Yesterday I picked up some used CO2 bottles, regulators, and kegs. Some of the stuff is beautiful, but I still plan to refurbish what I can.

The question is, how do people usually screw this up? What mistakes are common?

Thank you for sharing your hard earned advice and warning!

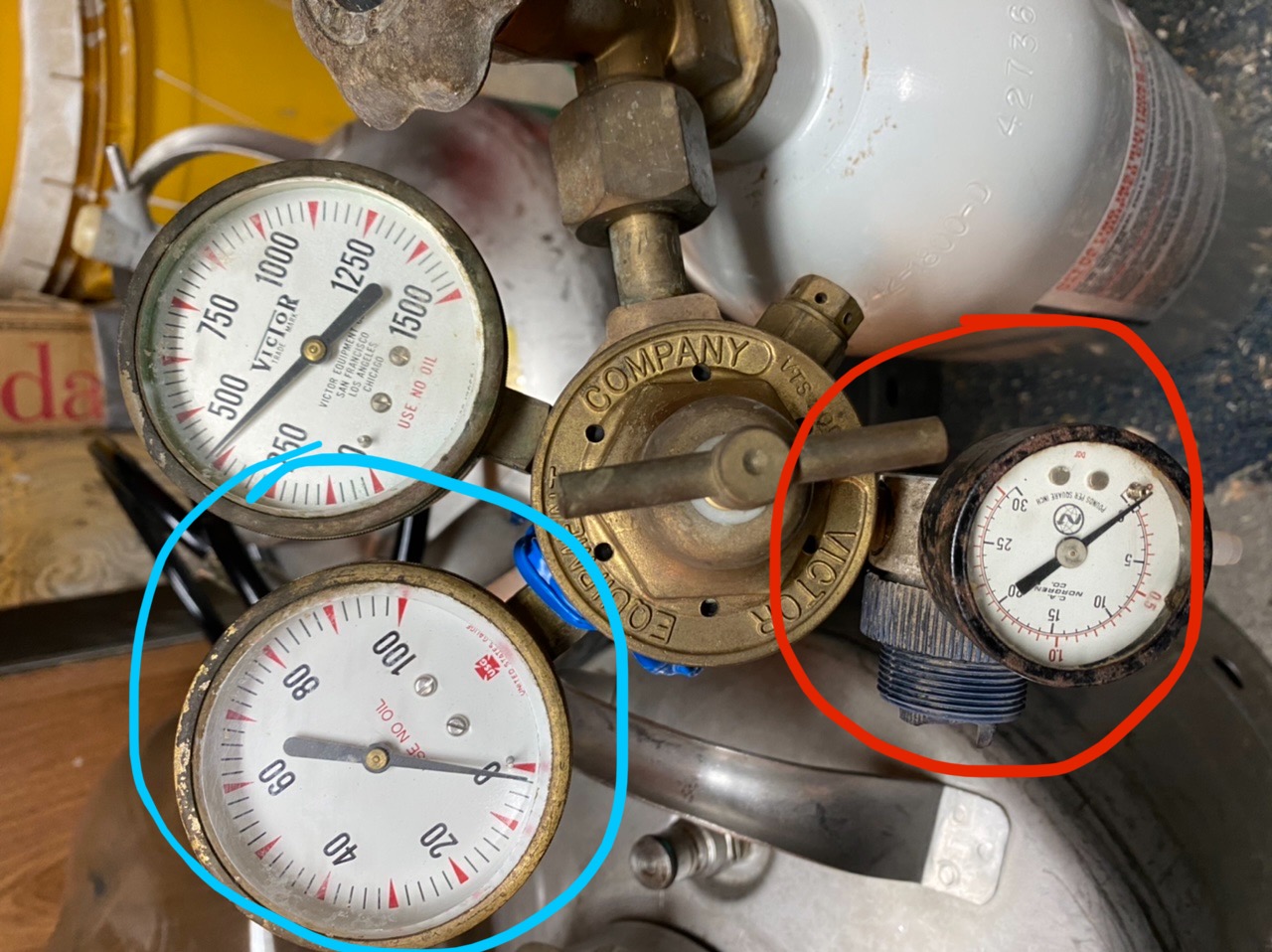

(pictures attached for fun)

The question is, how do people usually screw this up? What mistakes are common?

Thank you for sharing your hard earned advice and warning!

(pictures attached for fun)

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)