DSmith

Well-Known Member

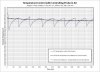

The controller is monitoring the carboy wall temperature under a lot of insulation. The 65F cut-out is my set-point (cut-out at setpoint). The cold air in the freezer + thermal mass of the freezer after it's powered off do not seem to decrease the carboy temperature any further.

I understand what you're doing with the probe in the air. I do the same thing for heating mode and the carboy temperature is VERY stable. I generally try to end all my fermentation in heating mode or just the basement temperature. I rigged a switch to transition between modes - pic below.

I like that the probe on the carboy approach is very hands-off; have been on work-trips when all this is happening. The probe in the air during active fermentation will need some set-point intervention and intuition. The Love TSS2 with a single probe looks like a better controller than the Johnson because it's the only one that can do differentials to 0.1F increments, heating & cooling is a big plus. I could attempt a fermenation your way and log it.

I understand what you're doing with the probe in the air. I do the same thing for heating mode and the carboy temperature is VERY stable. I generally try to end all my fermentation in heating mode or just the basement temperature. I rigged a switch to transition between modes - pic below.

I like that the probe on the carboy approach is very hands-off; have been on work-trips when all this is happening. The probe in the air during active fermentation will need some set-point intervention and intuition. The Love TSS2 with a single probe looks like a better controller than the Johnson because it's the only one that can do differentials to 0.1F increments, heating & cooling is a big plus. I could attempt a fermenation your way and log it.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)