str1p3s

Well-Known Member

- Joined

- Jan 5, 2016

- Messages

- 221

- Reaction score

- 148

I've been kicking around the idea of trying to purge the keg with CO2 and do a closed transfer to try to improve my process but never landed on a good way to do it. Filling it with starsan and pushing it out with CO2 has never sounded appealing to me. I don't usually have 5+ gallons of starsan on hand and the thought of either leaving a small amount at the bottom or doing some acrobatics to get every bit out didn't sound like something I wanted to get into.

I came across this thread:

https://www.homebrewtalk.com/forum/threads/keg-purging-with-active-fermentation.628658/

where doug293cz did the math (very impressive) and showed that if you connect the CO2 blowoff from an active fermentation into your serving keg, it will effectively purge the keg.

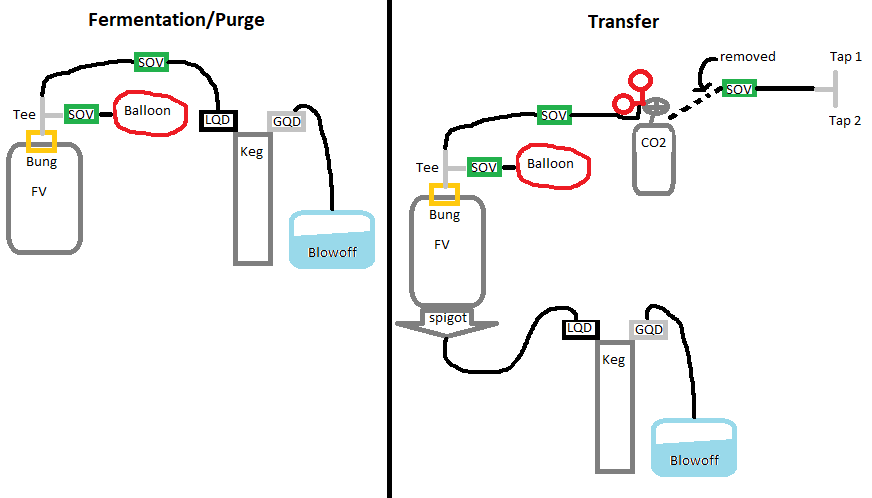

So I thought up a process and drew some diagrams (attached) to map out what I want to try. I decided to post it here for anyone interested and/or anyone who sees any problems or improvements to it.

Even if it's not perfect, it's better than what I do now (nothing!).

A few notes:

- I made something I'm calling the "CO2 capture apparatus" that prevents oxygen/starsan suck back when cold crashing. It is a hose barb tee that splits the blowoff tube. One end goes to a mylar balloon to capture CO2 and the other vents off remaining CO2 after the balloon fills.

- I'm using these ball valves on all the hoses. They are polypropylene. I don't think vinyl would work with these, so I didn't try it. I pressure and leaked tested them at 40psi:

https://www.amazon.com/gp/product/B01N1UZFML/?tag=skimlinks_replacement-20

I have one going from

- FV to balloon

- FV to purge line

- CO2 regulator to taps in kegerator

I use them because they easily detach (so used like QDs) and so that I can minimize having to pull the gas QD off of kegs because that is a PITA sometimes.

Here we go:

Purge:

1) Start of fermentation, place CO2 capture apparatus on FV with balloon valve closed to keep initial head space oxygen and any blow off out of the balloon

2) Connect vent tube of CO2 capture apparatus to liquid post of sanitized keg

3) Connect gas post to a jar of starsan to vent purged air

4) After a day or so, open balloon valve to capture CO2

5) Balloon fills, CO2 redirected to keg to purge. Optionally, close balloon valve

6) When ready to cold crash, disconnect keg QDs and open balloon valve. CO2 in balloon will account for suck back

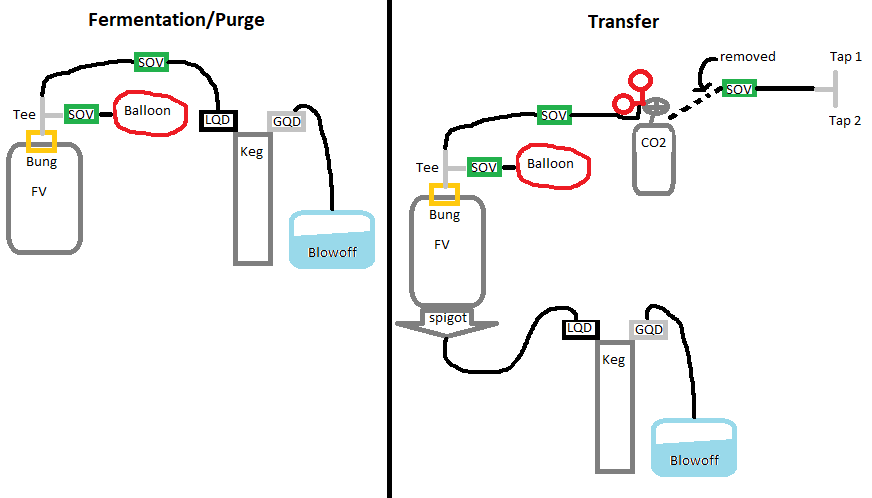

Transfer:

1) Close shut off valve of purging tube to liquid QD

2) Disconnect purge tube from liquid QD at (now closed) purge valve

3) Move FV from chamber onto high surface

4) Move keg to position under FV to gravity feed (if doing gravity feed only in step 8) and connect liquid QD to spigot and gas QD to blow off

5) Close shut off valves on CO2 regulator and on tube leading to taps (so I don't lose pressure in my kegs that are currently on tap)

6) Disconnect CO2 at (now closed) tap valve, leaving valve with taps to keep it closed, and reconnect to the purge valve from the fermenter

7) Open spigot and begin transfer. Balloon will finish deflating whatever is left from cold crash as the beer drains and displaces CO2 in keg which will vent into blow off

8) As the balloon deflates, slowly open the CO2 regulator until balloon is full again to keep flow going (not sure yet what the regulator should be set to)

OR

8) Close balloon valve, set the regulator to 1-2 psi (or more. again, not sure yet. need to test) and pressure transfer the rest of the way

9) When FV is empty or beer is flowing into the blow off, stop the transfer

10) If needed, tip the keg towards the gas post to dump a small amount of beer out to get the level below the dip tube

11) disconnect liquid and gas QDs

Any thoughts, suggestions and/or criticisms are welcome!

I came across this thread:

https://www.homebrewtalk.com/forum/threads/keg-purging-with-active-fermentation.628658/

where doug293cz did the math (very impressive) and showed that if you connect the CO2 blowoff from an active fermentation into your serving keg, it will effectively purge the keg.

So I thought up a process and drew some diagrams (attached) to map out what I want to try. I decided to post it here for anyone interested and/or anyone who sees any problems or improvements to it.

Even if it's not perfect, it's better than what I do now (nothing!).

A few notes:

- I made something I'm calling the "CO2 capture apparatus" that prevents oxygen/starsan suck back when cold crashing. It is a hose barb tee that splits the blowoff tube. One end goes to a mylar balloon to capture CO2 and the other vents off remaining CO2 after the balloon fills.

- I'm using these ball valves on all the hoses. They are polypropylene. I don't think vinyl would work with these, so I didn't try it. I pressure and leaked tested them at 40psi:

https://www.amazon.com/gp/product/B01N1UZFML/?tag=skimlinks_replacement-20

I have one going from

- FV to balloon

- FV to purge line

- CO2 regulator to taps in kegerator

I use them because they easily detach (so used like QDs) and so that I can minimize having to pull the gas QD off of kegs because that is a PITA sometimes.

Here we go:

Purge:

1) Start of fermentation, place CO2 capture apparatus on FV with balloon valve closed to keep initial head space oxygen and any blow off out of the balloon

2) Connect vent tube of CO2 capture apparatus to liquid post of sanitized keg

3) Connect gas post to a jar of starsan to vent purged air

4) After a day or so, open balloon valve to capture CO2

5) Balloon fills, CO2 redirected to keg to purge. Optionally, close balloon valve

6) When ready to cold crash, disconnect keg QDs and open balloon valve. CO2 in balloon will account for suck back

Transfer:

1) Close shut off valve of purging tube to liquid QD

2) Disconnect purge tube from liquid QD at (now closed) purge valve

3) Move FV from chamber onto high surface

4) Move keg to position under FV to gravity feed (if doing gravity feed only in step 8) and connect liquid QD to spigot and gas QD to blow off

5) Close shut off valves on CO2 regulator and on tube leading to taps (so I don't lose pressure in my kegs that are currently on tap)

6) Disconnect CO2 at (now closed) tap valve, leaving valve with taps to keep it closed, and reconnect to the purge valve from the fermenter

7) Open spigot and begin transfer. Balloon will finish deflating whatever is left from cold crash as the beer drains and displaces CO2 in keg which will vent into blow off

8) As the balloon deflates, slowly open the CO2 regulator until balloon is full again to keep flow going (not sure yet what the regulator should be set to)

OR

8) Close balloon valve, set the regulator to 1-2 psi (or more. again, not sure yet. need to test) and pressure transfer the rest of the way

9) When FV is empty or beer is flowing into the blow off, stop the transfer

10) If needed, tip the keg towards the gas post to dump a small amount of beer out to get the level below the dip tube

11) disconnect liquid and gas QDs

Any thoughts, suggestions and/or criticisms are welcome!

Last edited: