Can someone explain to me how terminal blocks work?

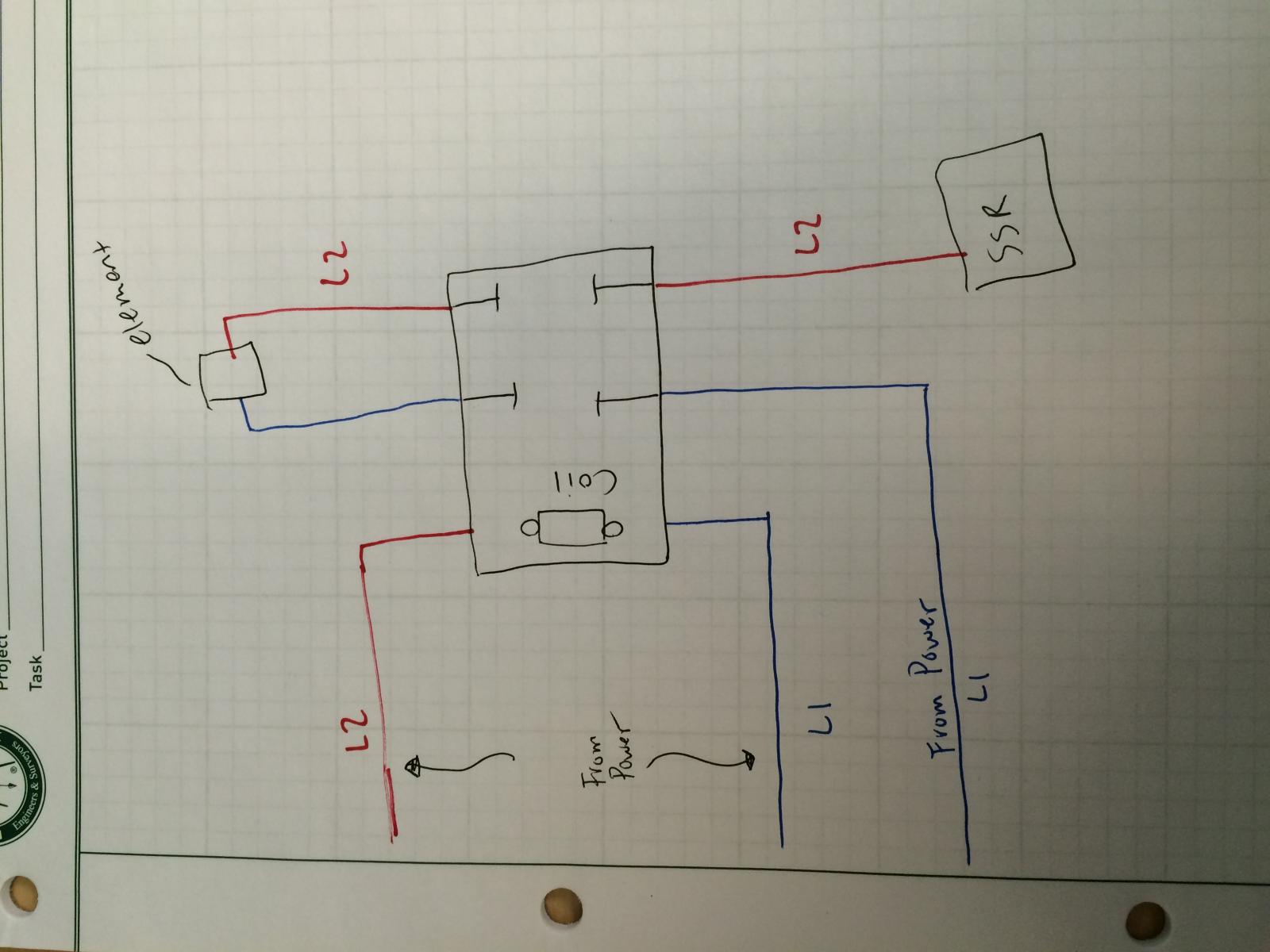

In my mind I'm hoping they work like a splitter. Like one hot leg can be attached then just plug in any wire that needs to branch off that hot leg.

Is that how they work?

I've seen a ton of them on eBay for cheap, but the descriptions seem to state they insulate one wire from another?

Would that mean I would need a jumper? Or what is the purpose of a jumper?

I want to use these terminal blocks if possible to make the innards of my panel nice and neat!

I cannot speak for how they are used in the panels but in a general electrical terms:

Terminal blocks are used for multi-tap connections to a shared source. The example most of us in the US can relate to is the ground and neutral bus bars in our breaker panels.

In certain parts of Europe, terminal blocks are used for all household connections. My favorites are the ones I used in Germany that push-in, 1/4-turn release. Instead of wire nuts terminal blocks are used in the fixture box.