I tried reversing the supply wires to no avail, and asked williams support. Was told it cant be reversed, that it is hard wired for their mill. Perhaps it is the wires between the switch and the motor that need to be reversed?

At any rate, the bottom mount provided a more elegant solution so it was a good problem even if only due to my cluelessness.

As the OP cleverly sorted out how to make the stock rotation work, this is really just informational for anyone else who wants to make the alteration.

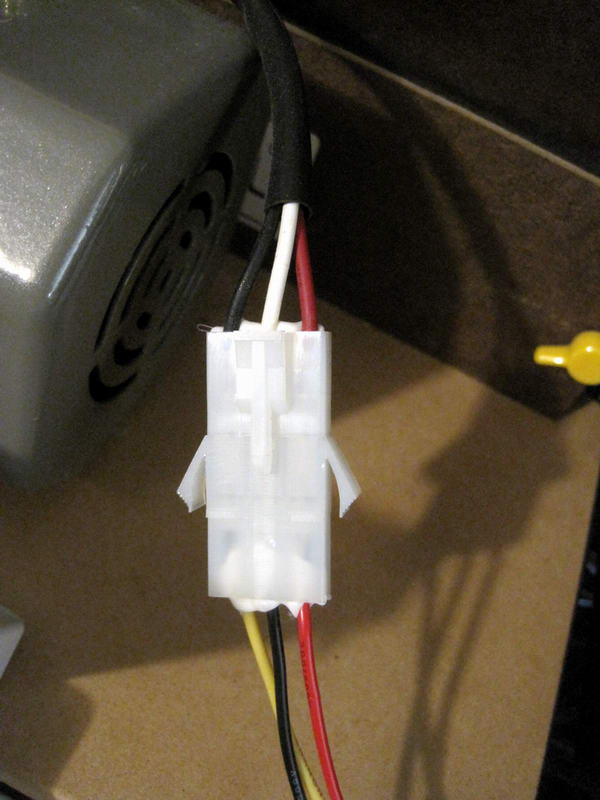

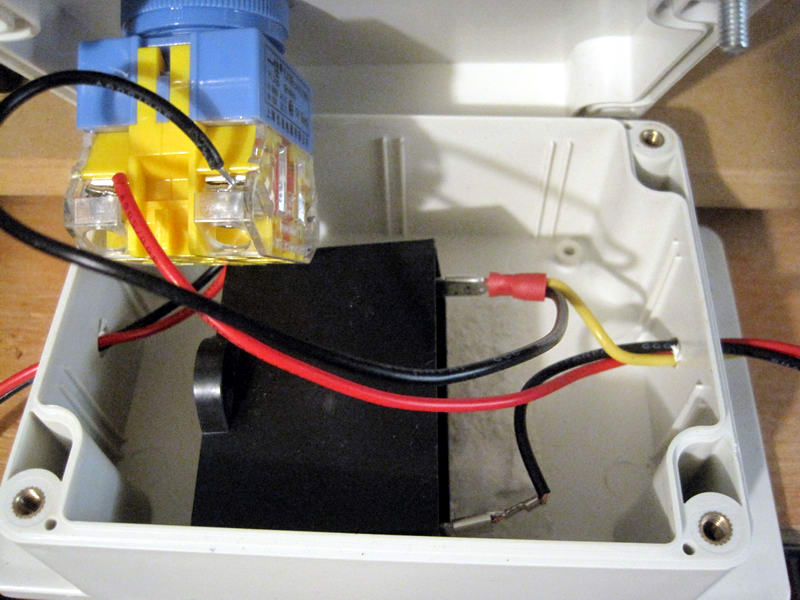

The gearmotor sold by Williams (and now MoreBeer too) does indeed reverse and seems to operate fine in either direction (don't know if there is a torque reduction for one or the other tho), however the color codes on the nameplate don't match what's inside the provided switch box as their harness changes wire colors at the coupling, which could cause some confusion. The reverse rotation change is as simple as moving the one mains line from one side of the capacitor to the other, and leaving the other connections as-is. (Red is common, Black/White is the capacitor pair)

I reset mine to run CW as such:

Those are F1 spade connectors on the cap, I had to replace one to make the new connection.

Not sure why Williams support was being difficult on this matter - perhaps they were just avoiding some perceived liability issue with the end user altering electrical components? (shrug)

I never found any detailed specs for this Kebang motor, so no idea what the torque actually provided is other than the '90 Watt' label. The output at 60Hz is ~216RPM, doing the math from nameplate 50Hz@1350 = 60Hz@1620 / 7.5 gearbox.

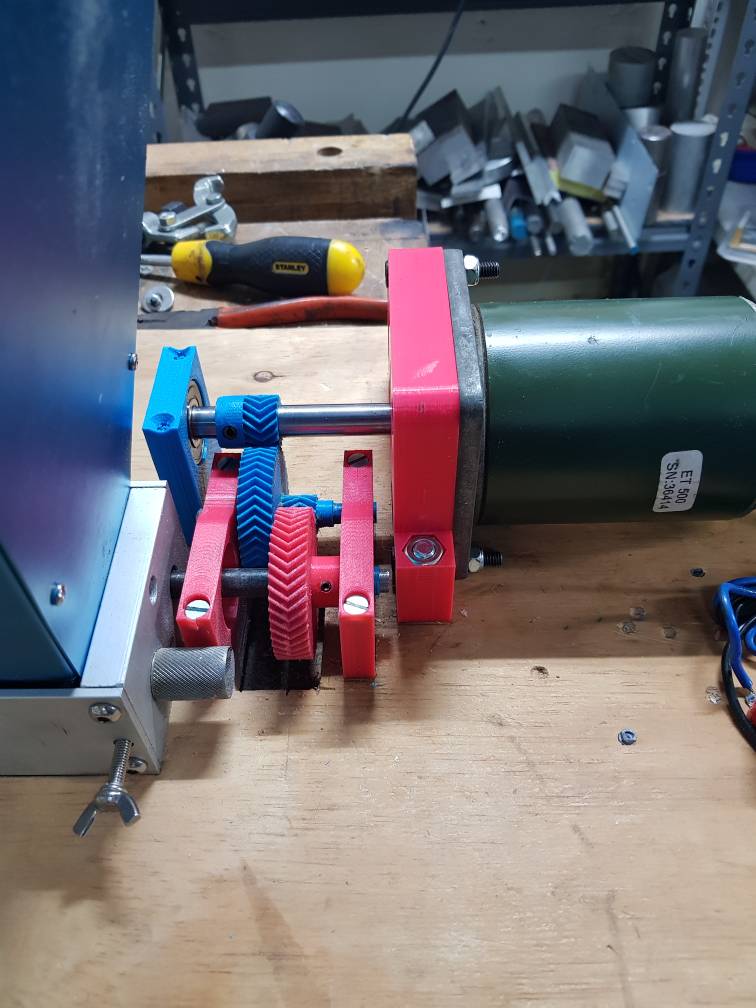

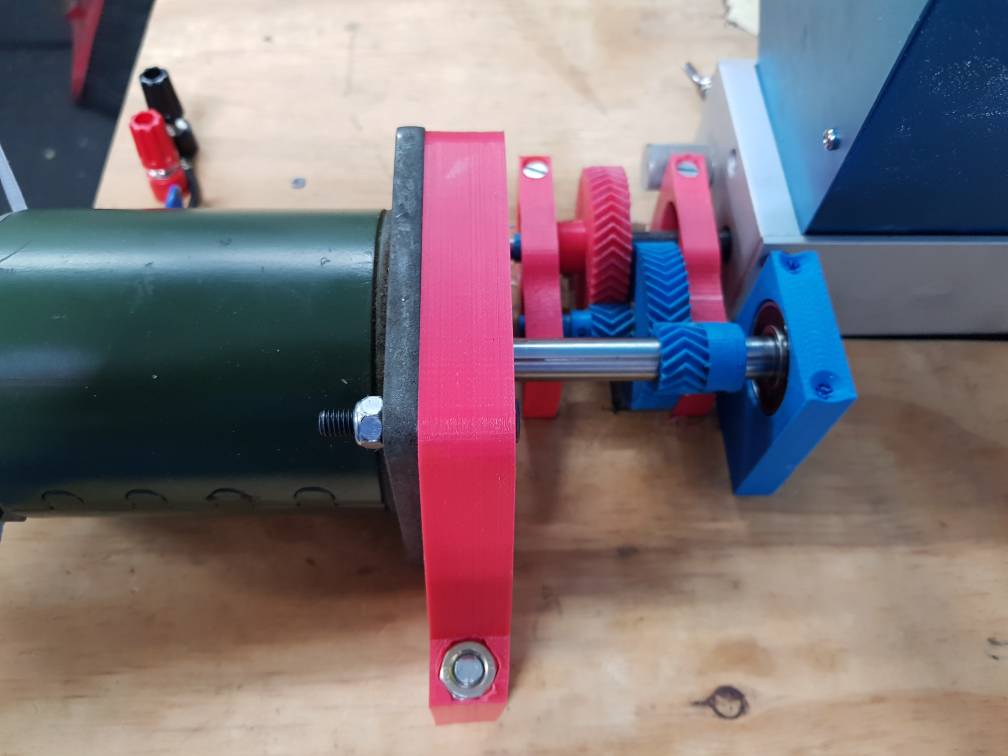

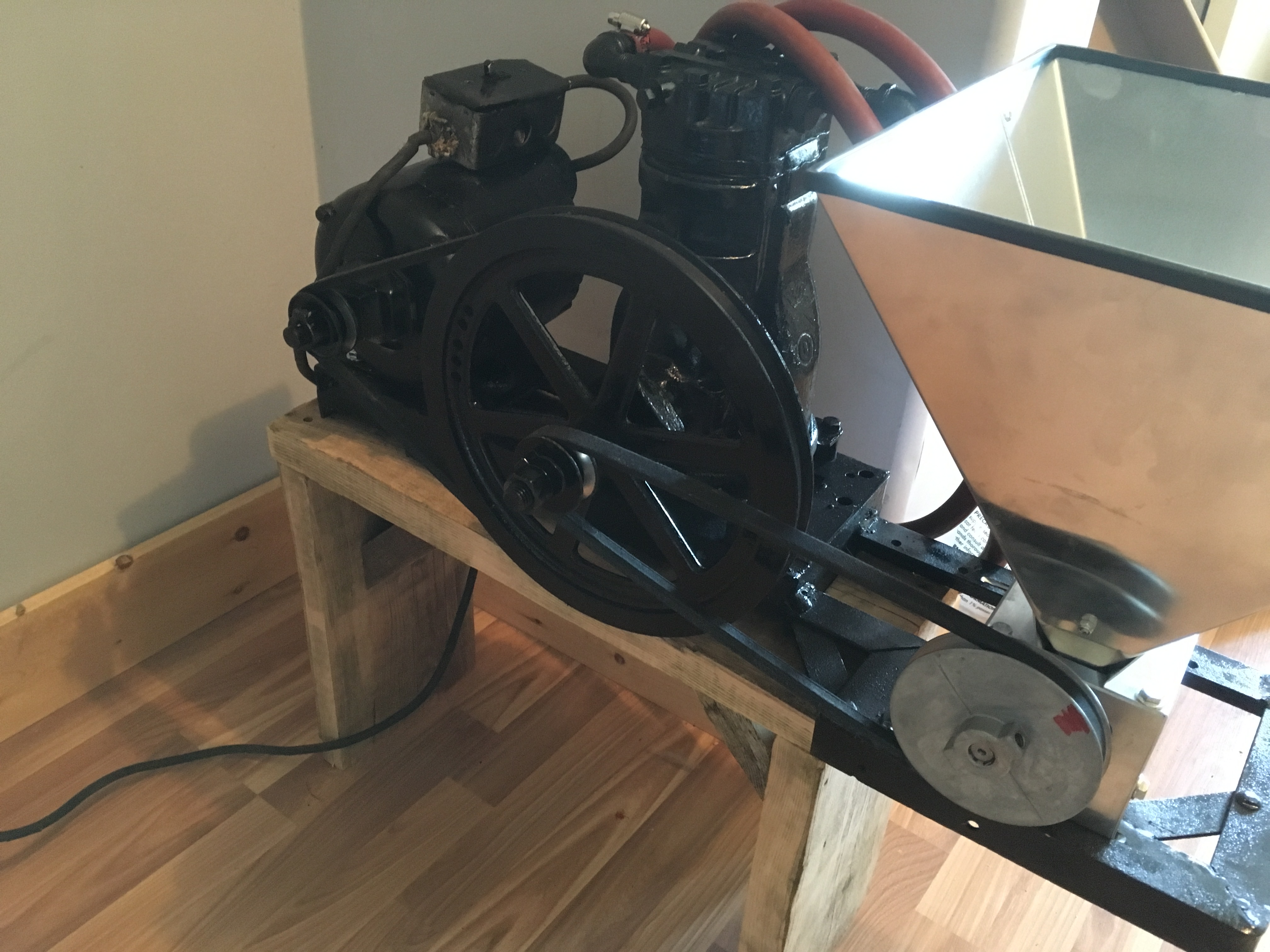

I added one of these to my JSP mill this year, though perhaps in an odd way compared to most others here:

The idea was to keep the system compact and portable by mounting to the stock base with a parallel arrangement using pulleys. (timing belt & pulleys from McMaster) The only assembly issue I ran into was this motor has a 12mm shaft and the mill is 3/8"... and timing belt pulleys don't seem to come in mixed metric/english bore sizes for a given belt type, so extra work with shims to 1/2" was required.

Works so far, no stalls or skipping so the torque must at least be adequate. Now that the motor and layout are proven to work I plan to change the base plate to a larger real wood build - the MDF flexes alarmingly when under load (pulls on the top, so has some meaningful leverage), and arrange a guard/cover.

Sadly, I found out recently that the JSP mill is no more. I was looking into one for one of the friends who taught me brewing in the first place, and Jack wrote back that his shop burned earlier this year and there there is no plan to resume production. Darn shame, as I quite like the mill with it's gear drive option.

-KD