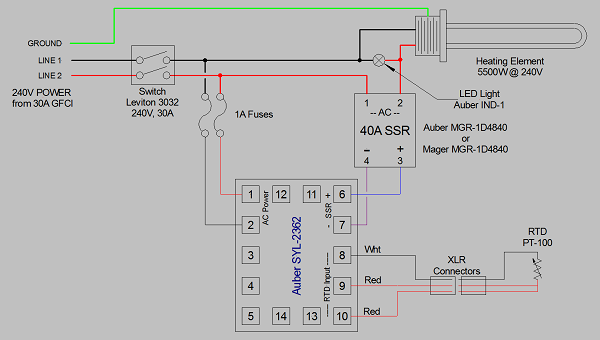

thanks everyone... now, the next question...using the diagram I posted above... will this SSR be wired just like it looks in the diagram? It doesn't have the "1-2-3-4" but instead has "L1-L2-T1-T2"...

NO. This is a dual SSR (two SSR's in one package.) The screw terminals are all AC power connections. The left side is for one SSR, and the right side for the other. The DC control signals go to the pins near the bottom center (above the mounting hole.) I don't know which pins control which SSR, or which are plus or minus. It may be marked on the body somewhere (like the AC connections are), or you may have to look for the information on the interwebs.

Edit: Looking harder at the pic, the control signal pins are marked (just above the pins.)

Brew on

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)