For my fermenters, I used 3 SS Brewtech conicals. Using these conicals was one of things I was looking forward to the most in my new brewery. I have to say combining these with a floor drain and moving beer under CO2 pressure has been a brewing life changer for me. No more difficult to clean and move glass carboys. The thing I love the most about the conicals is I can dump the yeast from the bottom in a couple minutes and harvest it, and BANG I am in Secondary! I find that I do not need to wash my yeast after harvesting because I get so little trub coming from the Electric Brewery design. I just harvest the yeast into a sanitized bowl with a pouring lip and then split it between two sanitized glass jars (mason jars will do) and store them in my conditioning cooler.

When I got the conicals, I also bought their FTSS system that contained a pump, tubing, lid with cooling coil and thermowell, neoprene jacket for the conicals and a controller. I broke into the metal case that SS Brewtech used to house the controller, pulled it out and mounted it into my own controller box. I put all three pumps in the same keg inside my keezer and ran the cooling and return lines through the front of the collar. I ran the 3 wires for the three pumps plus my keezer temperature sensor through the same hole through the side of keezer collar. Future upgrades will include quick disconnects for the posts coming out of the top of the fermenter lid, insulating the vinyl lines, and creating an insulated disk to sit on top of the fermenter for getting to lagering temps more easily.

Parts Needed:

- SS Brewtech Conicals (or some other brand/type)

- SS Brewtech FTSS system (or some other controller, chilling coil or other some such system)

- Aquarium pump

- 3/8" vinyl tubing

- Sharkbite connectors

- hard sharkbite tubing for going through collar

- keg or some other reservoir

- water/a bit of glycol and a cap full of star san as the cooling fluid (so far in 4 months, I have had no crud growing in my lines)

- keezer or some other way of chilling cooling fluid mix to 39º

Now for some pics:

SS Brewtech conical with stock FTSS system installed.

Pic of the chilling coil that sits in the beer.

pump by jonymac, on Flickr

pump by jonymac, on Flickr

This is the pump that comes with the FTSS system.

IMG_8860 by jonymac, on Flickr

IMG_8860 by jonymac, on Flickr

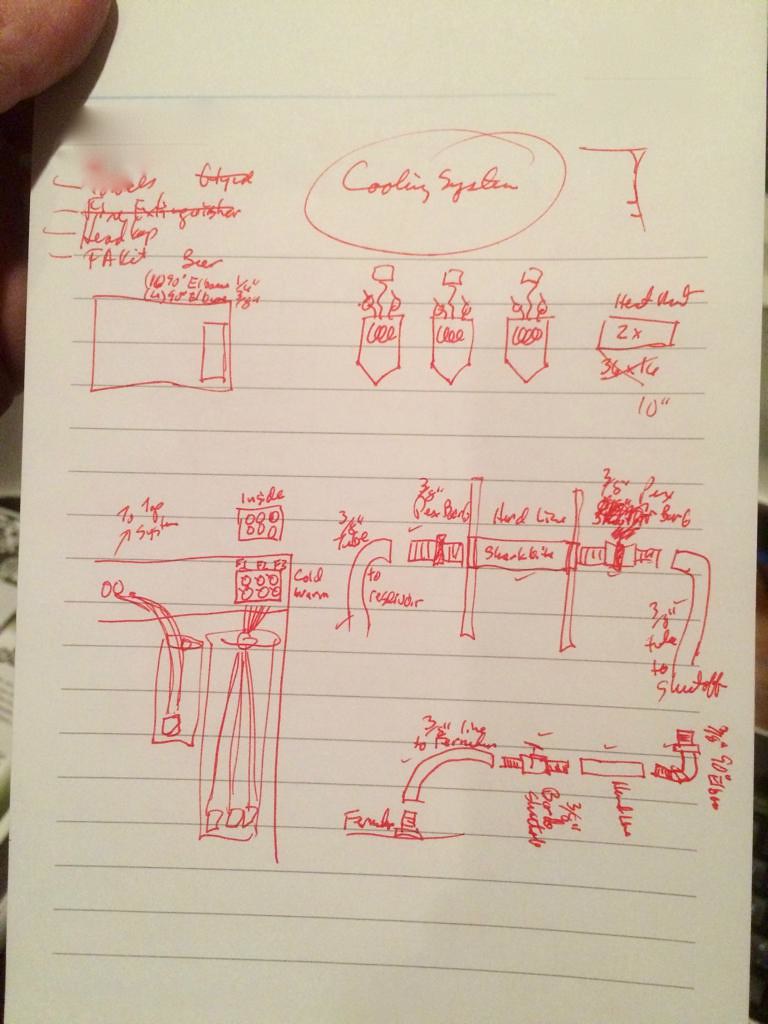

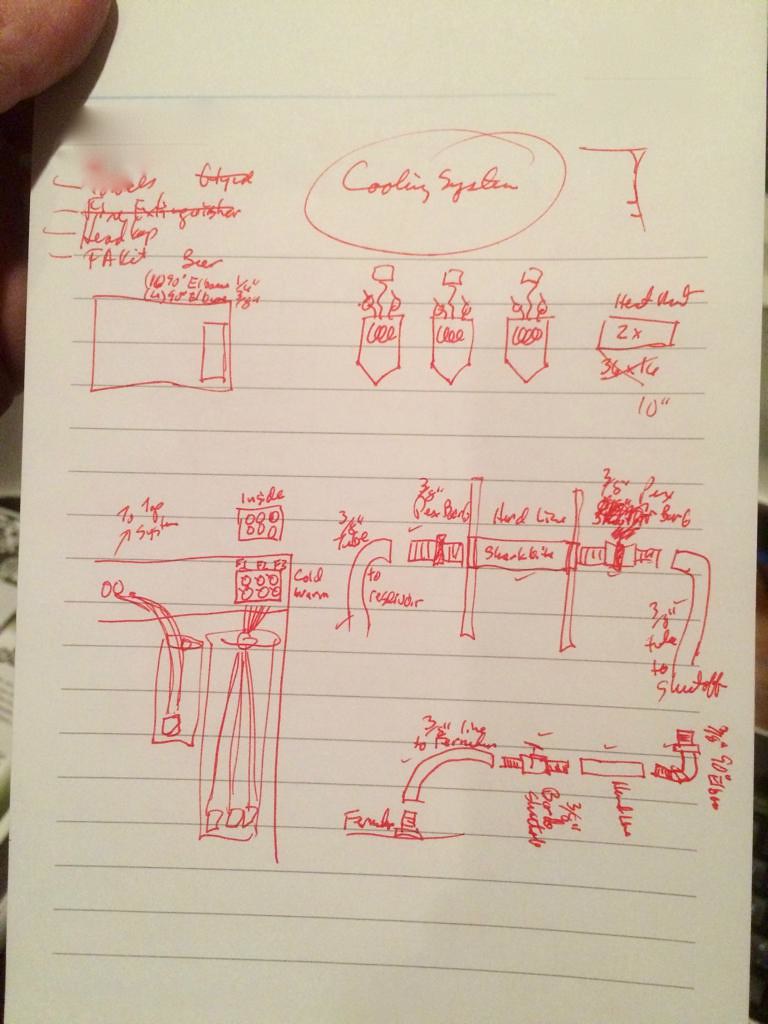

My sketch showing how the bits and pieces fit together.

IMG_8888 by jonymac, on Flickr

IMG_8888 by jonymac, on Flickr

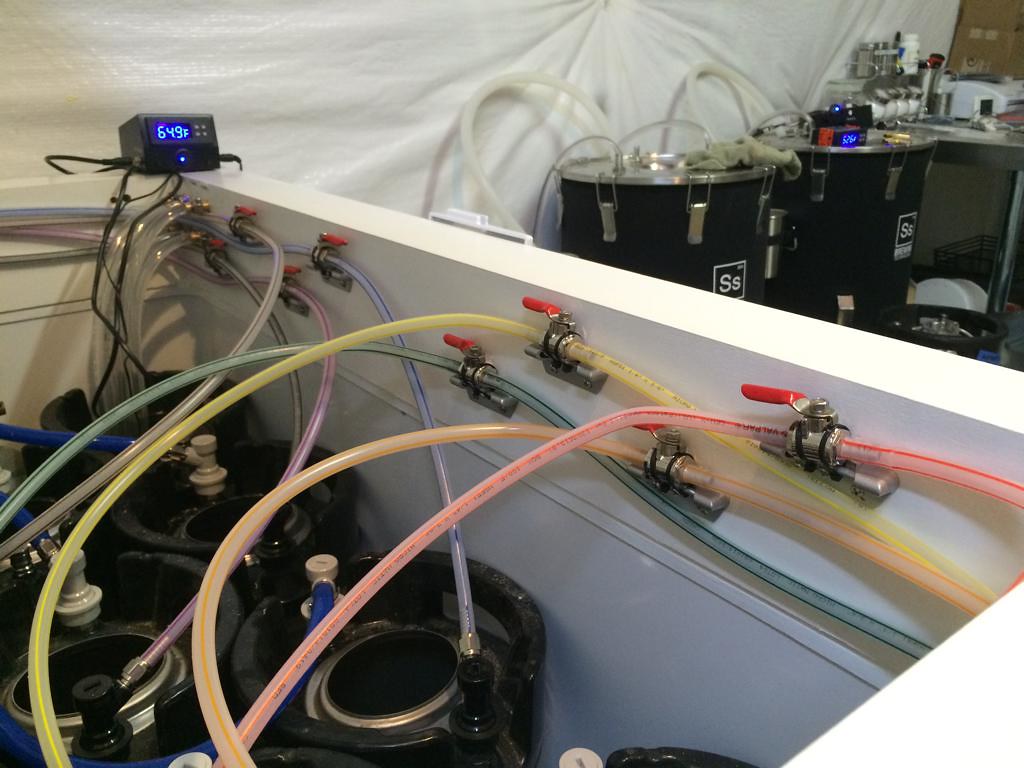

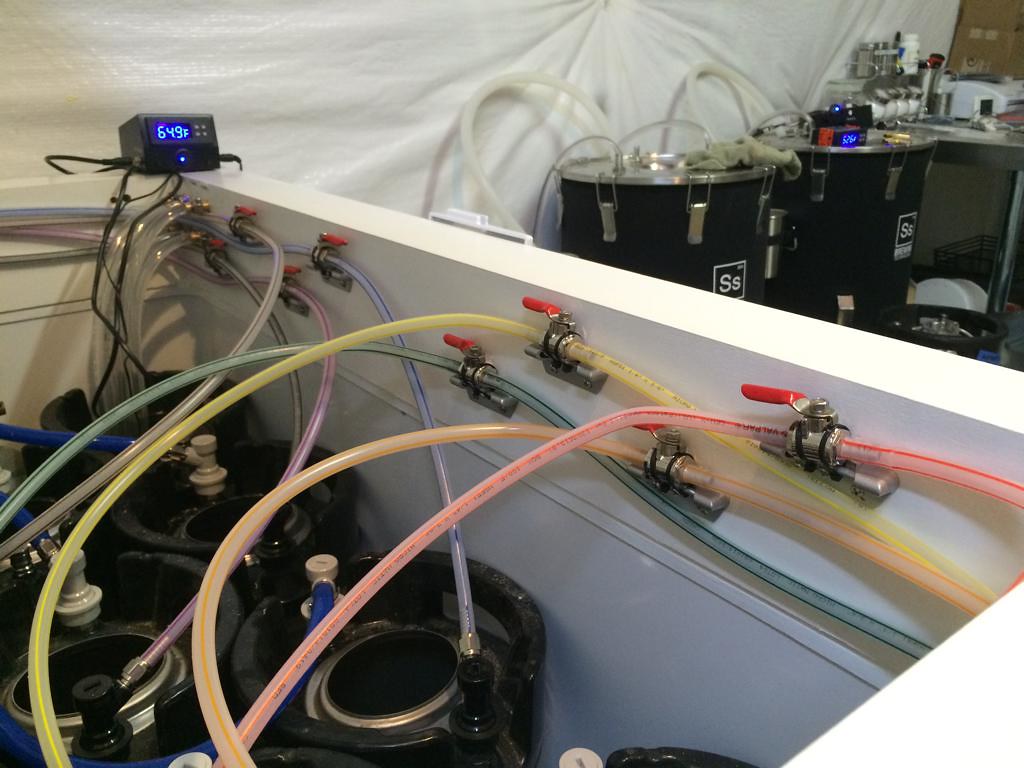

This shows the vinyl tubing coming out of the keg in the corner through the collar and out to the fermenters.

IMG_8885 by jonymac, on Flickr

IMG_8885 by jonymac, on Flickr

You can see the keg with the tubing and pumps in the right front corner. In the right back corner is the half keg sitting on the compressor bump used for the tap cooling reservoir with its hot and cold tubing.

IMG_9857 by jonymac, on Flickr

IMG_9857 by jonymac, on Flickr

Here you can see the tubing going into the top of the fermenters. I put shutoff valves at the end of the tubes so I don't spill cooling fluid all over when connecting and disconnecting the cooling system from the lids.

Fermenter 1 on the left has Ballast Point's Sculpin Ale fermenting set at 65º. Fermenter 2 in the middle has Kal's Electric IPA finishing up its fermentation at 68º. The third fermenter to the right has a hard cider holding until it's ready to be kegged. You can also see the room temperature is at 79º that day as we were hooking up a vent in the room to the HVAC system and had just turned the heat on - I had forgotten to close the vent after it was installed and hadn't regulated how much air was going to the brewery with the HVAC damper.

When I got the conicals, I also bought their FTSS system that contained a pump, tubing, lid with cooling coil and thermowell, neoprene jacket for the conicals and a controller. I broke into the metal case that SS Brewtech used to house the controller, pulled it out and mounted it into my own controller box. I put all three pumps in the same keg inside my keezer and ran the cooling and return lines through the front of the collar. I ran the 3 wires for the three pumps plus my keezer temperature sensor through the same hole through the side of keezer collar. Future upgrades will include quick disconnects for the posts coming out of the top of the fermenter lid, insulating the vinyl lines, and creating an insulated disk to sit on top of the fermenter for getting to lagering temps more easily.

Parts Needed:

- SS Brewtech Conicals (or some other brand/type)

- SS Brewtech FTSS system (or some other controller, chilling coil or other some such system)

- Aquarium pump

- 3/8" vinyl tubing

- Sharkbite connectors

- hard sharkbite tubing for going through collar

- keg or some other reservoir

- water/a bit of glycol and a cap full of star san as the cooling fluid (so far in 4 months, I have had no crud growing in my lines)

- keezer or some other way of chilling cooling fluid mix to 39º

Now for some pics:

SS Brewtech conical with stock FTSS system installed.

Pic of the chilling coil that sits in the beer.

pump by jonymac, on Flickr

pump by jonymac, on FlickrThis is the pump that comes with the FTSS system.

IMG_8860 by jonymac, on Flickr

IMG_8860 by jonymac, on FlickrMy sketch showing how the bits and pieces fit together.

IMG_8888 by jonymac, on Flickr

IMG_8888 by jonymac, on FlickrThis shows the vinyl tubing coming out of the keg in the corner through the collar and out to the fermenters.

IMG_8885 by jonymac, on Flickr

IMG_8885 by jonymac, on FlickrYou can see the keg with the tubing and pumps in the right front corner. In the right back corner is the half keg sitting on the compressor bump used for the tap cooling reservoir with its hot and cold tubing.

IMG_9857 by jonymac, on Flickr

IMG_9857 by jonymac, on FlickrHere you can see the tubing going into the top of the fermenters. I put shutoff valves at the end of the tubes so I don't spill cooling fluid all over when connecting and disconnecting the cooling system from the lids.

Fermenter 1 on the left has Ballast Point's Sculpin Ale fermenting set at 65º. Fermenter 2 in the middle has Kal's Electric IPA finishing up its fermentation at 68º. The third fermenter to the right has a hard cider holding until it's ready to be kegged. You can also see the room temperature is at 79º that day as we were hooking up a vent in the room to the HVAC system and had just turned the heat on - I had forgotten to close the vent after it was installed and hadn't regulated how much air was going to the brewery with the HVAC damper.