Blazinlow86

Well-Known Member

- Joined

- Oct 19, 2016

- Messages

- 1,687

- Reaction score

- 743

I'll give it a try after dinnerThat would actually make an interesting comparison: a 50-50 wheat-barley vs. wheat only at 0.050 gap.

Brew on

I'll give it a try after dinnerThat would actually make an interesting comparison: a 50-50 wheat-barley vs. wheat only at 0.050 gap.

Brew on

If you mill your own grain, consider conditioning the grain first. If not, use rice hulls.

Recirc only needs to be about 1qt per minute.

Yes the locline is significantly better than the silicone hose method. I guarantee it. No you dont need the nozzle ring.

Tell that to the op. Clearly it does or he wouldn't have asked....

I’m having a hard time considering 85% mash efficiency anything other than superb on any system.

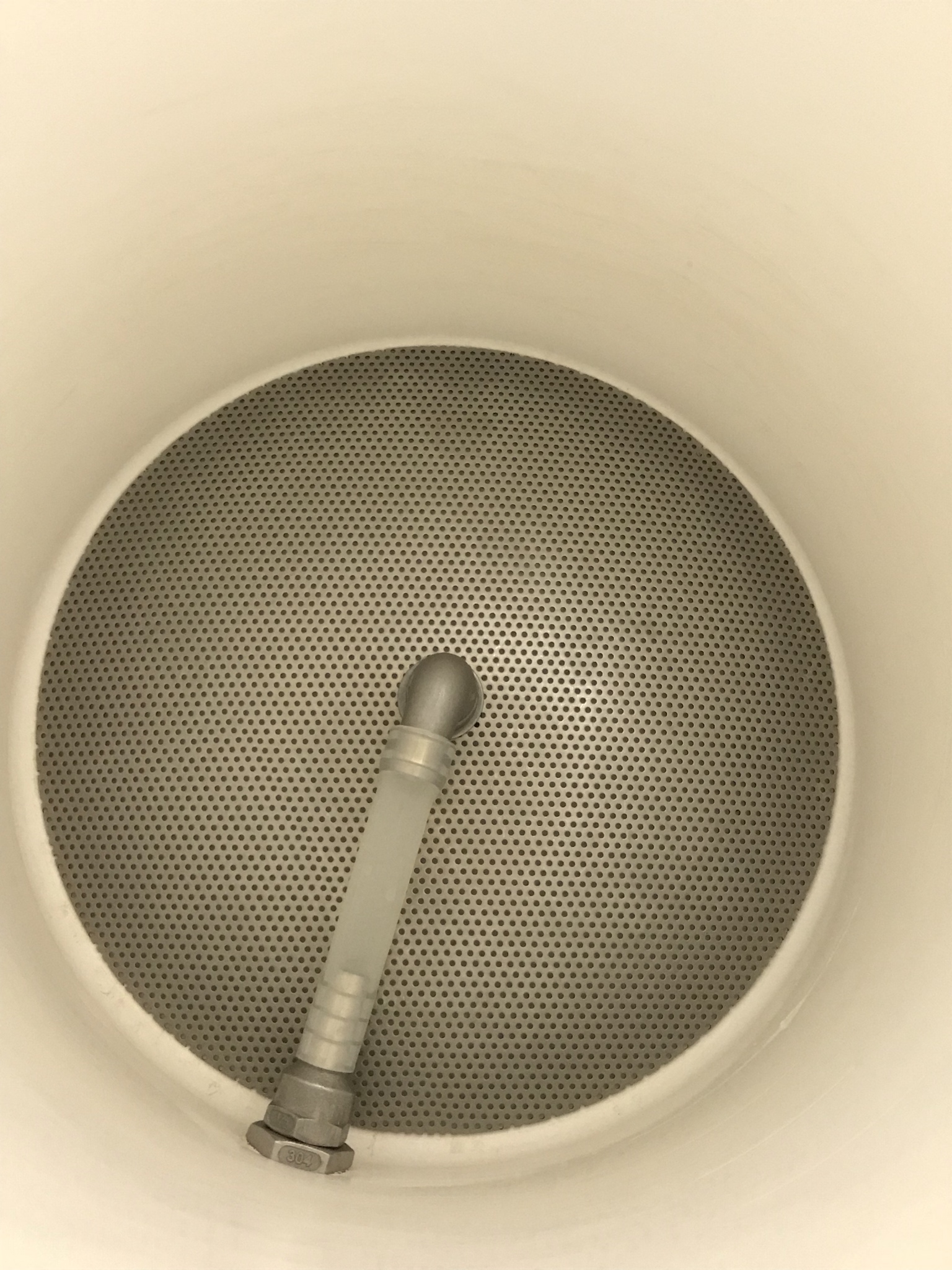

Yea the blichman false bottom is supposed to be the best. I've only ran about 40 1/2bbl batches on mine since building it but haven't had a issue with a stuck/ slow sparge since the first time. I normally mash in adjust ph and do chores or head out for errands. Cheers

Looking through some past several beers, Beersmith reports my mash efficiency between 76% and 106%.

Frankly, I've never paid much attention to it. Focusing on Brewhouse efficiency as a constant (in my case 78%) takes into account all losses from my system, so dialing that in gives me consistent and accurate target numbers.

your brewhouse efficiency is always 78%, regardless of OG and amount of hops used, etc. (assuming you are referring to brewhouse efficiency as the efficiency all the way through to the fermenter.)? That seems really weird to me. A hoppy barleywine would have a much lower lauter, overall, brewhouse, whatever for me than a hopless light lager (actually, the conversion efficiency could be as good or better but that is the only one.)

Sorry... typed to fast and wasn't clear.

Brewhouse efficiency is the only "efficiency" in Beersmith that is inputted. Several batches and measurement losses to kettle, trub, hoses, etc. has determined (for my system) BE is entered at 78%.

This has consistently brought me to target numbers regardless of beer style, heavy or light.

For that reason (and I may be the outlier here) I really don't pay much attention to measured BE or ME as it varies depending on what you're brewing and therefore doesn't provide me any meaningful data.

I also wonder about the false bottom. It sounds like I have the same one as you and I noticed when I attempted to do a full volume mash with 11-12lb's of grain, I think the false bottom flexed and it stopped flow all together. I may cut a section of 1.5" stainless pipe to add support if I choose to do that again.

Doesn't seem completely plausible to me that the BH efficiency can be constant no matter what the OG of the beer.

BrewHouse Eff = Conv Eff * Lauter Eff * Fermenter Vol / Post-Boil BK VolThe above applies whenever no sugar is added during the boil. For a constant pre-boil batch size the lauter efficiency has to go down as the grain bill weight increases (it's just physical chemistry.) Conversion efficiency can be independent of grain bill weight. So to maintain constant BH efficiency efficiency as grain bill increases, you either have to increase the pre-boil volume (and boil off the excess water), or take larger transfer losses (post-boil to fermenter volume losses) on smaller beers. Just can't be any other way. Can anyone find a flaw in this reasoning?

Ok, I think I understand what you are saying now.There's no flaw in your reasoning..

My BHE is "set" at 78% based on my system losses. However measured efficiency varies between brew styles.

Perhaps it a Beersmith thing.

I run mine at 1.5 to 2 gpm (i have a cheap flow meter inline which shows flow rate) no issues with a 20 dollar 24v dc pump and I get over 90% efficiency this way... I think most people make more headches for themselves trying to push the flow rate higher which gives zero benfit and many possible problems.. one reason is the 5-7 gallon per minute home brewing pumps are just too big for this and have to be throttled way down. think about it... theres what maybe 7-8 gallons or mash liquid in the MT for an 11 gallon brew? at 1.5gpm the mash is getting fully recycled through about every 5 mins.. the mash temp isnt going to drop much in 5 mins if at all. also the chance of channeling is pretty much eliminated as well as clogging the false bottom.Interesting. I’m reading more and more that a lot of people don’t run their mash recirculation full bore (like I thought I was supposed to).

Do you stir your mash ocassionally or no? I’ve heard both yes and no. I didn’t have a choice with this last bath and had to stir multiple times and reset the grainbed.

Tell me about your cheap flow meter. For sake of consistency, I'd love to pick one up.I run mine at 1.5 to 2 gpm (i have a cheap flow meter inline which shows flow rate) no issues with a 20 dollar 24v dc pump and I get over 90% efficiency this way... I think most people make more headches for themselves trying to push the flow rate higher which gives zero benfit and many possible problems.. one reason is the 5-7 gallon per minute home brewing pumps are just too big for this and have to be throttled way down.

btw I never stir may mash once recirc starts.

those pumps are sold for all sorts of industrial applications as well . We use them in the machines I service (only they are marked up many times that cost with someone elses name on them) . nothing wrong with them... like I said no need for all that flow for our size brewing systems really.Tell me about your cheap flow meter. For sake of consistency, I'd love to pick one up.

I have a pair of "china chugger" pumps (https://www.aliexpress.com/item/Hig...417.html?spm=a2g0s.9042311.0.0.2ad24c4dZMhWHY) which are rated at 4-5gpm because I felt like the chuggers cost twice the price and not necessarily worth the extra 2gpm. I love my pumps. Cheap and work well.

Rated to 150 degrees. :-/ I'm sure it would be fine, but pumping hot wort through that could be problematic.

Not sure if its been mentioned but I have run an e-herms system for over 2 years now (and I crush a bit finer) and my solution to this was is to bump up my water to grist ratio. I used to run 1.25qt/lb grain and struggled with the recirc much as you are but have moved to 1.4qt/lb grain and my recirc is wide open, no problems.

My brewhouse efficiency sits around 80% which is not bad at all.

The hose floating deal is not too big of a deal, you just dont want it jammed into the grain bed..Mine sits right below the water line most of the time.

It's not pumping too fast your grainbed isnt flowing enough to keep up..... Don't overthink it. Not saying people aren't successfully making great beer throttling back there pumps but why settle for that if you don't have to. Mill looser next time and use rice hulls also if your using wheat. The whole reason I built my eherms system was not have to screw around with thing like stuck mash/sparge. It's supposed to be consistant and reliableI've always run 1.75 qt/lb (including on the day of my first HERMS batch), but as the rest of the community has stated, with the wheat/oats in my grain bill, I was clearly just pumping too fast. I could see air pockets forming in the mash out/pump feed hose. I already have a decent false bottom with high flow plumbing, so I'm going to try pumping slower next batch see how things go.

Or...is the grainbed not flowing enough because it compacted as a result of pumping too fast? I’m quite convinced that’s what happened for me.It's not pumping too fast your grainbed isnt flowing enough to keep up..... Don't overthink it. Not saying people aren't successfully making great beer throttling back there pumps but why settle for that if you don't have to. Mill looser next time and use rice hulls also if your using wheat. The whole reason I built my eherms system was not have to screw around with thing like stuck mash/sparge. It's supposed to be consistant and reliable