Did some more work on the brewery this weekend:

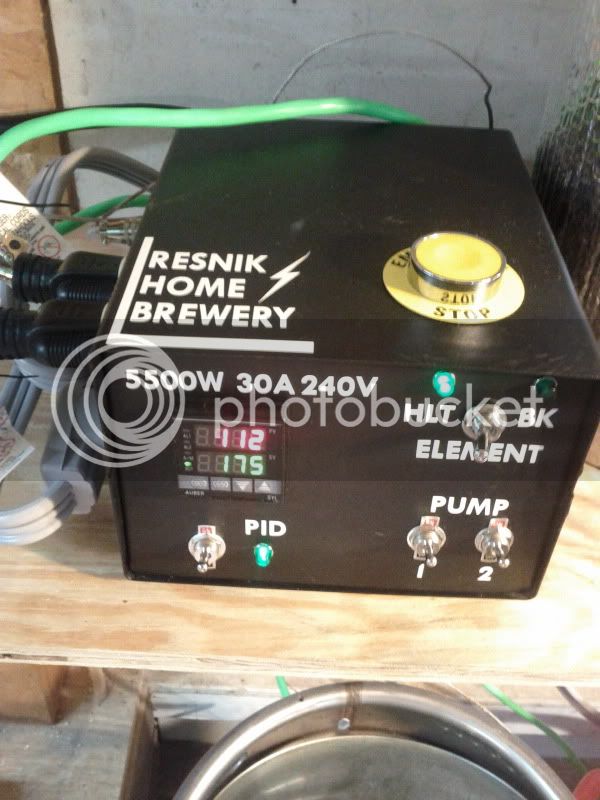

Got most of the decals on the control panel, thanks to Bobby_M at Brewhardware for the sweet custom labels!

Got the RTD installed on the output of the heat exchanger, and ran an autotune session with about 10 gallons of water in the HLT and ~4 gallons in the MLT. (I’ll do another autotune on the next brew session I think).

Temperatures in the MLT had about a 3 to 4 degrees lag behind the water in the HLT during the initial heating, but they evened out pretty quickly once the set temp of 175 was hit. I recirculated in the HLT to keep constant agitation, while also recirculating the ‘mash’ with the output valve half open.

Also did some work on my logo, I’d appreciate some feedback on this if anyone has any suggestions. I’m relearning GIMP since its been awhile since I used any graphics program other than Picasa and Paint.

Other updates to the brewery:

- Installed stainless ½” NPT to ½” OD compression elbows in the BK and HLT in-port to use as a whirlpool/recirc agitators (thanks to my dad for bringing these fittings home from work, saved me about $50 bucks!)

- Took the pump out of the toolbox. I think I like having them mounted permanently under the brewstand better.

- Adjusted the BK’s diptube to pull more from the side of the kettle since I will now be whirlpooling. I just bent the copper tubing out towards the vessel wall with my hands/vise grips.