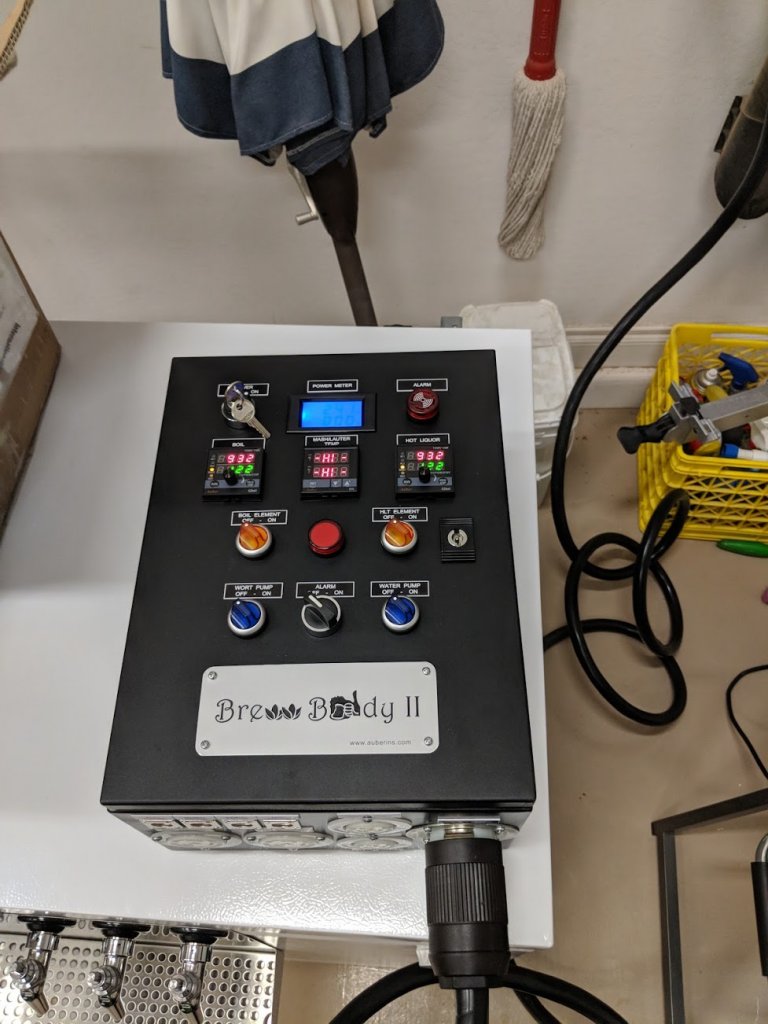

So I sent an email to Auber earlier this week about building a 50a version of the Brew Buddy so I could do back to back batches utilizing 2x ezboil controllers at the same time. They were really responsive and let me know they had one coming real soon. Sure enough, I was able to place the order for it just an hour ago on the newly listed item!

https://www.auberins.com/index.php?main_page=product_info&cPath=64_65&products_id=731

I have 50a service going into my RV garage for this today, super stoked to move to electric. I'm only 6 batches in but I got the brew bug pretty bad. I'll throw up some pics when it arrives!

https://www.auberins.com/index.php?main_page=product_info&cPath=64_65&products_id=731

I have 50a service going into my RV garage for this today, super stoked to move to electric. I'm only 6 batches in but I got the brew bug pretty bad. I'll throw up some pics when it arrives!

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)