Desert_Sky

Since 1998

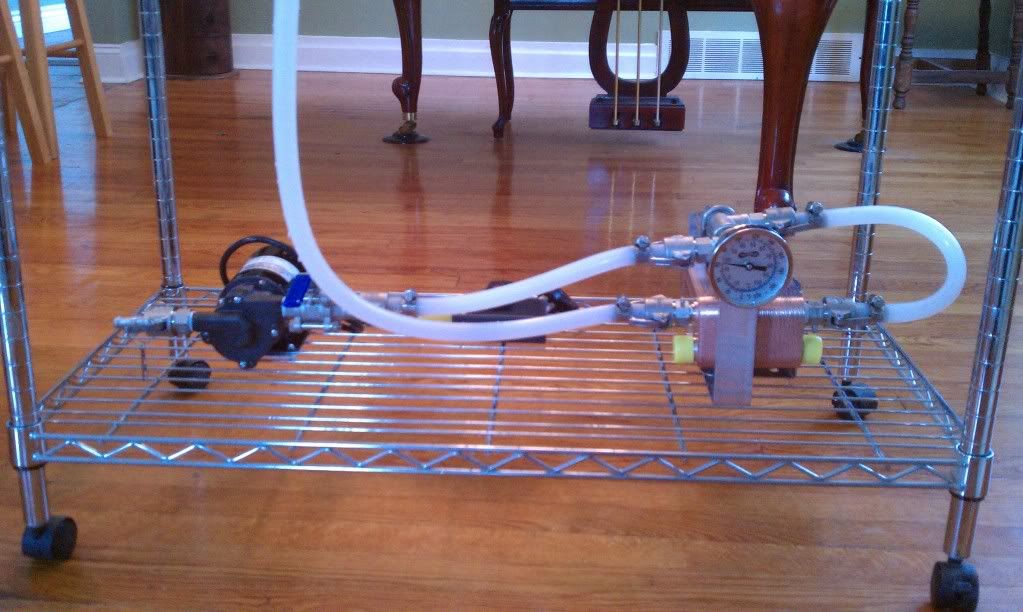

Ok just tested it out finally. I took the day off work to prep and get ready for tomorrow. Gave the chiller a boiling PBW run, then hook up hot water as I pumped into my Blichmann. Chilled boiling water down to 65 with the flow throttled back to a little less than half way open

Now the oxygen stone did let some water through if it the flow was wide open or if it was pumping into a closed tri-clamp on the fermenter.... which of course promptly trips the GFI from dripping directly into the pump. YEa that was fun.....but good to know safety devices are working properly.

Brewing my house pale tomorrow morning which is the chiller, 2050, and the conical's inaugural run. SHould be fun!

Now the oxygen stone did let some water through if it the flow was wide open or if it was pumping into a closed tri-clamp on the fermenter.... which of course promptly trips the GFI from dripping directly into the pump. YEa that was fun.....but good to know safety devices are working properly.

Brewing my house pale tomorrow morning which is the chiller, 2050, and the conical's inaugural run. SHould be fun!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)