You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

It's Time for my bar build!

- Thread starter EZCyclone

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

kenmyfam

Well-Known Member

- Joined

- Feb 10, 2013

- Messages

- 126

- Reaction score

- 47

It's funny how that purple wall is coming through as blue now that I have cleaned my phone camera.

It sure changed the shade a peg or 2

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

Back from China. Were you saving the update photo's till I got home ???

Ha ha, sure have! No, I've just been crazy busy. I got little things done here and there. Took a week and went to Kansas to help dad with mothers new kitchen. I pulled out all theold floor, floor joists and shattered beam. Replaced with three LVL beams, new joists, new subfloor. The walls had already been stripped back to the studs. So ran all new plumbing, gas line, electrical, low voltage for cab lights, insulation and got the drywall up and one wall ready for paint.

It was a busy week, took moms plaster 1940's 192'^2 kitchen to a drywalled 580'^2 room.

On top of that, the ad I used to sell my old bar generated requests from other buyers to build a new bar for sale. So I've been working on a bar, but one that's already sold. Oh yeah, add midterms and the wedding in 71 days, that's kept me busy. Lol. Ill see what I can get together for update pics soon.

In the mean time here's a few pics of the bar frame I'm building for a customer.

Well, I got all the bar tops and the counter tops cut from the particle board that came in Wednesday. This is for my bar, not the second one. Lol.

Fiance came home sick, so that's the end of my work day. Tomorrow we have a hockey game to go to, and Monday I've got a damn exam, so Sunday will be most likely be study day. There's always something in the way, lol.

Fiance came home sick, so that's the end of my work day. Tomorrow we have a hockey game to go to, and Monday I've got a damn exam, so Sunday will be most likely be study day. There's always something in the way, lol.

Looking great my friend. How did the exam go ????

I am heading to our Alabama plant next week.

Thanks Paul, I need to get my butt back to it. Which exam? lol. I've had so damn many this sem. Had a Latin exam today, not my best work. Have a Chem exam on Monday.

Birthday was the 2nd and I got a nice new pickup truck for it. So that made for a good week. lol. I got the customers bar done and it was picked up Saturday. So now I have to get a gazebo built by this weekend as it's the "Bridesmaids brunch" at our house out on our patio. Then, maybe, I hope, I can get back to work on my bar room.

Bar is tile top, skinned in a special textile I use for lighting them up with LED's and what not. Hardwood maple trim conditioned with my special blend, stained with royal walnut, finished with a semi gloss poly. The back is left open for adding in the lighting and to save this customer money.

Bar is designed and built to break and fold up on one side so that it will pack into a standard pickup for delivery. The tile is removed and packed for shipping and a 2x4 strap bolted directly into the bar top. This makes it a free standing unit that only needs strapped in to keep it from sliding.

kenmyfam

Well-Known Member

- Joined

- Feb 10, 2013

- Messages

- 126

- Reaction score

- 47

Just looked back and saw the exam I was talking about was a geology exam. It went well. Lol

Glad to hear it. Looks like you never have time to stop for a breather right now. All looking great though. New pick up, very nice and hope you had a Happy Birthday"

NickTheGreat

Well-Known Member

- Joined

- Apr 17, 2012

- Messages

- 1,291

- Reaction score

- 531

Nice truck! And bar. But the truck!!!

Nice truck! And bar. But the truck!!!

Lol no kidding right Nick! It was one Hell of a birthday present. The Fiance did well! Lol. I did have a good birthday, but it was crazy busy. Never time to rest anymore. It feels like it will be that way till after the wedding in June.

I got the weight boxes finished yesterday, and three of the legs chiseled out. One more to go, the. I really hope I can get the concrete poured in the boxes tomorrow and maybe even still get it together for Sunday. I guess we will see. My list of other things I need done by Sunday is to long to fit on one full sheet of paper. So maybe not.

Nearly 7 months since my last post, kinda sad isn't it...

So where do I begin? Well when I last saw you all I had just delivered that frats bar. They loved it and life went on. That was back in the second week of April. With the wedding approaching like a freight train and spring bearing down on me like a mother in law I had to switch my focus to the patio. Got the gazebo built and ready for all the visiting guests soon to come. Then my brother got married, and then school finals, and well, since I panned the gold for my wife's ring a year earlier, and designed and intended to make it myself I needed to get to the making part! So I did and got my wife's beautiful ring made in time for the wedding! Next thing I knew It was June 6th and we were getting married. June 6th D-Day! Which is great because I will never forget it! It was great and I got to marry an amazing woman! We spent 2 weeks in Mexico where our honeymoon was interrupted by tropical storm Bill Tropical_Storm_Bill_(2015). Funny part of the story is it went on over the Yucatán Peninsula and then we flew back into the storm when it was in Dallas. So we got stranded in Dallas for the night and flew out the next morning landing in the middle of the storm as it tore up Des Moines! Bastard got us three times!!!

Anyway...

Upon returning I found a spring had formed under my wood shop and all my tools were rusty from the water in the building. Most of the wood stored there was molding!! SO, I gutted the garage, and built an "As-fast-as-possible" impromptu shop at my home. Oddly enough it is twice the size as my "pro" shop, but has not produced near the same amount of pieces! lol. So I spent a few months trying to get going there, and of course had to work this summer building custom pieces.

Now the bar has to get done so I can start building baby furniture.... My assistant Brewer will be here the end of March!!

I'm sure I'm forgetting about 90 things, but the important part is I'm back on the bar project!!!

So where do I begin? Well when I last saw you all I had just delivered that frats bar. They loved it and life went on. That was back in the second week of April. With the wedding approaching like a freight train and spring bearing down on me like a mother in law I had to switch my focus to the patio. Got the gazebo built and ready for all the visiting guests soon to come. Then my brother got married, and then school finals, and well, since I panned the gold for my wife's ring a year earlier, and designed and intended to make it myself I needed to get to the making part! So I did and got my wife's beautiful ring made in time for the wedding! Next thing I knew It was June 6th and we were getting married. June 6th D-Day! Which is great because I will never forget it! It was great and I got to marry an amazing woman! We spent 2 weeks in Mexico where our honeymoon was interrupted by tropical storm Bill Tropical_Storm_Bill_(2015). Funny part of the story is it went on over the Yucatán Peninsula and then we flew back into the storm when it was in Dallas. So we got stranded in Dallas for the night and flew out the next morning landing in the middle of the storm as it tore up Des Moines! Bastard got us three times!!!

Anyway...

Upon returning I found a spring had formed under my wood shop and all my tools were rusty from the water in the building. Most of the wood stored there was molding!! SO, I gutted the garage, and built an "As-fast-as-possible" impromptu shop at my home. Oddly enough it is twice the size as my "pro" shop, but has not produced near the same amount of pieces! lol. So I spent a few months trying to get going there, and of course had to work this summer building custom pieces.

Now the bar has to get done so I can start building baby furniture.... My assistant Brewer will be here the end of March!!

I'm sure I'm forgetting about 90 things, but the important part is I'm back on the bar project!!!

First shot is my faithful shop helper! He's great help!

So I made a trip to my suppliers and got a load of hard rock maple(150bf) and a pallet of 3/4 maple cabinet ply. Made up some face frames and then testing those frames in the bar on the cabs. Got the wine cab together too. Damn thing is a BEAST weighs 103# without face frame or finish! it's pretty dang big, it will hold 106 bottles.

I have three face frames yet to make and should be ready for a day of sanding and the spray staining and finish.

So I made a trip to my suppliers and got a load of hard rock maple(150bf) and a pallet of 3/4 maple cabinet ply. Made up some face frames and then testing those frames in the bar on the cabs. Got the wine cab together too. Damn thing is a BEAST weighs 103# without face frame or finish! it's pretty dang big, it will hold 106 bottles.

I have three face frames yet to make and should be ready for a day of sanding and the spray staining and finish.

Calfj60

Well-Known Member

Looks really nice

Looks really nice

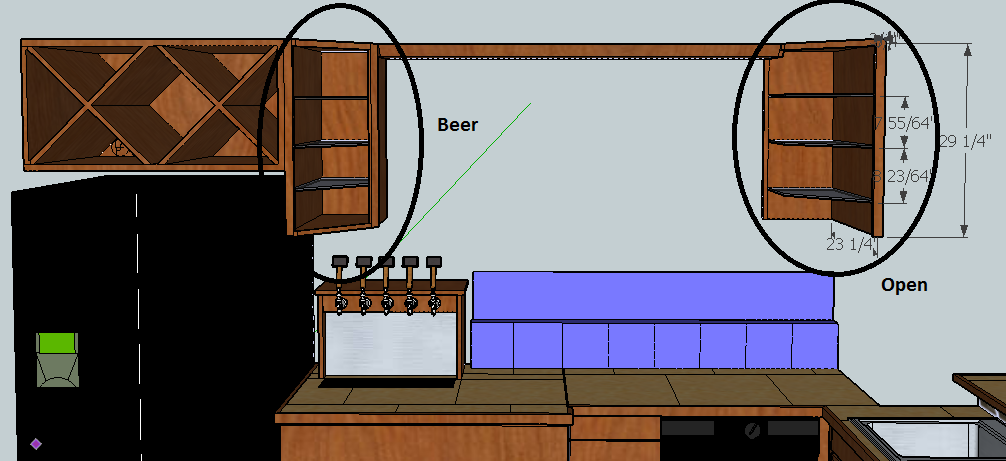

Thank ya sir! Lot left to do. I didn't get as much done today as I would have liked, but so is life. It's all slow going right now. Lots of odd pieces to fit. I got all the dados cut for the polycarb shelves in both the "beer" and "open" cabs. Faceframe is cut for the "beer" cab. I need to cut the face frame for the "open" cab and then the skin for the bar and the piece between the upper cabinets, then I can sand for days!

Singletrack

Because it's judgement that defeats us.

Will there be a ring build thread? Were you able to sneak a tiny Cy on it somewhere?

Will there be a ring build thread? Were you able to sneak a tiny Cy on it somewhere?

Ha ha, not exactly home brew is it? There is a video on YouTube.

[ame]https://www.youtube.com/watch?v=dfITKYyGZ2Q[/ame]

Not exactly a step by step. This is the video we played at the reception to surprise her. She had no idea I had done any of this, lol.

Not a ton of update pics but got every piece sanded and wetted to preraise the grain. tomorrow I will hit it all with 400g and get to staining. Pics tomorrow night should be far more brown! This pic is the "beer" cabinet. Got the faceframe all finished.

Well I spent the whole day knocking down raised grain with 400g and then staining. Ran out of stain with about 4 sq feet left to go so have to run to Des Moines to pic up some more stain after class in the morning. I'll be finishing them tomorrow with General EnduroVar satin. Took up a hell of a lot of space, and used 3 pints of General Medium brown dye stain.

![20151110_180222[1].jpg 20151110_180222[1].jpg](https://cdn.homebrewtalk.com/data/attach/268/268158-20151110-180222-1-.jpg)

![20151110_180324[1].jpg 20151110_180324[1].jpg](https://cdn.homebrewtalk.com/data/attach/268/268159-20151110-180324-1-.jpg)

![20151110_184109[1].jpg 20151110_184109[1].jpg](https://cdn.homebrewtalk.com/data/attach/268/268160-20151110-184109-1-.jpg)

![20151110_184126[1].jpg 20151110_184126[1].jpg](https://cdn.homebrewtalk.com/data/attach/268/268161-20151110-184126-1-.jpg)

![20151110_202718[1].jpg 20151110_202718[1].jpg](https://cdn.homebrewtalk.com/data/attach/268/268162-20151110-202718-1-.jpg)

![20151110_180222[1].jpg 20151110_180222[1].jpg](https://cdn.homebrewtalk.com/data/attach/268/268158-20151110-180222-1-.jpg)

![20151110_180324[1].jpg 20151110_180324[1].jpg](https://cdn.homebrewtalk.com/data/attach/268/268159-20151110-180324-1-.jpg)

![20151110_184109[1].jpg 20151110_184109[1].jpg](https://cdn.homebrewtalk.com/data/attach/268/268160-20151110-184109-1-.jpg)

![20151110_184126[1].jpg 20151110_184126[1].jpg](https://cdn.homebrewtalk.com/data/attach/268/268161-20151110-184126-1-.jpg)

![20151110_202718[1].jpg 20151110_202718[1].jpg](https://cdn.homebrewtalk.com/data/attach/268/268162-20151110-202718-1-.jpg)

NickTheGreat

Well-Known Member

- Joined

- Apr 17, 2012

- Messages

- 1,291

- Reaction score

- 531

Wow what an update! And congrats on the upcoming "assistant."

Trust me, brew now, while you have the chance. You won't have time, at least in the first 6 months!

Trust me, brew now, while you have the chance. You won't have time, at least in the first 6 months!

Similar threads

- Replies

- 0

- Views

- 344

- Replies

- 3

- Views

- 956

- Replies

- 15

- Views

- 1K

![20151107_160901[1].jpg 20151107_160901[1].jpg](https://cdn.homebrewtalk.com/data/attach/267/267568-20151107-160901-1-.jpg)