Hey everyone. Have a question for who'll ever listen.

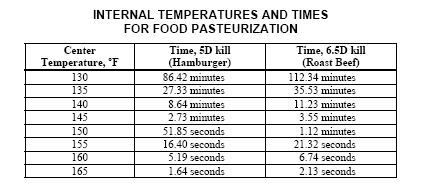

I brewed a old ale about 10 days ago, this was the first time I was able to use a direct heat mash in my setup, I was excited. I had derived via Palmer's "How to Brew" website that I should jump full into this process and take advantage of several "rest" points on my way to wort. My reading of his material lead me to concluded that it was to my benefit to pause for a certain amount of time in a prime Beta-Amalyse temp zone (140) and then jump up to the prime Alpha-Amalyse zone (158).

Anyways I spent about 45 minutes at 140-145 and then about 25 minutes at 156-160, then mashed out and drained the kettle. I boiled and finished as I usually do, got an extremely efficient end result, dumped it into my fermenting vessel, and pitched the yeast (starter prepared) and watched it over the next few days go nuts. I though I was all set.

I took a gravity reading after about 7 days (about 2 days after the bubbly furry had subsided) and it looks like I've gotten about 35% apparent attenuation from my WLP099 high gravity yeast, instead of the 85+ I was expecting.

So my question(s) is/are:

1) Does it benefit a mash to rest a bit in the beta zone first, then in the alpha zone

2) Should I be concerned that after 5 days of fermentation I've only achieved 35%?

3) Did I rest to low for beta, and therefore convert all my sugar into non-fermentables?

4) Is there anything I can do about that (if it is the case) other than wait?

What are your fermentation temperatures?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)