Now, of course I don't have the recipe on me but I wanted to start this thread nonetheless. Bear with me and I'll get that part up ASAP.

For now, the ingredients as I remember them were:

10 lbs Domestic 2 Row

1 lb flaked barley

.75 lb roasted barley

.25 lb chocolate row

.5 oz Target (?) hops, for which I substituted the Fuggle my LHBS had for the similar profile.

English Pale Ale Yeast (not sure of any more specifics)

1 sheet cake, baked, crumbled, boiled, simmered as slurry for 15 minutes, chilled and scrapped for fat.

Grain gets mashed for 60 at 154F and cake slurry goes into the mash before boil. Hops in for the full 60 min boil.

-----

After hitting up the LHBS, twice, for everything I needed, I realized that (1) I've never done an AG before, (2) I've never done a stout before, and (3) the ingredients list left off a recipe, so I appropriated an Irish Dry Stout recipe from here:

Dry Irish Stout

(5 gallons/19 L, all-grain)

OG = 1.040 FG = 1.008

IBU = 35 SRM = ~38 ABV = 4.1%

Ingredients

7.5 lbs. (3.4 kg) 2-row pale malt (preferably Maris Otter)

12 oz. (0.34 kg) roasted barley (400500 °L)

2.0 oz. (57 kg) chocolate malt (300400 °L)

1/2 tsp. baking soda (added to mash)

1 tsp. Irish moss

9.25 AAU Perle hops (bittering) (1.2 oz./33 g of 8% alpha acid)

Wyeast 1084 or White Labs WLP004

3/4 cup corn sugar (for bottling)

Step by Step

Bring 9 quarts (9 L) of water to 166 °F (74 °C) and mix in the malts and baking soda. The temperature should fall between 154156 °F (6869 °C). Hold mash for 60 minutes before sparging. Recirculate the wort until clear and then run off wort to the kettle. Once the top of the grain bed is covered by an inch of wort, begin sparging with 176 °F (80 °C) water. Collect 6 gallons (23 L) of wort. Bring wort to a boil, add hops and boil for 60 minutes. Add Irish moss 5 minutes before the end of boil. Cool wort to 70 °F (21 °C), aerate, pitch yeast and ferment at 70 °F (21 °C). Rack after 10 days and a second time in another 14 days. Then prime, bottle and hold 7 days before drinking.

This is the classic stout to serve on mixed gas using a stout faucet. If this method is desired, skip the priming and bottling step and use the technique detailed on page 33.

Extract with grains option: An extract version of this beer can be made by substituting the pale malt for 6.0 lbs. (2.7 kg) of light liquid malt extract or 4.25 lbs. (1.9 kg) of light dry malt extract.

Minus the Irish Moss, it gave me the right series of steps to flounder my way through whole mess.

-----

First issue: Sparging was WAY harder than I expected and resulted in a lot of stickiness and some lost mash.

Second issue: A lot more fat stayed in the cake slurry than I'd have hoped.

Third issue: I'm not sure if it's the properties of the mash or the fat, but that wort would NOT cool down. I was up late.

Fourth issue: I picked the wrong container to cool to measure gravity, and by that time of night I was done trying, so this is yet another beer for which I will have no ABV.

----

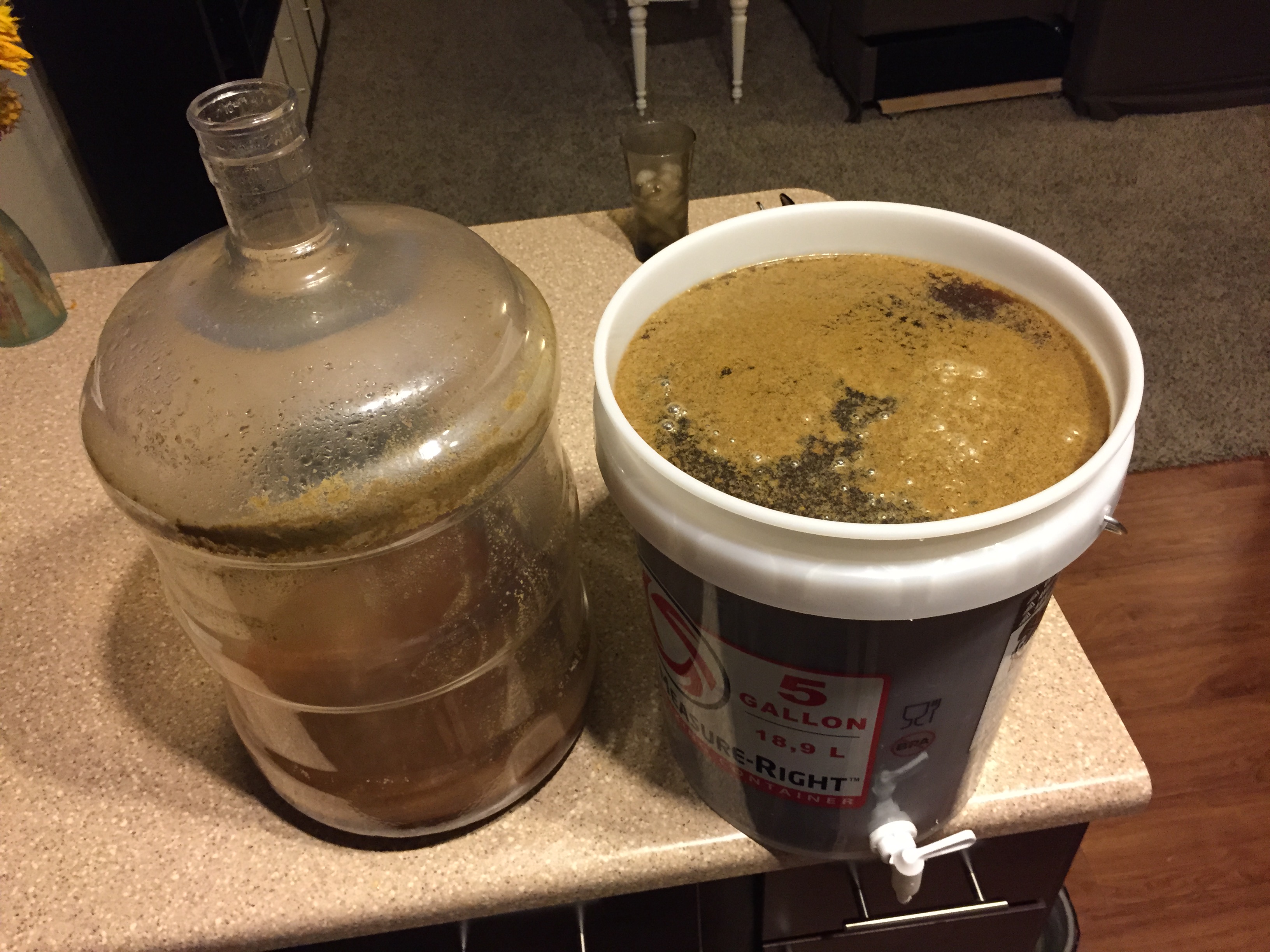

Somehow, despite the fat that settled on top of the carboy, it started fermenting like a champ somewhere between 7 and 15 hours in. I'm tentatively excited that my Let Them Eat Cake Stout, which I made specifically for my girlfriend who rather enjoys big, heavy beers during the Texas summer, might actually make it.

Updates to come.

For now, the ingredients as I remember them were:

10 lbs Domestic 2 Row

1 lb flaked barley

.75 lb roasted barley

.25 lb chocolate row

.5 oz Target (?) hops, for which I substituted the Fuggle my LHBS had for the similar profile.

English Pale Ale Yeast (not sure of any more specifics)

1 sheet cake, baked, crumbled, boiled, simmered as slurry for 15 minutes, chilled and scrapped for fat.

Grain gets mashed for 60 at 154F and cake slurry goes into the mash before boil. Hops in for the full 60 min boil.

-----

After hitting up the LHBS, twice, for everything I needed, I realized that (1) I've never done an AG before, (2) I've never done a stout before, and (3) the ingredients list left off a recipe, so I appropriated an Irish Dry Stout recipe from here:

Dry Irish Stout

(5 gallons/19 L, all-grain)

OG = 1.040 FG = 1.008

IBU = 35 SRM = ~38 ABV = 4.1%

Ingredients

7.5 lbs. (3.4 kg) 2-row pale malt (preferably Maris Otter)

12 oz. (0.34 kg) roasted barley (400500 °L)

2.0 oz. (57 kg) chocolate malt (300400 °L)

1/2 tsp. baking soda (added to mash)

1 tsp. Irish moss

9.25 AAU Perle hops (bittering) (1.2 oz./33 g of 8% alpha acid)

Wyeast 1084 or White Labs WLP004

3/4 cup corn sugar (for bottling)

Step by Step

Bring 9 quarts (9 L) of water to 166 °F (74 °C) and mix in the malts and baking soda. The temperature should fall between 154156 °F (6869 °C). Hold mash for 60 minutes before sparging. Recirculate the wort until clear and then run off wort to the kettle. Once the top of the grain bed is covered by an inch of wort, begin sparging with 176 °F (80 °C) water. Collect 6 gallons (23 L) of wort. Bring wort to a boil, add hops and boil for 60 minutes. Add Irish moss 5 minutes before the end of boil. Cool wort to 70 °F (21 °C), aerate, pitch yeast and ferment at 70 °F (21 °C). Rack after 10 days and a second time in another 14 days. Then prime, bottle and hold 7 days before drinking.

This is the classic stout to serve on mixed gas using a stout faucet. If this method is desired, skip the priming and bottling step and use the technique detailed on page 33.

Extract with grains option: An extract version of this beer can be made by substituting the pale malt for 6.0 lbs. (2.7 kg) of light liquid malt extract or 4.25 lbs. (1.9 kg) of light dry malt extract.

Minus the Irish Moss, it gave me the right series of steps to flounder my way through whole mess.

-----

First issue: Sparging was WAY harder than I expected and resulted in a lot of stickiness and some lost mash.

Second issue: A lot more fat stayed in the cake slurry than I'd have hoped.

Third issue: I'm not sure if it's the properties of the mash or the fat, but that wort would NOT cool down. I was up late.

Fourth issue: I picked the wrong container to cool to measure gravity, and by that time of night I was done trying, so this is yet another beer for which I will have no ABV.

----

Somehow, despite the fat that settled on top of the carboy, it started fermenting like a champ somewhere between 7 and 15 hours in. I'm tentatively excited that my Let Them Eat Cake Stout, which I made specifically for my girlfriend who rather enjoys big, heavy beers during the Texas summer, might actually make it.

Updates to come.