Many, MANY thanks to all who have contributed so much to this thread (and others), and certainly a very special shout-out to P-J!! And hey, Kal, my retirement savings and my daughter's college fund still all HATE you!

I've read all 65 pages, and I got more than a little excited on page 45 (#449) where Hunky asked something that was pretty close to my question, but by the next page he appeared to go another direction. Obviously from the length of this thread, there are hundreds of permutations in how to wire up a control panel, so here's mine.

I have three 20-gallon kettles and I brew 10 gallon batches. I'd like to be able to brew back-to-back on the weekends my SWMBO lets me have my man-card back, if not back-to-back-to-back, so I will certainly need to run both the HLT and BK heater elements simultaneously, as well as the element in the RIMS.

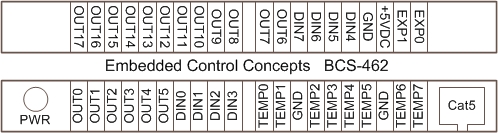

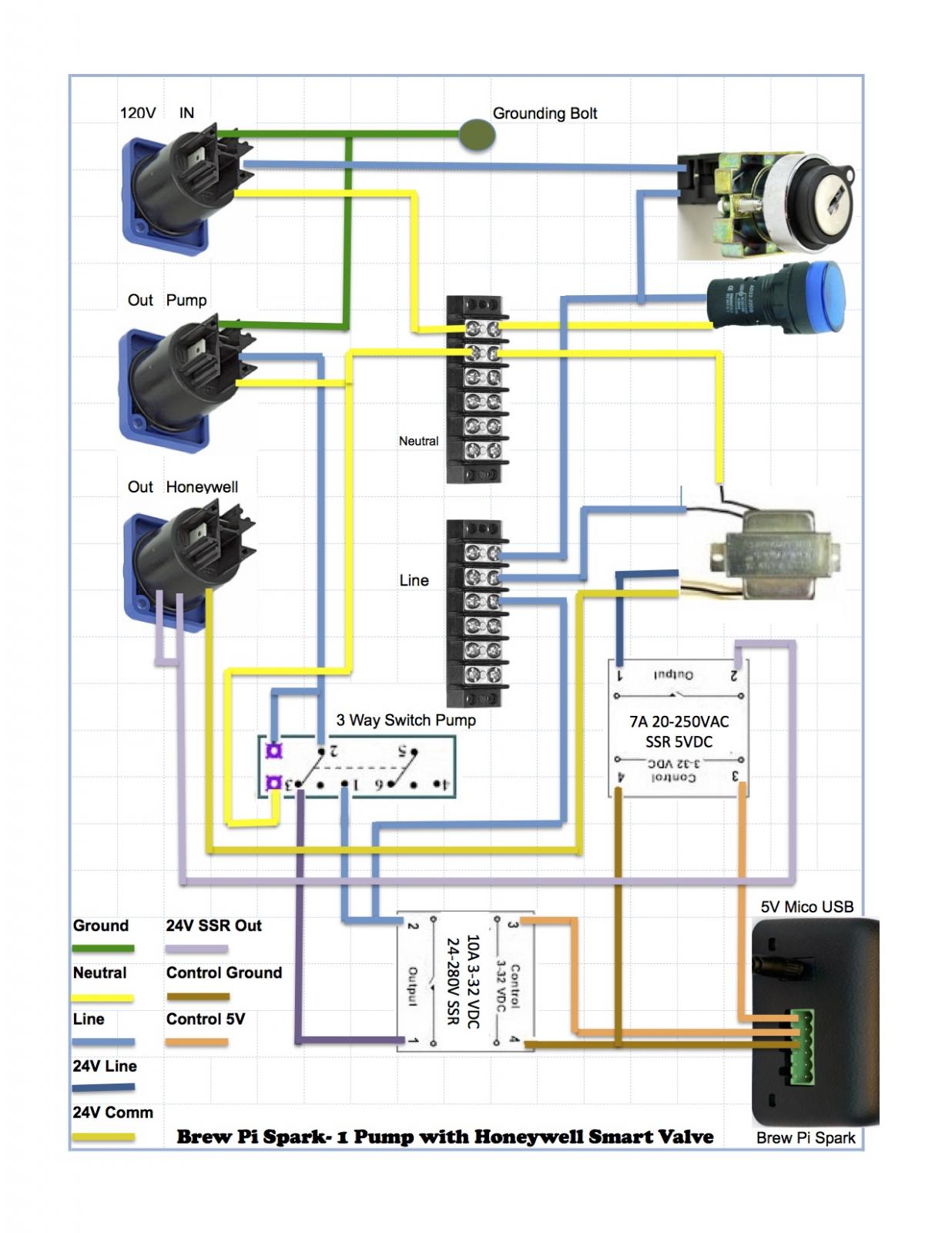

I need a panel that brings in 2 each 30A/240V circuits to independently power the HLT and BK Blichmann BoilCoils (5000W/240V), and 2 each 20A/120V circuits, one to power a BCS-462 (differing from the BCS-460 only in the number of inputs [2X] and outputs [3X]), three March pumps, and the 5VDC and 12VDC transformers to power the valves, lights, relay boards; and the other circuit dedicated to powering just the RIMS (2000W/120V). The electrical outlets have already been pulled to the brew area in the garage (one is just the 20A/120V circuit that services the entire garage, and will power the BCS/pumps). The others are GFCI-protected circuits pulled from the main panel by a licensed electrician.

I was going to use several of P-J's electrical drawings, and just treat my system as if I had three simple one-element systems, with the BCS-462 substituted in for the PIDs. Besides needing more space for all the electrical components, I think it's pretty straight-forward - again, thanks to P-J!!

One of my concerns is the e-stop, as that might get a little tricky - I don't want to have to hit three of them, so maybe something in parallel? Thoughts?

More importantly, is there something I'm missing in combining all of this together?? I think the SSRs and contactors are going to keep all the electrons in their respective cages, and the BCS-462 behind them doesn't really care where all the power is coming from, right?

Finally, how did the collective effort to get P-J's computer upgraded to the 21st Century go? I have a few $$$ burning a hole in my pocket, and I'd love to contribute!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)