Truth time: I only clean my fermenter about every 8 brews (or when something goes wrong) reusing the same yeast over and over.

I’m no flavor expert but I very much enjoy the beer I make. I don’t usually detect any off flavors.

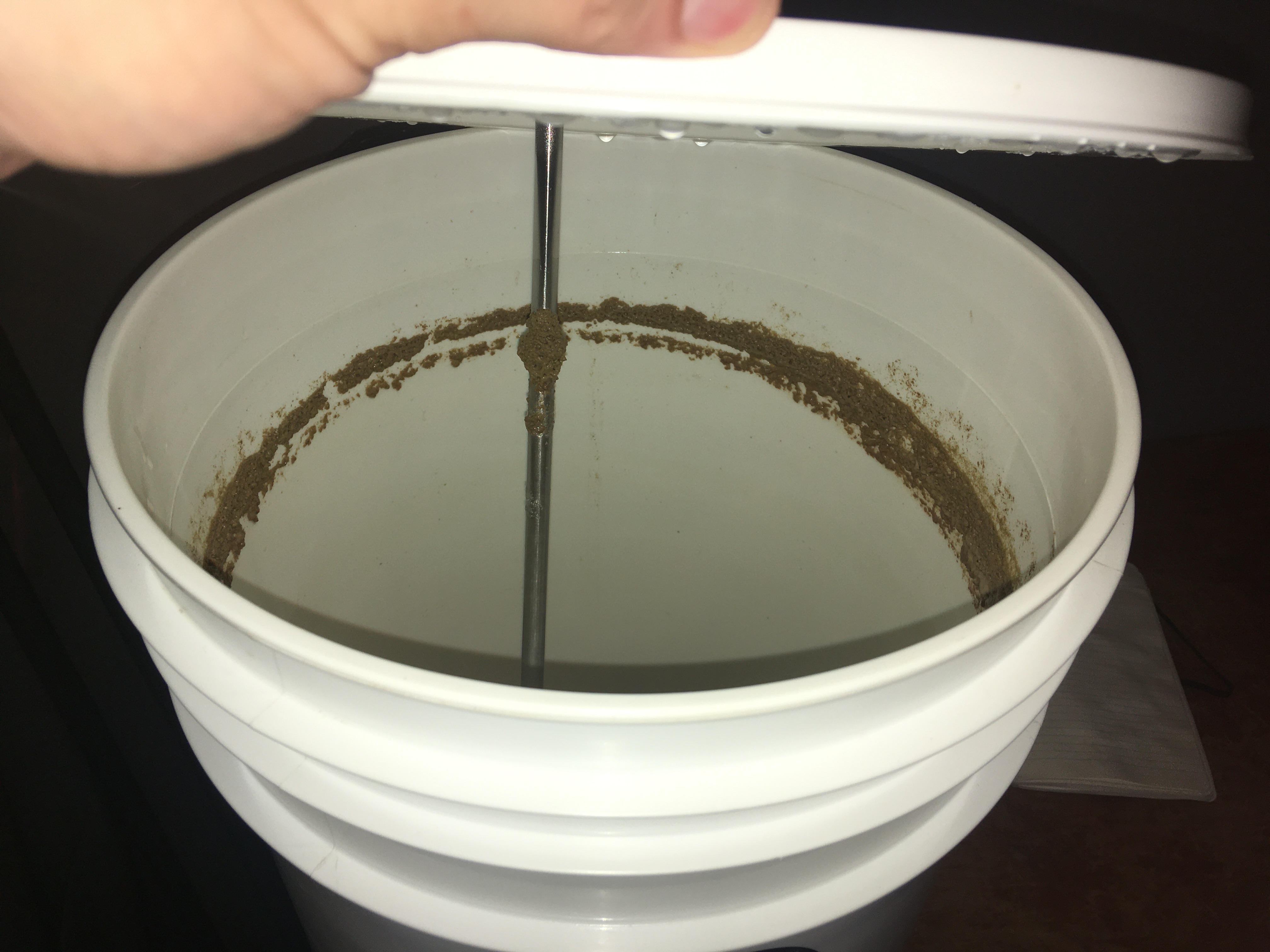

I brew the same lager about every two weeks and just pitch the wort on top of the old yeast cake without cleaning the inside of my Ale Pail. After two brews, I have to scoop out the accumulated yeast at the bottom, usually with a sanitized coffee cup or something or else I end up with a blow over. A 1/4”-1/2” of cake is what I’m going for.

I’ve learned to swap out the spigot because any wort or beer not available to the yeast on the “wrong” side of the valve is vulnerable to bacteria and mold: terrible surprise when it’s time to rack. Other than that, I try to be very careful about keeping the outside clean. Any spots/dirt get a scrub and spray of sanitizer. The fermentation chamber (a box made of rigid foam insulation) is also kept clean/sanitized.

I use a hop spider and whirlpool, trying hard to only transfer clear wort into the bucket.

I love reusing my yeast and the effort saved from one less thing to clean.

I’m clearly a “certain type” of brewer. I’m sure some folks will say they would never even try it but I just had to get that off my chest. Thanks, guys!

I’m no flavor expert but I very much enjoy the beer I make. I don’t usually detect any off flavors.

I brew the same lager about every two weeks and just pitch the wort on top of the old yeast cake without cleaning the inside of my Ale Pail. After two brews, I have to scoop out the accumulated yeast at the bottom, usually with a sanitized coffee cup or something or else I end up with a blow over. A 1/4”-1/2” of cake is what I’m going for.

I’ve learned to swap out the spigot because any wort or beer not available to the yeast on the “wrong” side of the valve is vulnerable to bacteria and mold: terrible surprise when it’s time to rack. Other than that, I try to be very careful about keeping the outside clean. Any spots/dirt get a scrub and spray of sanitizer. The fermentation chamber (a box made of rigid foam insulation) is also kept clean/sanitized.

I use a hop spider and whirlpool, trying hard to only transfer clear wort into the bucket.

I love reusing my yeast and the effort saved from one less thing to clean.

I’m clearly a “certain type” of brewer. I’m sure some folks will say they would never even try it but I just had to get that off my chest. Thanks, guys!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)