jnlipas

Member

Hello,

Yesterday I kegged my first batch of beer (I know, I got ambitious and went straight to kegging instead of bottling) and I did not pull on the relief valve after I filled the keg with beer. Once I started filling the keg with co2 I did pull on the relief valve some and I didn't have any beer shoot up but I could hear the keg filling with co2. I am worried that there is still O2 in the keg and that I've ruined my beer .

.

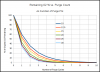

My other question is that I am confused as to what PSI I should be carbonating my beer at. I don't have a kegerator or other means of keeping the keg cool, so my plan was to just let it carbonated for a week or so before filling a growler and chilling it. A coworker of mine said to leave the regulator at 12 PSI and the tank turned on with the shutoff valve open so there is co2 constantly flowing in to it. I've also read other forums/watched videos where people are carbonating it and then disconnecting it. Currently I have the regulator set to 20 PSI and and have the tank open/shutoff valve open. Is there a surefire way to carbonate the way I am trying to (outside of a kegerator in about a 65 - 70 degree basement)? I'm just really nervous about screwing up my first batch.

Thanks for your time.

Yesterday I kegged my first batch of beer (I know, I got ambitious and went straight to kegging instead of bottling) and I did not pull on the relief valve after I filled the keg with beer. Once I started filling the keg with co2 I did pull on the relief valve some and I didn't have any beer shoot up but I could hear the keg filling with co2. I am worried that there is still O2 in the keg and that I've ruined my beer

My other question is that I am confused as to what PSI I should be carbonating my beer at. I don't have a kegerator or other means of keeping the keg cool, so my plan was to just let it carbonated for a week or so before filling a growler and chilling it. A coworker of mine said to leave the regulator at 12 PSI and the tank turned on with the shutoff valve open so there is co2 constantly flowing in to it. I've also read other forums/watched videos where people are carbonating it and then disconnecting it. Currently I have the regulator set to 20 PSI and and have the tank open/shutoff valve open. Is there a surefire way to carbonate the way I am trying to (outside of a kegerator in about a 65 - 70 degree basement)? I'm just really nervous about screwing up my first batch.

Thanks for your time.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)