@bajaedition, I apologize if my post came across as obstinate, or otherwise unhelpful. It wasn't my intent. Sometimes the best thing to do is learn from a mistake and move on, which is what I was suggesting.

Not only have I heard of amylase enzyme, I actually mentioned the possibility of buying it in my post...

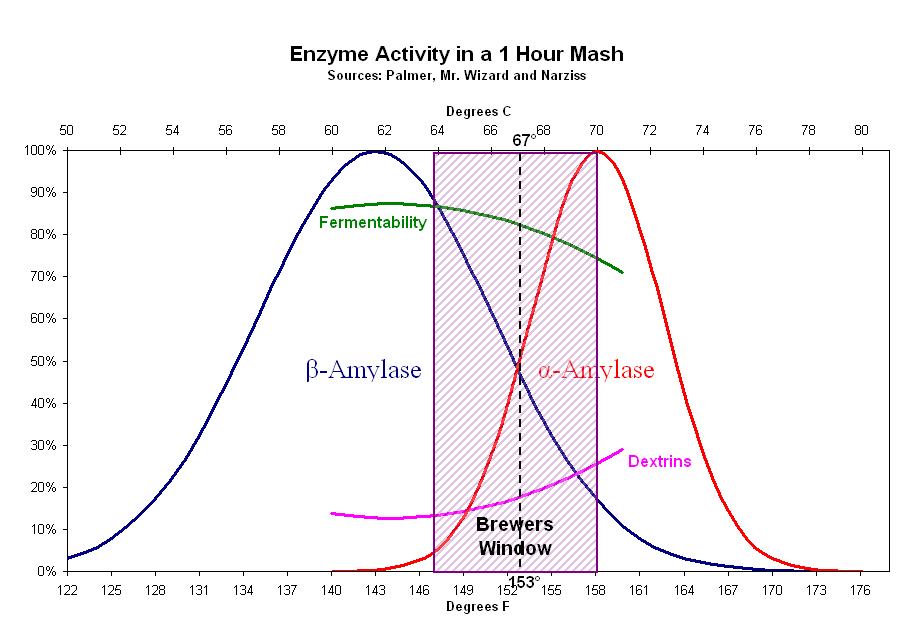

120 F is at the very very bottom of the temperature band for beta amylase. It's completely outside the band for alpha amylase. Even in the "optimum" temperature range, beta amylase works more slowly than alpha amylase. In other words, you are technically correct. You will get "some" conversion at 120 F, but certainly not what you'd hoped to achieve when you set out to hit a conversion temperature between 145 and 158...

I have no doubt that the OP could get his batch of wort to "convert" by raising it to 150 and adding in liquid enzymes. Keep in mind, though, this is being done on finished wort. i.e. it's been boiled, hopped, aerated, and pitched.

If the OP decides to give it a try (and I'd be the last to knock him for doing so) I think most would counsel going through a full boil again to sterilize before pitching more yeast. I'll readily admit, I have no idea what that's going to do to bitterness levels. I'd suspect that at the very least you'll drive off any flavor and aroma components and need to add more late hops to make them up. It'll probably also effect underlying IBU's.

So... Yes. You could do all of this, and I'd commend your spirit for doing so. You won't, however, likely end up with the beer you started out trying to brew, and you're going to do a lot of work getting here.

It's your choice.

If it were me, I'd raise a mournful toast to the beer gods, spend a moment in quiet contemplation, and dump the batch.

Edit: You're also right that, on re-reading, I've made an assumption that this is finished wort. If for some reason the OP didn't go through the boil yet, then raising to 150 and adding liquid enzymes is a great idea.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)