This is how started doing step mashes over single infusion. - Heat Loss -

I adopted LOB and found out my 12 gallon igloo mash tun cooler was too big for holding heat on smaller grain bills. So adding frequent boiling water additions compensated for the heat loss. Doing this had me pretty much going to a no-sparge situation, but with high mash efficiency over 90%. Sometimes over 95%. A lot of that is just from mashing longer. See the times below and the blog link.

One other complexity was I wanted to top out at 7 gallons of mash/sparge water so I would start my boil typically with 5.75 gallons. I didn't want long boil offs after long mashing.

Anyhow I like this blog. Its a good read. It helped me fix my heat loss problem.

http://counterbrew.blogspot.com/2016/10/a-beer-geek-guide-to-step-mashing-even.html

I typically do the following mashes with boiling water additions. Works great. However it will be better/more fun with my new RIM/HERMS Set-up. (just got it plumbed up last week) Using this my mash efficiency is very high, in the 90s, but they are long mashes. I also pay attention to the pH with my brewing water. Mashing is the part I like most about brewing.

I use these two most frequently.

1) Dry Beer

2) Max phenolic expression.

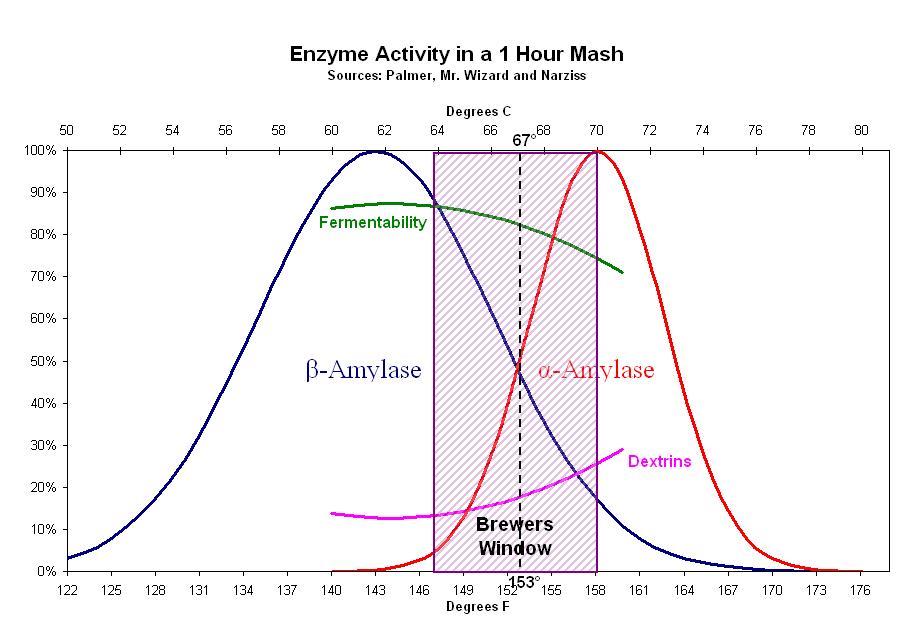

I have this graphic on my step mashing calculator within sheets.

A Step Mash for clarity and body.

100 F for 20 minutes

134 F for 20 minutes

145 F for 30 minutes

155 F for 20 minutes

168 F for 10 minutes

A Step Mash for maximum phenolic expression.

100 F for 20 minutes

113 F for 35 minutes

134 F for 10 minutes

150 F for 30 minutes

168 F for 10 minutes

A simple step mash for maximum extraction of sugar

100 F for 20 minutes

150 F for 45 minutes

168 F for 10 minutes

Step mash for dry beer - dry stout & dry lager like ales

145 F for 30 minutes

152 F for 50 minutes

158 F for 30 minutes

168 F for 10 minutes

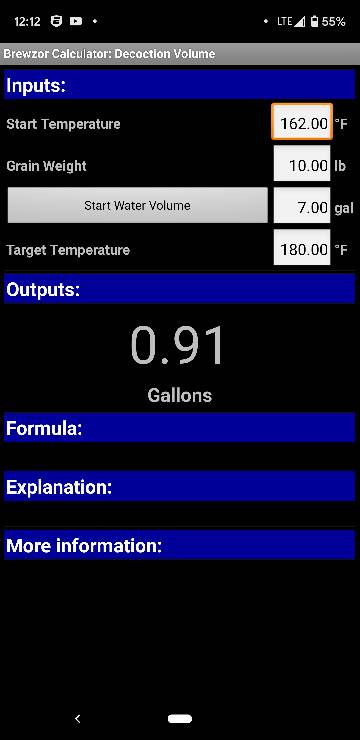

This really works well if you account for the temp loss between steps. John Palmer's equation on step mashing allows for the heat loss adjustment. It's in the 2nd page. I also pasted it below.

Use this formula in a spreadsheet if you don't have a step calculator that you like using.

http://howtobrew.com/book/section-3/the-methods-of-mashing/multi-rest-mashing

"Initial Infusion Equation:

Strike Water Temperature Tw = (.2/r)(T2 - T1) + T2

Mash Infusion Equation:

Wa = (T2 - T1)(.2G + Wm)/(Tw - T2)

where:

r = The ratio of water to grain in quarts per pound.

Wa = The amount of boiling water added (in quarts).

Wm = The total amount of water in the mash (in quarts).

T1 = The initial temperature of the mash.

T2 = The target temperature of the mash.

Tw = The actual temperature of the infusion water.

G = The amount of grain in the mash (in pounds).

"The infusion water does not have to be boiling, a common choice is to use the sparge water at 170¡F. Then TB becomes 170 ¡F and more water (Wa) will be needed to make up the additional quantity of heat."

I typically underlet with bottom to bottom connections HLT to MLT. I use a yardstick that I convert gallons/qrts to inches in the kettle. Its pretty easy to do if you just crack the HLT valve slowly let it transfer until you see the required drop in inches in the HLT.

Cheers!!!

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)