dnelson1025

Well-Known Member

Hey all,

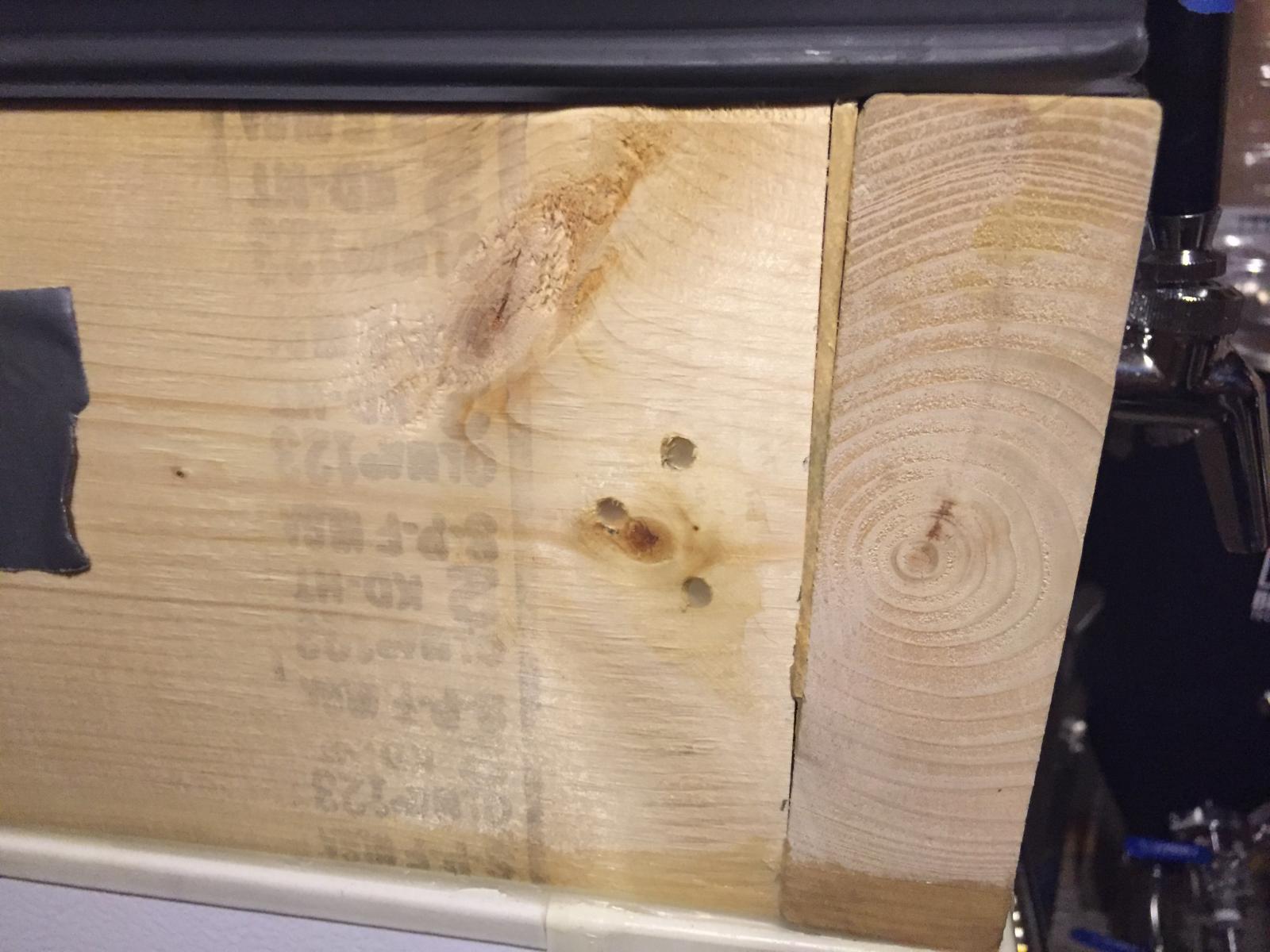

I've finally gotten around to building a collar for my new freezer - problem is it's a little crooked (see picture). It's about 3/4" away from the top of the freezer on the front left side.

Does anyone have any ideas on how to fix this? Should I just scrap it and start over? I'm pretty sure it just happened to be the way the wood is shaped, but feel free to correct me and tell me I'm a terrible carpenter. Thanks!

I've finally gotten around to building a collar for my new freezer - problem is it's a little crooked (see picture). It's about 3/4" away from the top of the freezer on the front left side.

Does anyone have any ideas on how to fix this? Should I just scrap it and start over? I'm pretty sure it just happened to be the way the wood is shaped, but feel free to correct me and tell me I'm a terrible carpenter. Thanks!

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)