- Joined

- Jul 22, 2021

- Messages

- 884

- Reaction score

- 1,478

Today I started my newest Pinot Noir pyment. This will be my first using a grape must instead of a wine kit that I hydrate from a concentrate. Prior to today I've done a lot of crash course reading on Pinot Noir which I hope helps.

The grapes arrives "semi-frozen", which I believe means that they come out of frozen storage and then are shipped. These came from Wine Grapes Direct and were harvested in 2022 in Willamette Valley, OR. They went straight to my garage refrigerator when they arrived and the next day I checked pH, SG and SO2 levels. The crushed and se-stemmed must came with 20 PPM of SO2 which I increased to 40 PPM as there is sure to be wild yeast and other things from the Vineyard in there.

The Grape must came in at a pH of 3.6 and a SG 1.096; so about 12.5% ABV on its own. The grape must is 4.25 gallons. Pectic enzyme was added after raising up the free SO2 levels and then it went back into the refrigerator for a 3 day cold soak to increase the color and tannic extraction.

My fermenter will handle a total volume of 7.76 gallons, so I decided a 6.5 gallon total must would be good for leaving enough headroom for the grape cap; I'll find out soon enough if that is enough headroom.

With my total volume decided i knew that I had to come up with 2.25 gallon honey must that would exceed the grape sugars, as my mind says that I need more sugars from honey to make it a pyment. So I needed to have a blended SG that exceeded the 1.096 SG.

My honey must is 2.25 gallons @ 1.128 SG which blended with the grape must would give me the 6.5 gallons at a blended SG of 1.107 and have a potential of 14% ABV. The actual OG ended up at 1.112 giving a potential 14.7%... a bit higher than I was intending, but there it is as I didn't want to increase the volume by adding water to reduce the gravity.

As the grapes were refrigerator temperature for the "cold soak", you want to try and rapidly increase the grape must temperature to a fermentable temperature to not provide time for the growth of Kloeckera yeast that can be typical on grapes brought in from the field. That yeast strain can provide vinegar-ish flavors if left to grow. That was the main reason I increased SO2 levels in the must when I added pectic enzyme. As I am not ready for my temperature control, I started with my honey must and heated 2 gallons of spring water to about 140F and added to the fermenter with my honey. The colder grape must was added to that warmer honey must and my combined must was about 65F.

While I was messing with the different musts, I had 15g of Lalvin RC-212 on a heated stir plate going with Go-Ferm Sterol Flash that I slowly inoculated with honey must and later on with grape must and eventually the blended must to get the yeast starter within 10F of the must temp.

The final blended must received some different yeast adjunct, a little red tannin, and 2 minutes of pure O2 through a .5 micron stone and then the large yeast starter was pitched. A short while later I added 1g of DAP and tomorrow will start on a TOSNA protocol. Fermentation is under way nicely and tomorrow will start grape cap punch down and nutrient adds.

I hope this goes well. Sanitation has been extreme and attention to details has been top of my game along with a variety of equipment purchases to hopefully take this up a notch. My biggest doubt is related to this being the first time using a raw grape must, but it will be easier the next time. The most notable equipment add lets me check actual SO2 levels instead of approximating.

Edit: Adding some pictures of the must which is so different than what I am used to with my prior meads.

The grapes arrives "semi-frozen", which I believe means that they come out of frozen storage and then are shipped. These came from Wine Grapes Direct and were harvested in 2022 in Willamette Valley, OR. They went straight to my garage refrigerator when they arrived and the next day I checked pH, SG and SO2 levels. The crushed and se-stemmed must came with 20 PPM of SO2 which I increased to 40 PPM as there is sure to be wild yeast and other things from the Vineyard in there.

The Grape must came in at a pH of 3.6 and a SG 1.096; so about 12.5% ABV on its own. The grape must is 4.25 gallons. Pectic enzyme was added after raising up the free SO2 levels and then it went back into the refrigerator for a 3 day cold soak to increase the color and tannic extraction.

My fermenter will handle a total volume of 7.76 gallons, so I decided a 6.5 gallon total must would be good for leaving enough headroom for the grape cap; I'll find out soon enough if that is enough headroom.

With my total volume decided i knew that I had to come up with 2.25 gallon honey must that would exceed the grape sugars, as my mind says that I need more sugars from honey to make it a pyment. So I needed to have a blended SG that exceeded the 1.096 SG.

My honey must is 2.25 gallons @ 1.128 SG which blended with the grape must would give me the 6.5 gallons at a blended SG of 1.107 and have a potential of 14% ABV. The actual OG ended up at 1.112 giving a potential 14.7%... a bit higher than I was intending, but there it is as I didn't want to increase the volume by adding water to reduce the gravity.

As the grapes were refrigerator temperature for the "cold soak", you want to try and rapidly increase the grape must temperature to a fermentable temperature to not provide time for the growth of Kloeckera yeast that can be typical on grapes brought in from the field. That yeast strain can provide vinegar-ish flavors if left to grow. That was the main reason I increased SO2 levels in the must when I added pectic enzyme. As I am not ready for my temperature control, I started with my honey must and heated 2 gallons of spring water to about 140F and added to the fermenter with my honey. The colder grape must was added to that warmer honey must and my combined must was about 65F.

While I was messing with the different musts, I had 15g of Lalvin RC-212 on a heated stir plate going with Go-Ferm Sterol Flash that I slowly inoculated with honey must and later on with grape must and eventually the blended must to get the yeast starter within 10F of the must temp.

The final blended must received some different yeast adjunct, a little red tannin, and 2 minutes of pure O2 through a .5 micron stone and then the large yeast starter was pitched. A short while later I added 1g of DAP and tomorrow will start on a TOSNA protocol. Fermentation is under way nicely and tomorrow will start grape cap punch down and nutrient adds.

I hope this goes well. Sanitation has been extreme and attention to details has been top of my game along with a variety of equipment purchases to hopefully take this up a notch. My biggest doubt is related to this being the first time using a raw grape must, but it will be easier the next time. The most notable equipment add lets me check actual SO2 levels instead of approximating.

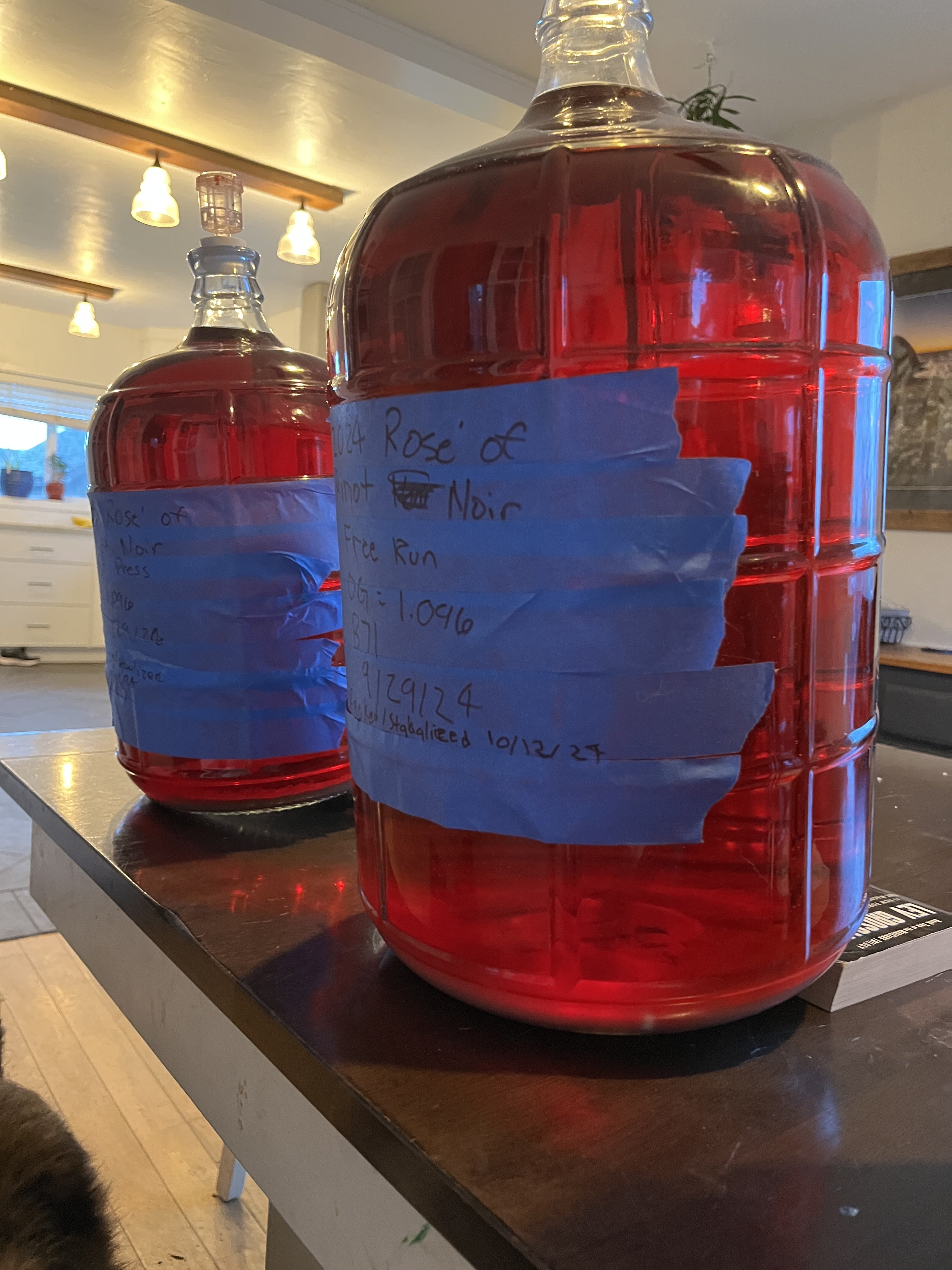

Edit: Adding some pictures of the must which is so different than what I am used to with my prior meads.

Attachments

Last edited:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)