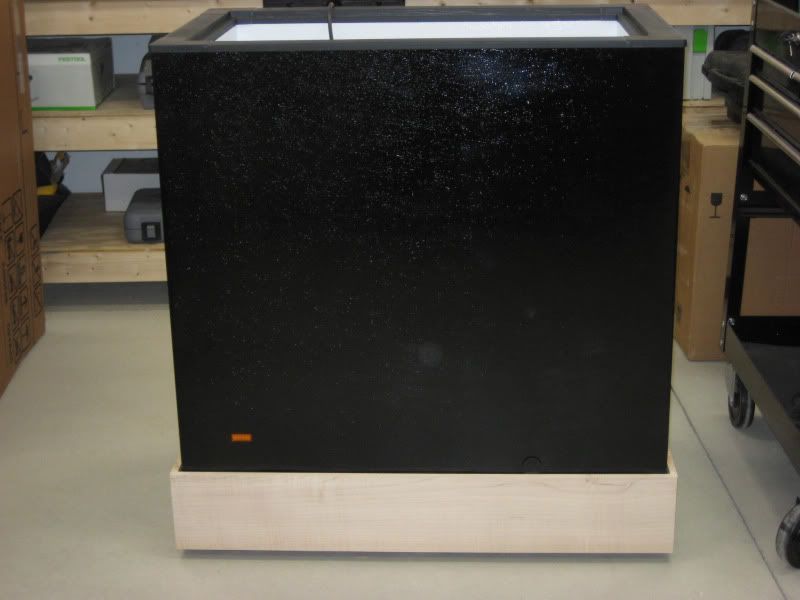

Here is how it stands.

Next up, turning my tap handles on my Jet mini lathe.

Finished sanding with 400 grit, Used some EEE Ultrashine and Shellawax (thanks Joe). Next, I drilled the handle to insert the chrome ferrule and stud.

Here's the birdseye maple I bought off Ebay. Beautiful figure. I bought enough to wrap all 4 sides, but I only did the front and sides since the back will be against the wall.

Thanks to Quaffer for his build and my inspiration. Thanks to others that have answered various questions and supplied tips. This is built from the black Frigidaire 7.2 cu ft freezer that I bought at Lowe's over the summer. It sat in my basement until about a month ago. I did not realize how much time it would take to build it the way that I envisioned. However, it's been a lot of work and a lot of fun. As a woodworker (hobbyiest), I wanted the wood portions of the build to stand out, so I selected a thin skin (1/8") birdseye maple to wrap the 2x10 (cut down to 8.5") collar. I also turned my own tap handles. Originally, I turned 4 from cocobolo, but then realized that I wanted 1 to stand apart for the single soda line, so I turned another one from figured maple.

Not employing a tap tower, I wanted to get the height of the keezer to a comfort level for pouring, so I built a base and installed 3" casters. I didn't want to see the casters, so I inset them.

I wanted to further strengthen the base, so I attached some braces. You can see how I inset the casters so that they could swivel and just clear the maple base trim.

Here is how it stands.

Next up, turning my tap handles on my Jet mini lathe.

Finished sanding with 400 grit, Used some EEE Ultrashine and Shellawax (thanks Joe). Next, I drilled the handle to insert the chrome ferrule and stud.

Here's the birdseye maple I bought off Ebay. Beautiful figure. I bought enough to wrap all 4 sides, but I only did the front and sides since the back will be against the wall.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)