beerme70

Well-Known Member

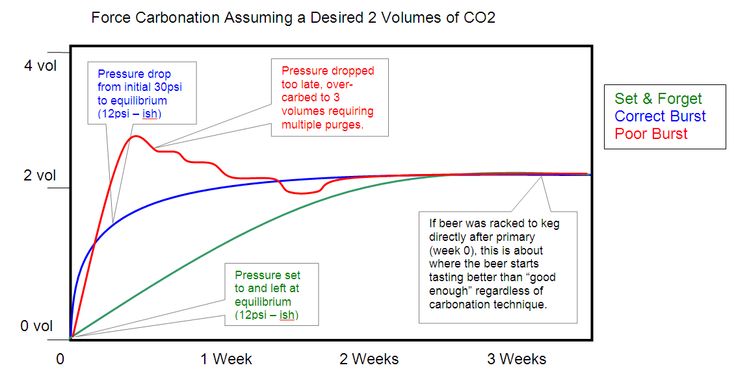

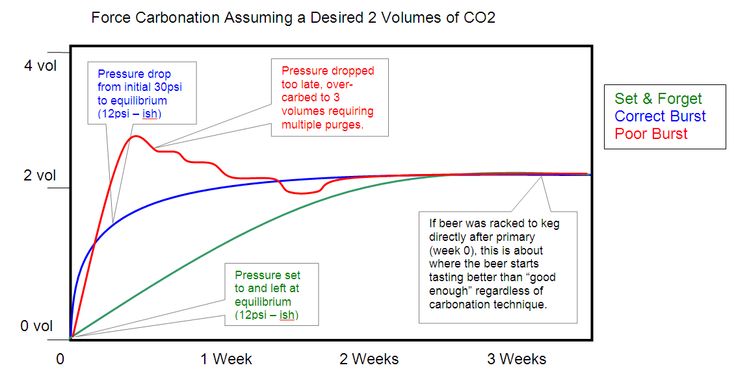

I've always been in the "patience is a virtue" crowd, and just set the gauge to the serving pressure and wait a little longer. It'll get there.

36 - 48 hrs at 30 psi is too long for 2.5 gal of beer. 36 hrs works pretty well for me with 5 gal. Because the lower volume of beer only needs to absorb half the total amount of CO2, you should only hold at 30 psi for 18 hrs. Waiting a day or two after dropping the pressure will improve the beer taste and perception of carbonation.

Overcarbed beer foams excessively, and then seems undercarbed or flat. Sounds like what you are observing.

Brew on

That makes sense! I got the 36-48 hours advice from someone at my LHBS but don't think I mentioned that I do small batches.

I did the instant solution for overcarbed keg thing on this forum and it worked, tastes better and I'm getting great pours. Thanks for the info!

"Force" Carbing is not a misomer. The "force" of the air pressure is mucher higher with the 2 different methods.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

How long does the set it and forget it method take to carbonate a smaller batch (2.5 gallons)? I know the burst carb method takes less time with a smaller batch size, is the same true for set it and forget it?

I'll admit I didn't read the whole thread, but tried a search and came up short. How does temperature effect the co2 burst? For example, if my beer goes into my kegs from the carboy in the basement at a temperature of low 60's, how will that effect the burst? I believe lower temps are more effective for carbonating. The beer in the keezer is cooler than 60, but not when the keg first goes into the keezer and gets the co2 hooked up to it.

After 24 hours at 36 PSI, I poured myself some beer. I didn't get a crazy amount of head out of the first pint like I do with a fully carb'd keg, but it also seems less than the graph implies.

The beer will carb slower at higher temperatures at a constant pressure.

The CO2 absorption rate is proportional to the difference between headspace pressure and the equilibrium pressure at the beer temperature for the current level of carbonation in the beer. Beer in the fermenter at 65˚F has an equilibrium CO2 pressure of 0 psi and contains 0.8 volumes of CO2. If you pressurize to 36 psi, the pressure difference is 36 psi. If the same beer were cooled to 38˚F, it would still have 0.8 volumes of CO2, but the equilibrium pressure would be -6.73 psi (don't worry about it being negative, as it is gauge pressure, the absolute pressure is 7.96 psi.) So, for the cold beer the pressure difference would be 36 psi + 6.73 psi = 42.73 psi. Thus the cold beer will absorb CO2 about 42.73 / 36 = 1.19 time faster. There's probably another temperature term that also affects rate of absorption, but I don't know what it is off hand.

Brew on

ACtually, after reading this again and some other posts I think I get it now. 30 PSI for about 24 hours, then bring it down to 12 or so PSI and then let it sit for another 7-9 days at that to let it equalize, then serve.

For the boost carb method is it assuming beer is at fermentation temps or chilled serving temp for the first 24

Hours at 30psi? I'm kegging later and I have a beer chilled at serving temp (38f).

If I set to 30 psi for 24 hours at serving temp, drop the psi to serving chart pressure and purge (when I purge should I relieve all headspace pressure?), should I be set?

Arrgh! The plot from the original post has gone missing! Bad juju!

Google still has a copy

Where is the line for: set it, shake the heck out of it, then forget it?

^^or you could turn up the psi to 30 and put the keg on its side and agitate it, carbing it up real quick and drink it an hour later. Thats what I did on Saturday. Different strokes different folks!

How long do you agitate it for? I tried this once and way over carbed it so I've been scared to try it again.

That's the risk with over pressure plus agitation for burst carbing. A safer way of burst carbing is to put 30 psi on a cold keg for 36 hrs (no more), and no agitation. Then vent the headspace, and set to serving pressure.

Brew on