[...]day_trippr: How are you running the probe in for the controller? Just resting the lid on the probe cord or?

The gasket

is compliant enough to let you get away with just draping it over the edge of the chassis, though you might have to add some length to the probe wire. Alternative, my old keezer (rest in peace) used an external controller and I ran the probe wire through a connector mounted at the back edge of the lid, in parallel with the gas lines.

The

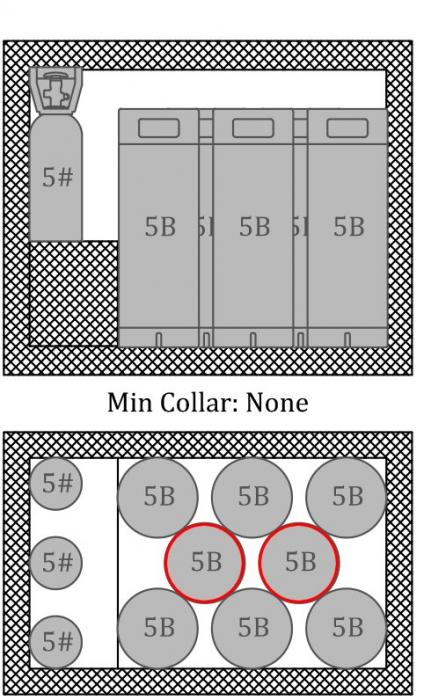

new keezer (long may it live!) - being a dispensing appliance - has a lot more going on than just keeping beer cold, so as I had to tear it down to implement a lot of stuff anyway I allowed my inner engineer to go a bit nutty

I mounted an MH1210 controller in the front edge of the lid, then brought the temperature sensor connection through the liner with a dangling 2.1mm socket (on the right end of the lid - I'll replace that with the fixed 2.1mm/5.5mm receptacle I didn't have on hand at the time when I get a chance). The probe wire was way too short to make the trip from controller to kegs anyway, hence the socket - but that'll also allow easy replacement of the probe should it ever fail (I have two spares on hand).

I ran two CO2 feeds through MFL bulkheads and a four wire control/DC power cable through a DIN socket, all located on the back edge of the lid, in parallel with the original AC feed to the lid lamp (I use that to power the MH1210 guts as well). The control lines run through the MH1210 relay and the 12V/GND lines go to a liner-mounted 2.5mm/5.5mm socket (on the left side of the lid) for the tower cooler, stirring fan and a fan that drives air into my little Eva-Dry 500 drier on the keezer floor (which I found a year ago doesn't do crap unless air is pushed into it).

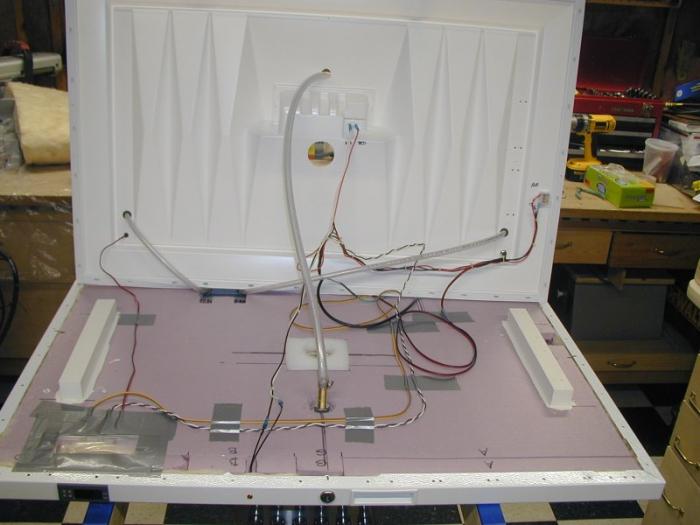

Finally, I fabricated a system power controller and mounted it in the back of the dolly (recessed to allow near-flush positioning against the wall). It has a

regulated 12V/2A power supply (not the unregulated POS wall wart shown in the bench testing pic) with a control switch and status indicator, a 30A relay controlled by the MH1210 to switch the compressor, and a Leviton duplex outlet split for the switched compressor side and the always-on AC feed for the lid lamp/MH1210. The relay circuit preempted the need to run a pair of big fat 14 gauge cables in and out of the keezer to the MH1210 - which now only has to switch a low current 12V circuit to the 30A relay coil. I'm hoping that will add to the longevity of the MH1210. We'll see.

The last pic shows the works inside the lid. The two sleepers are hard points for the primary gas distributor at one end and for (future) secondary regs at the other end. There's also an inch thick 12"x28" piece of wood under the foam that the tower and drip tray bolt into. The wood bits and rigid foam are all epoxied to the lid and stiffened it up like you wouldn't believe, as the stock lid just has a batt of fiberglass tossed in and was so flimsy with the liner removed I could lift a corner up three inches without the other three corners moving at all.

It all ended up working perfectly, with awesome pours (there's 72 feet of Bevlex-200 in there) Couldn't be more pleased with the result.

Hope this might provide some ideas

Cheers!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)