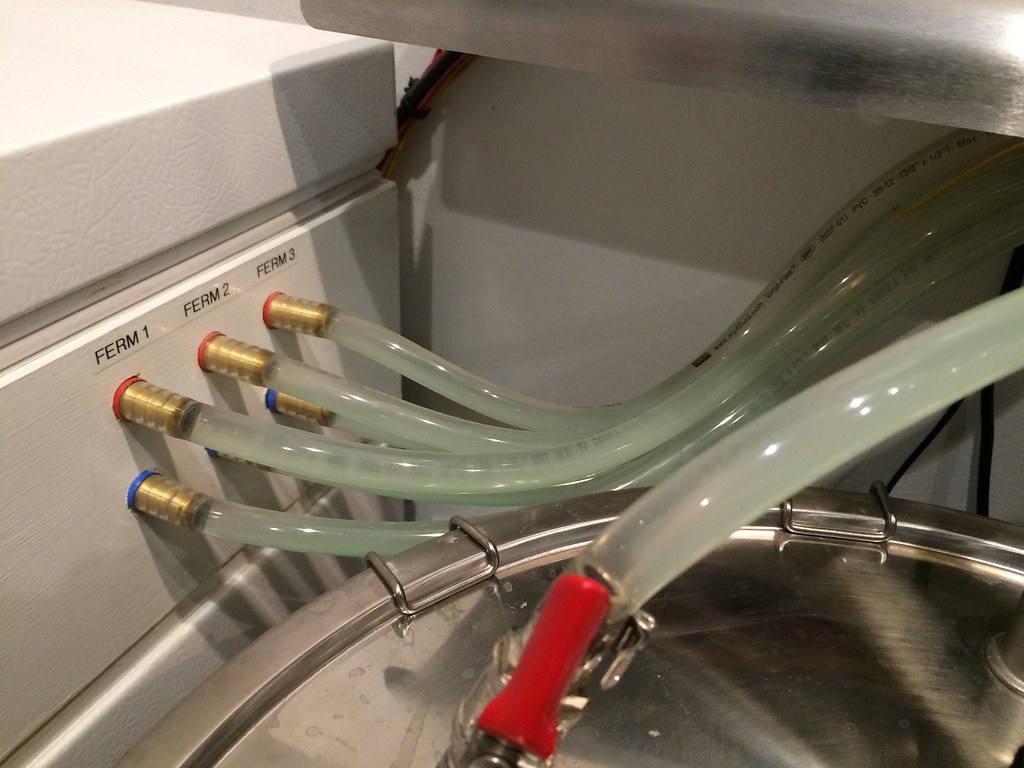

My brewery has a keezer (Whirlpool 14.8 Cu Ft http://www.whirlpool.com/-[EH155FXBQ]-1021418/EH155FXBQ/) that holds 8 kegs to serve my 8 taps, 1 keg that holds cleaner/sanitizer used to clean out the lines and taps, 1 keg that holds 3 aquarium pumps to cool my three conical fermenters, 1 reservoir that contains a glycol mix that runs out of the keezer into the freezer (GE 7 Cu Ft http://products.geappliances.com/appliance/gea-specs/FCM7SHWW) through the tap and back to the reservoir, and 1 10lb nitrogen tank to feed my stout tap. I keep a scuba sized CO2 tank under my bar and the high pressure feed runs through the wall into the brewery. I used Micromatic's 8 line trunk line to run from the keezer to the taps, stripped off the insulation and ran them inside the keezer. They are all color coded. I placed beer shutoff valves inside the keezer to make it easier to change kegs without spilling beer in the keezer, to have a place to add flow meters for my RaspberryPints app, and to be able to shutoff beer to the taps and then lock the keezer cuz I have a 15 year old...

I built collars for both the keezer and the freezer out of 1x stock - 1x6 for the keezer and 1x4 for the freezer to run my tubing through. I filled the gap between the 1x with expanding foam and capped it with a thin strip of 1x and then primed and painted it white to match the keezer and freezer. I secured the collars to the keezer and freezer using silicone adhesive caulk. For the Keezer, I used Micromatic quad CO2 distribution panels and built a CO2 distribution board external to the keezer to be able to easily view, shutoff and distribute CO2 to clear kegs and to push beer from the conicals to kegs. I have enough room in the keezer for a pail of DampRid, and a layer of growlers on top of the kegs. My fermentation refrigeration controller controls the temp of the keezer and keeps it between 33º and 34º. I added a plug in moisture absorber that I pull out of the keezer and plug in to dry out every month or so - this results in very little condensation in the keezer.

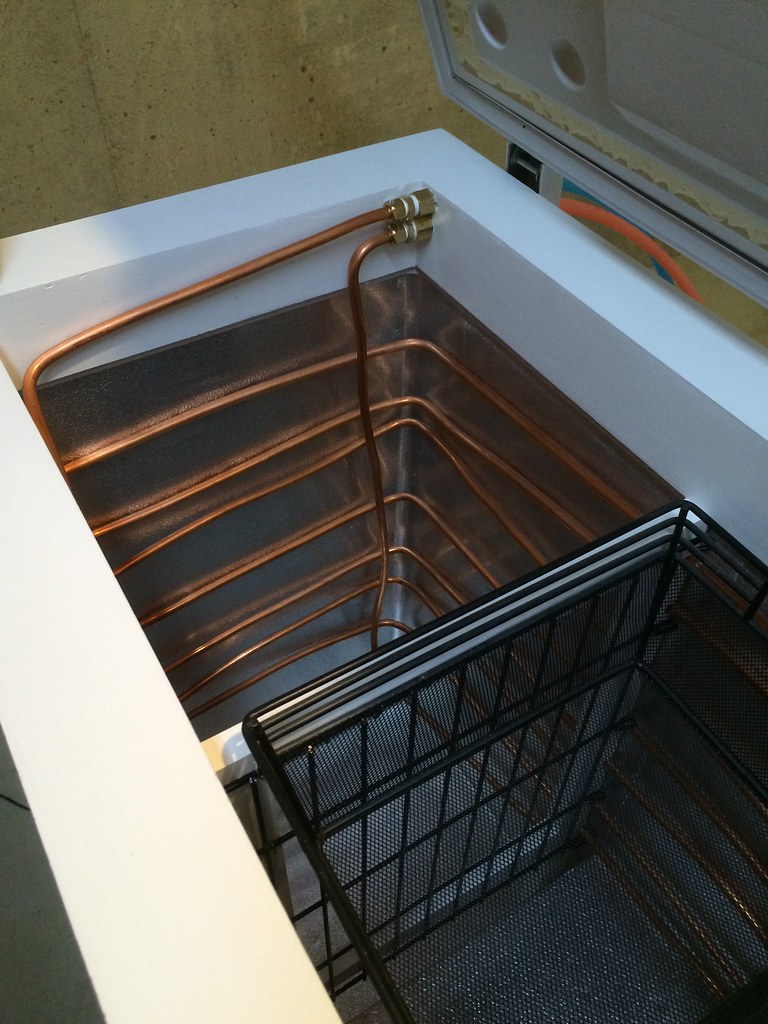

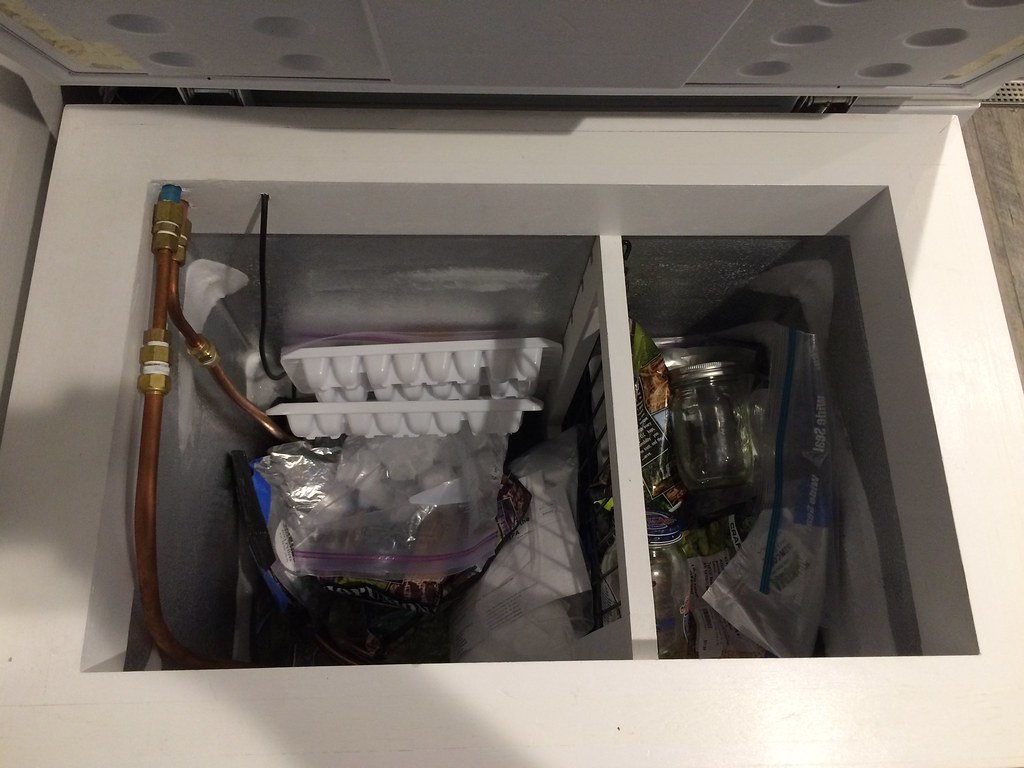

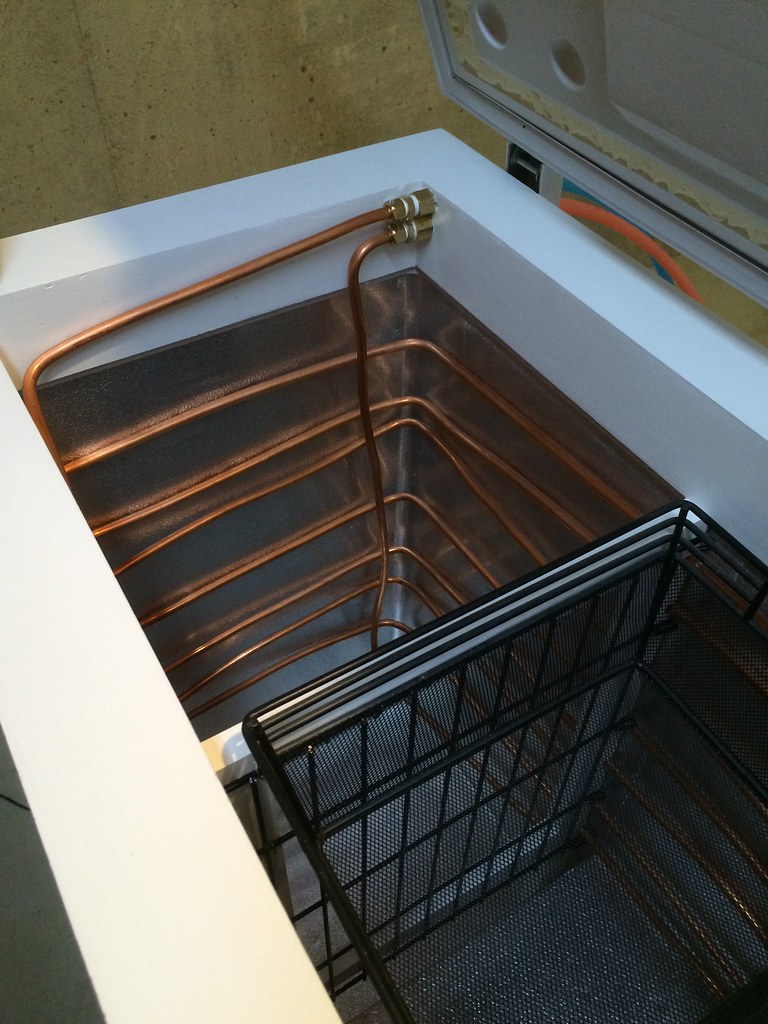

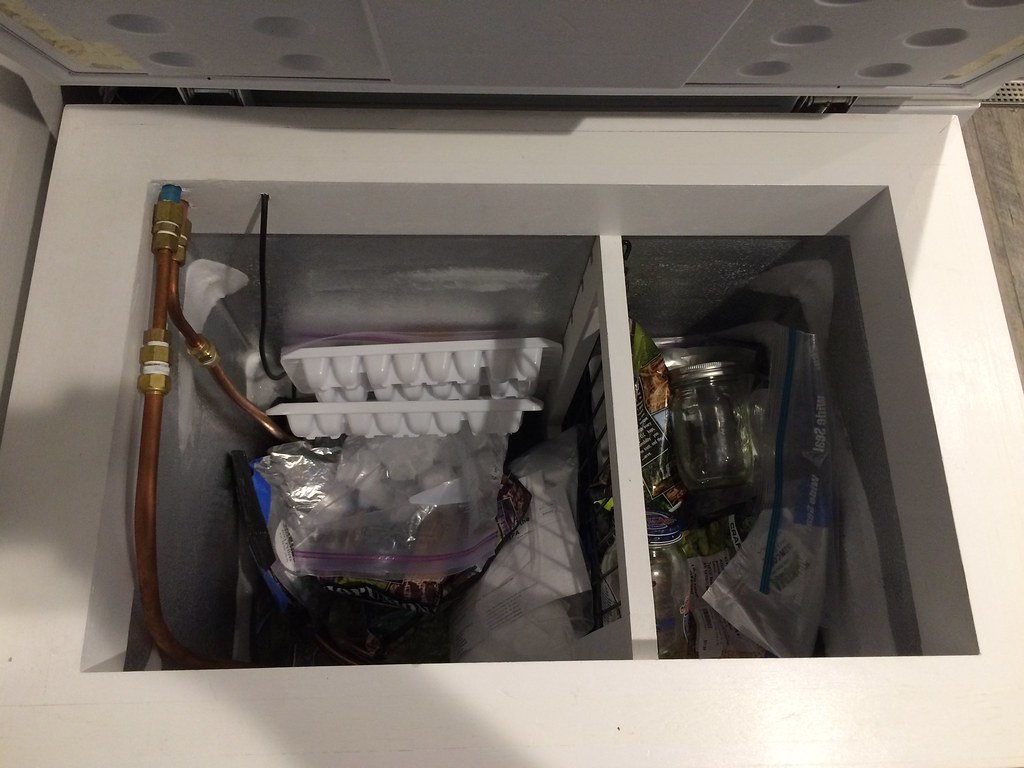

In the freezer I have 50' of 3/8" copper coil that sits on the bottom of the freezer kept at 10º. I use the freezer for hops, ice, moonshine and a cold coil for the tap pump that keeps the taps at 39º. If I am lagering a beer in the fermentation tank, I put the aquarium pump in the tap reservoir and can get the fermenter below 53º. Below are pics of the setups:

FREEZER:

IMG_8896 by jonymac, on Flickr

IMG_8896 by jonymac, on Flickr

Freezer collar being clamped.

IMG_8897 by jonymac, on Flickr

IMG_8897 by jonymac, on Flickr

Version 1 of the copper coil in the freezer - I had to upgrade from 1/4" tubing to 3/8" tubing to get the glycol to flow better, instead of bending it all around the interior (pain in the ass) I left it coiled in the bottom.

IMG_8905 by jonymac, on Flickr

IMG_8905 by jonymac, on Flickr

I built a separator out of 1x2 and cut up a bit of an old dog kennel to use as the screen to hold all the hops on 1 side of the freezer.

IMG_8906 by jonymac, on Flickr

IMG_8906 by jonymac, on Flickr

Freezer collar installed, primed and painted.

IMG_8907 by jonymac, on Flickr

IMG_8907 by jonymac, on Flickr

Detail of copper tubing going through freezer collar.

IMG_0161 by jonymac, on Flickr

IMG_0161 by jonymac, on Flickr

Freezer with 3/8" tubing, full of hops, moonshine and showing temperature sensor coming through collar.

KEEZER:

keezercollar by jonymac, on Flickr

keezercollar by jonymac, on Flickr

Keezer collar partially filled with expanding foam.

IMG_8855 by jonymac, on Flickr

IMG_8855 by jonymac, on Flickr

Clamping collar to keezer using silicone adhesive.

IMG_8856 by jonymac, on Flickr

IMG_8856 by jonymac, on Flickr

Micromatic quad distribution panels for controlling CO2 individually for each keg.

IMG_0164 by jonymac, on Flickr

IMG_0164 by jonymac, on Flickr

Keezer view of CO2 valves and beer distribution lines.

IMG_8887 by jonymac, on Flickr

IMG_8887 by jonymac, on Flickr

CO2 valves left side.

IMG_8886 by jonymac, on Flickr

IMG_8886 by jonymac, on Flickr

CO2 valves right side.

IMG_8888 by jonymac, on Flickr

IMG_8888 by jonymac, on Flickr

Beer shutoff valves for each keg.

IMG_8891 by jonymac, on Flickr

IMG_8891 by jonymac, on Flickr

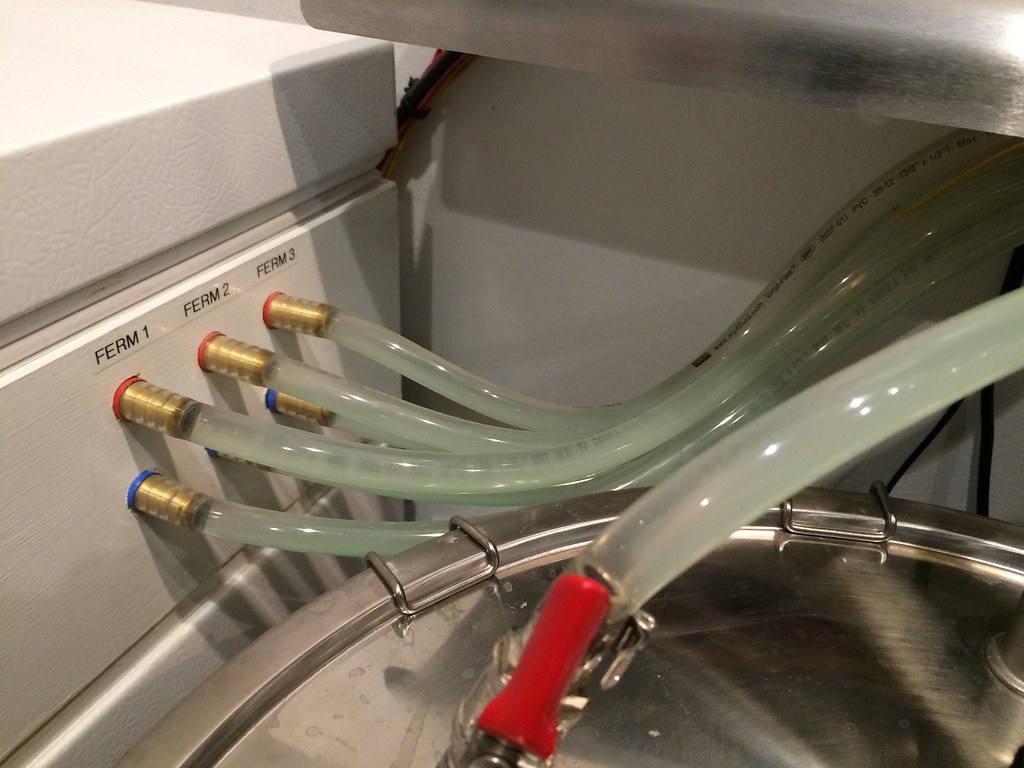

Mating beer lines with trunk line and cooling lines with freezer coil.

IMG_0162 by jonymac, on Flickr

IMG_0162 by jonymac, on Flickr

Vinyl lines coming from cooling keg aquarium pumps to three fermenters.

IMG_8869 by jonymac, on Flickr

IMG_8869 by jonymac, on Flickr

CO2 distribution board prior to being painted.

IMG_0159 by jonymac, on Flickr

IMG_0159 by jonymac, on Flickr

Freezer, keezer, distribution panel and fermenters in place being controlled by my fermentation refrigeration controller.

JonyMac

I built collars for both the keezer and the freezer out of 1x stock - 1x6 for the keezer and 1x4 for the freezer to run my tubing through. I filled the gap between the 1x with expanding foam and capped it with a thin strip of 1x and then primed and painted it white to match the keezer and freezer. I secured the collars to the keezer and freezer using silicone adhesive caulk. For the Keezer, I used Micromatic quad CO2 distribution panels and built a CO2 distribution board external to the keezer to be able to easily view, shutoff and distribute CO2 to clear kegs and to push beer from the conicals to kegs. I have enough room in the keezer for a pail of DampRid, and a layer of growlers on top of the kegs. My fermentation refrigeration controller controls the temp of the keezer and keeps it between 33º and 34º. I added a plug in moisture absorber that I pull out of the keezer and plug in to dry out every month or so - this results in very little condensation in the keezer.

In the freezer I have 50' of 3/8" copper coil that sits on the bottom of the freezer kept at 10º. I use the freezer for hops, ice, moonshine and a cold coil for the tap pump that keeps the taps at 39º. If I am lagering a beer in the fermentation tank, I put the aquarium pump in the tap reservoir and can get the fermenter below 53º. Below are pics of the setups:

FREEZER:

IMG_8896 by jonymac, on Flickr

IMG_8896 by jonymac, on FlickrFreezer collar being clamped.

IMG_8897 by jonymac, on Flickr

IMG_8897 by jonymac, on FlickrVersion 1 of the copper coil in the freezer - I had to upgrade from 1/4" tubing to 3/8" tubing to get the glycol to flow better, instead of bending it all around the interior (pain in the ass) I left it coiled in the bottom.

IMG_8905 by jonymac, on Flickr

IMG_8905 by jonymac, on FlickrI built a separator out of 1x2 and cut up a bit of an old dog kennel to use as the screen to hold all the hops on 1 side of the freezer.

IMG_8906 by jonymac, on Flickr

IMG_8906 by jonymac, on FlickrFreezer collar installed, primed and painted.

IMG_8907 by jonymac, on Flickr

IMG_8907 by jonymac, on FlickrDetail of copper tubing going through freezer collar.

IMG_0161 by jonymac, on Flickr

IMG_0161 by jonymac, on FlickrFreezer with 3/8" tubing, full of hops, moonshine and showing temperature sensor coming through collar.

KEEZER:

keezercollar by jonymac, on Flickr

keezercollar by jonymac, on FlickrKeezer collar partially filled with expanding foam.

IMG_8855 by jonymac, on Flickr

IMG_8855 by jonymac, on FlickrClamping collar to keezer using silicone adhesive.

IMG_8856 by jonymac, on Flickr

IMG_8856 by jonymac, on FlickrMicromatic quad distribution panels for controlling CO2 individually for each keg.

IMG_0164 by jonymac, on Flickr

IMG_0164 by jonymac, on FlickrKeezer view of CO2 valves and beer distribution lines.

IMG_8887 by jonymac, on Flickr

IMG_8887 by jonymac, on FlickrCO2 valves left side.

IMG_8886 by jonymac, on Flickr

IMG_8886 by jonymac, on FlickrCO2 valves right side.

IMG_8888 by jonymac, on Flickr

IMG_8888 by jonymac, on FlickrBeer shutoff valves for each keg.

IMG_8891 by jonymac, on Flickr

IMG_8891 by jonymac, on FlickrMating beer lines with trunk line and cooling lines with freezer coil.

IMG_0162 by jonymac, on Flickr

IMG_0162 by jonymac, on FlickrVinyl lines coming from cooling keg aquarium pumps to three fermenters.

IMG_8869 by jonymac, on Flickr

IMG_8869 by jonymac, on FlickrCO2 distribution board prior to being painted.

IMG_0159 by jonymac, on Flickr

IMG_0159 by jonymac, on FlickrFreezer, keezer, distribution panel and fermenters in place being controlled by my fermentation refrigeration controller.

JonyMac