Mike123

Well-Known Member

Somehow the site stopped alerting me to replies to this thread.

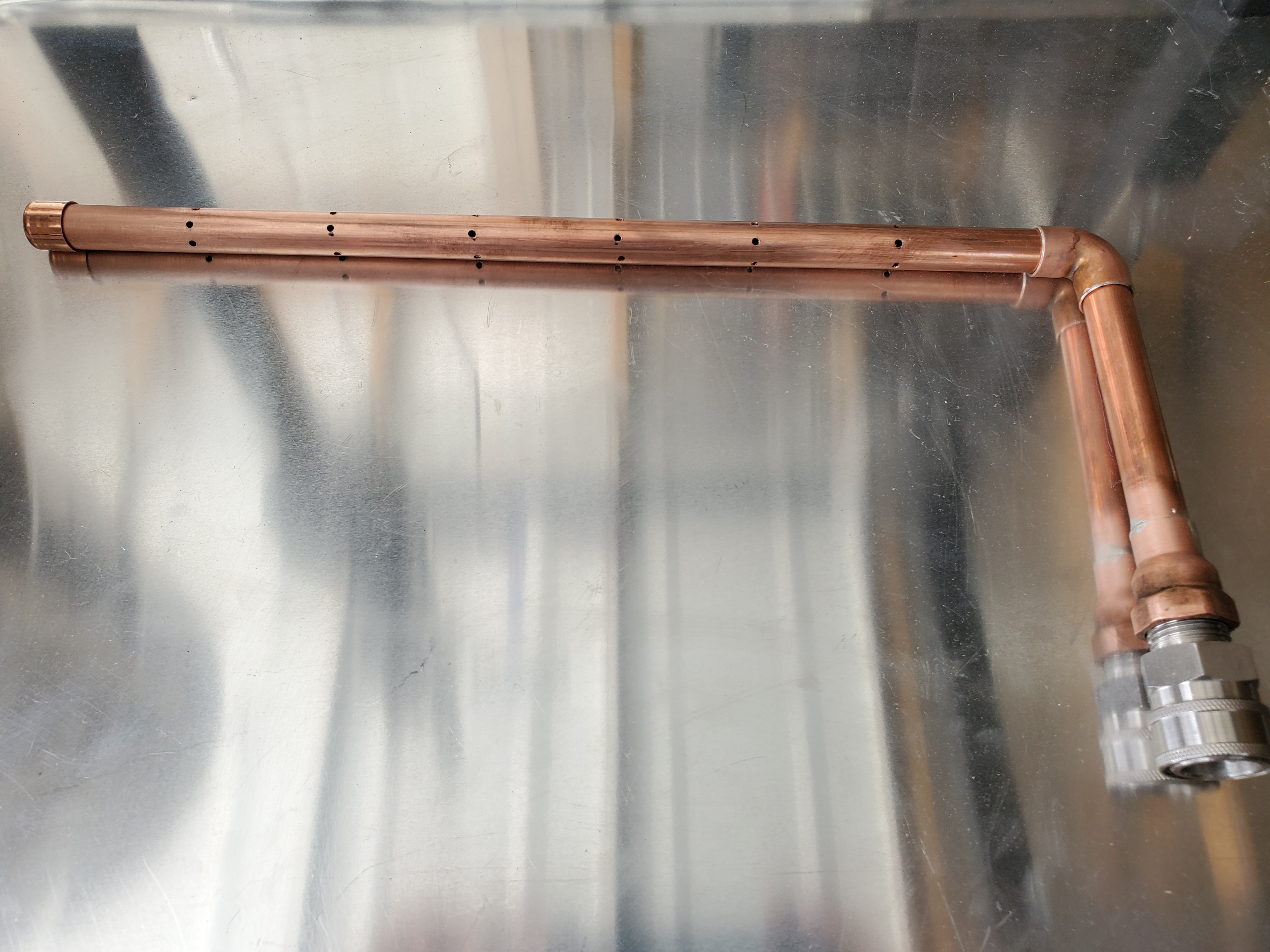

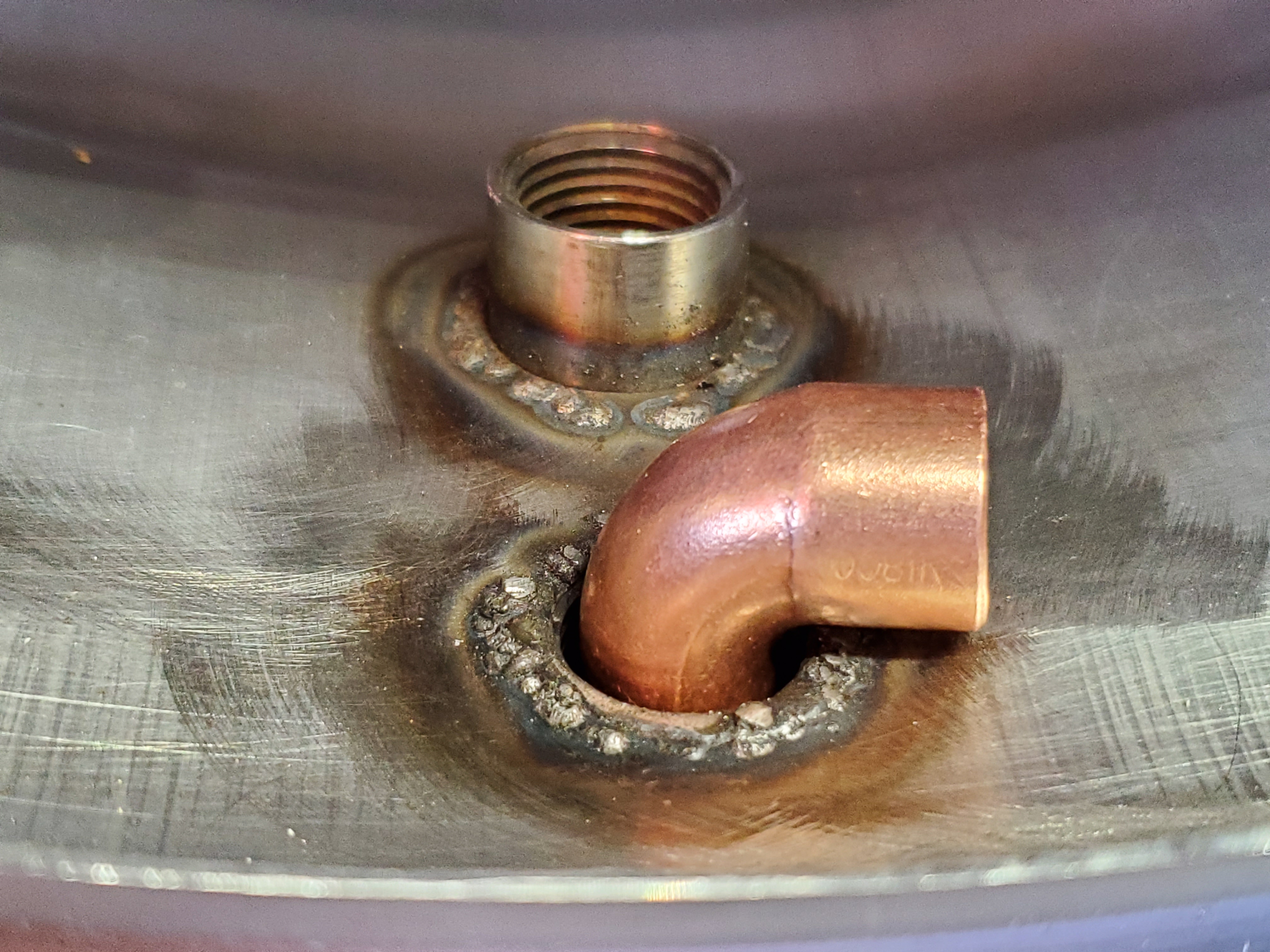

I do see tubular stainless steel elbows around on Google, but they seem to be designed for butt-welding to pipes and not for insert soldering like the copper elbow is. It would have to be insert soldering, I don't think doing a butt-weld of an elbow to the cut surface of that nipple would be worth the gymnastics inside the keg to do it.

I don't think the thermal expansion differences between copper and stainless steel will cause any cracking over time, nor would there be electro-chemical problems between the two metals either.

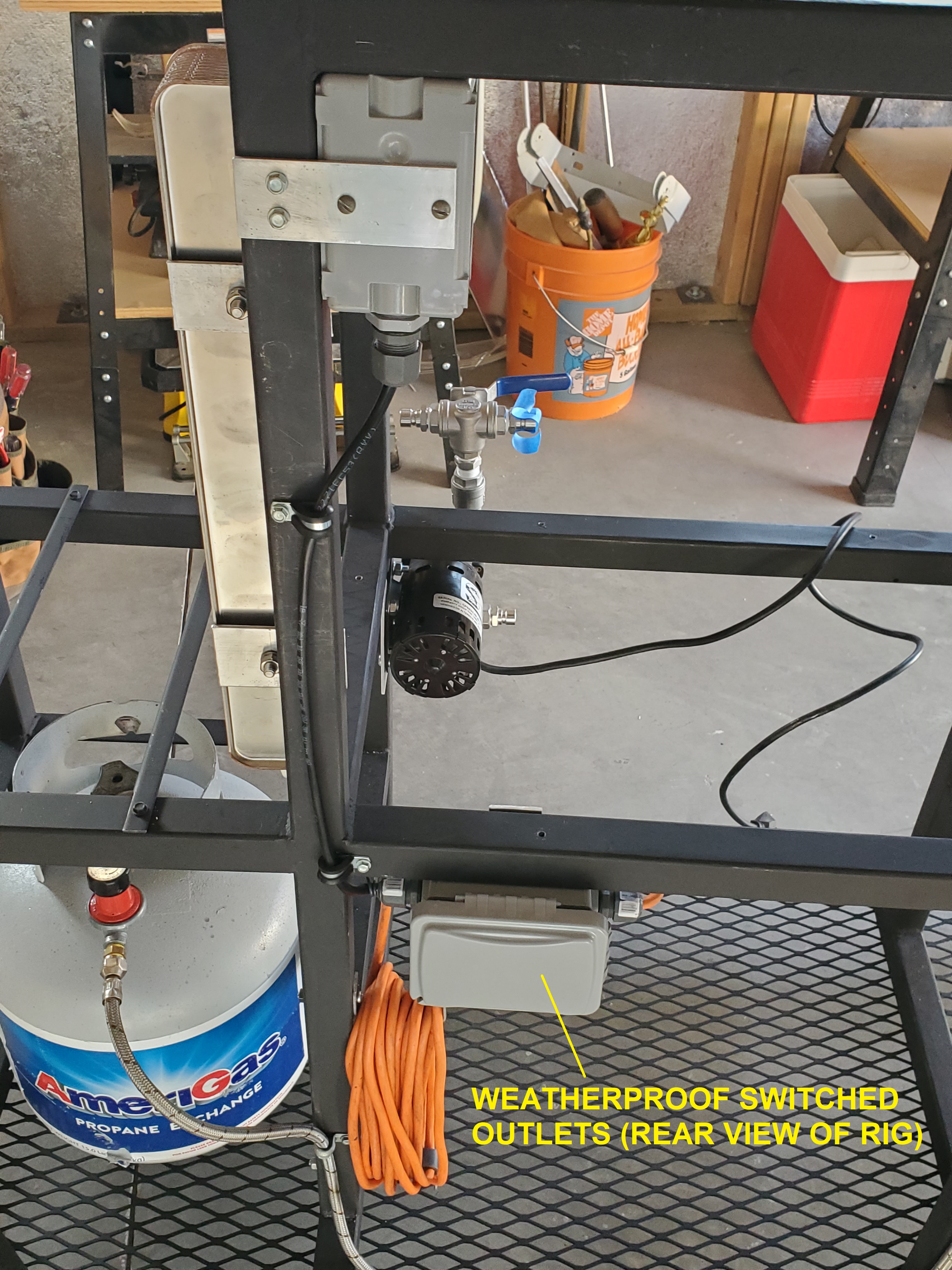

The mockups look good, really good. The pump should be low enough to prime drawing from the lower valve and venting into the keggle via the top port.

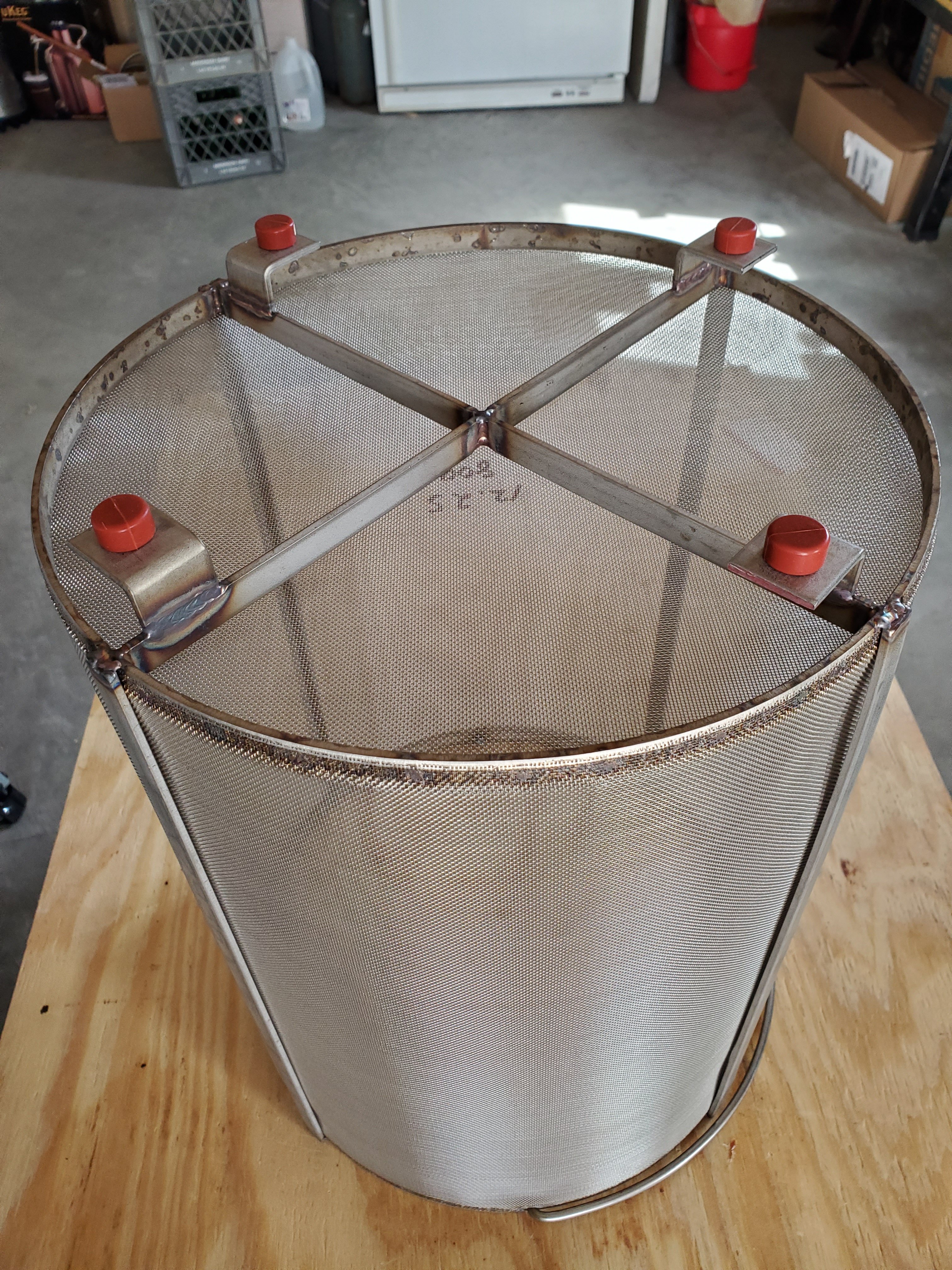

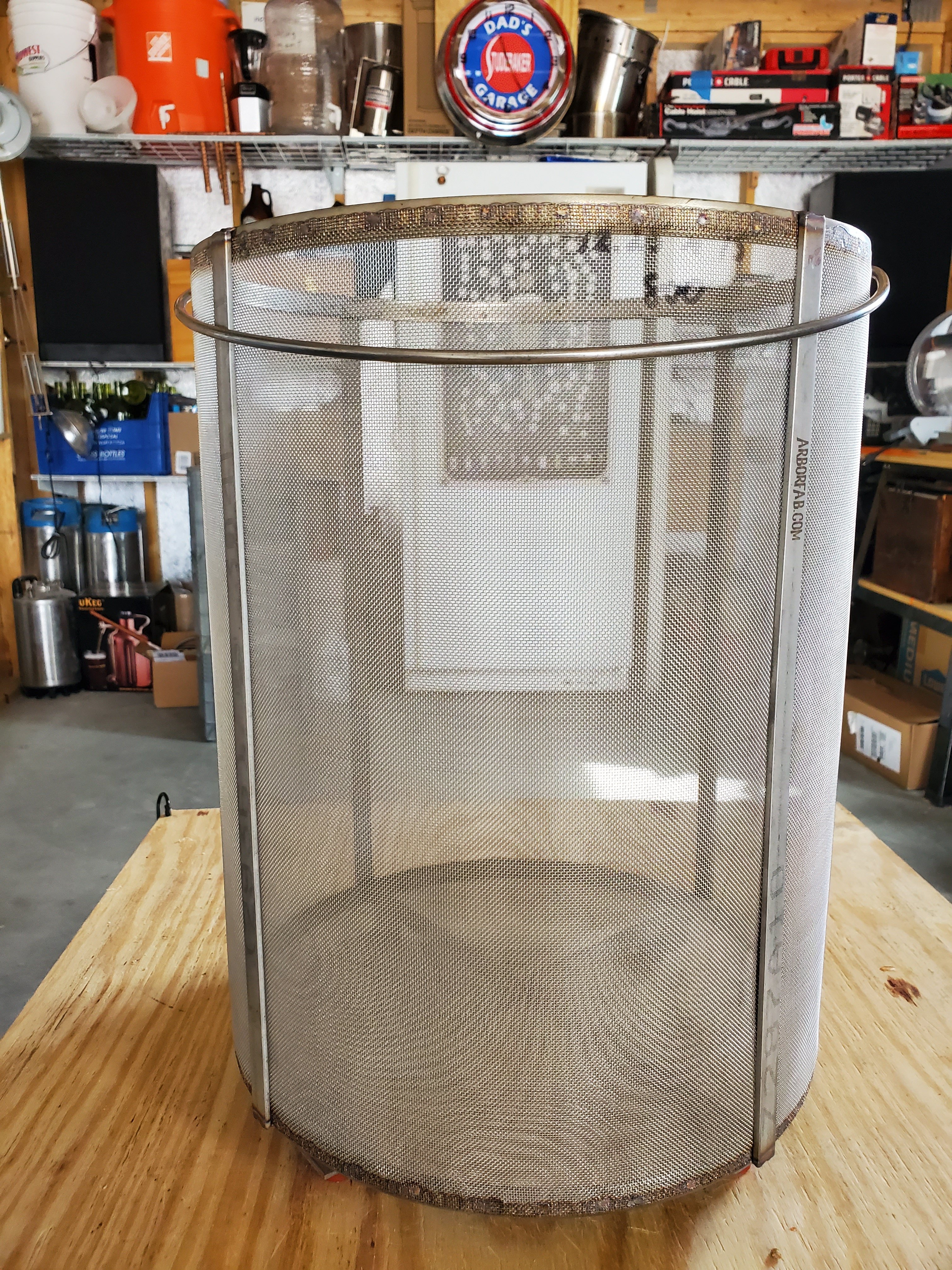

Regarding the hops and filtering, I'm a whirlpool and dump chap, if some trub gets into the fermenter, so what. I use an immersion chiller, not a plate chiller and the hops would definitely clog up the plate chiller. The pump and plumbing shouldn't have any trouble with recirculating the hops as the pellets break up into leaf fragments in most cases. You could put a bazooka screen on the intake dip tube to keep the material from ending in the plumbing in the first place.

You could also use an inline filter between the intake and the pump, or the pump and the chiller, with a 400 micron stainless steel filter in it. That would remove the recirculating requirement by using the 400 micron hop basket as a filter.

Thanks Bruce_the_Loon. I found a SS 1/2" elbow, and I have a 1/2" copper elbow also. I did a mockup of them both in a hole in the keggle wall (NOT THE NIPPLE I WILL ACTUALLY BE INSERTING THEM INTO) to show roughly how they will fit, and it turns out they are similar in "turn distance", the distance the tube travels in making the 90 degree turn. Either of these will work. I will probably drill out the entire length of the interior of the 1/2" SS nipple so the 1/2" SS elbow will just fit, and silver solder it in place. I can attach a silicone tube to that to take it the rest of the way to wherever I want it in the keggle bottom. OR, I will use copper tubing if I can find a size that will fit snugly over the 1/2" SS elbow. The 1/2" copper tube does not fit snugly over it.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)