- Joined

- May 6, 2025

- Messages

- 286

- Reaction score

- 222

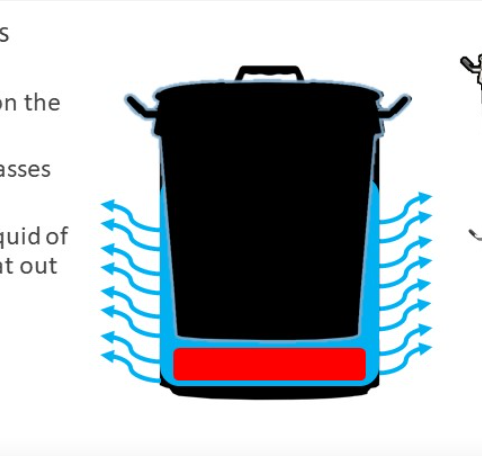

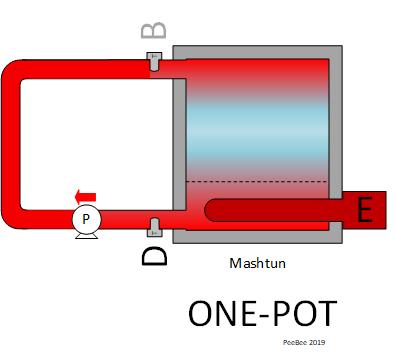

I have a Brewzilla So I have a solid wall mash pipe instead of a bag. And that means that the wort between the walls of the pipe and the outside of the machine, does not move around much. Can be called "dead space"

And it's a surprisingly large amount. Since it's on the outside, geometry evidently tells us that it's a lot of volume. Liters and liters of it.

But is this a problem? Some online say it is. Some AIO owners lift and lower the pipe. You have to be careful with that, with a Brewzilla as our bottom plate is loose and lowering too fast will upset it and pour out grains. But you can do it. And that would certainly mix up the waters nicely.

My last batch I followed some advice and directed the recirc hose into a lifting hole and did a brief recirc in the dead space that way. But that was also a hassle, as the wort just ran down one section and I had to keep rotating the pipe to get at all of it.

And tonight, after my second sip of whisky, I suddenly wondered if it's even a problem.

ok, so this strike water in between the walls is not actively involved with the grist. It's not doing the job of saccharification.

But in a full volume mash, who cares. I sometimes do a 6 liter pour over, instead of a full volume. That sparge water never did any saccharification work at all. And that's fine.

Seriously, is this dead inner wall space thing, actually a problem?

Thanks in advance for your input. Picture below, as we all like pictures

And it's a surprisingly large amount. Since it's on the outside, geometry evidently tells us that it's a lot of volume. Liters and liters of it.

But is this a problem? Some online say it is. Some AIO owners lift and lower the pipe. You have to be careful with that, with a Brewzilla as our bottom plate is loose and lowering too fast will upset it and pour out grains. But you can do it. And that would certainly mix up the waters nicely.

My last batch I followed some advice and directed the recirc hose into a lifting hole and did a brief recirc in the dead space that way. But that was also a hassle, as the wort just ran down one section and I had to keep rotating the pipe to get at all of it.

And tonight, after my second sip of whisky, I suddenly wondered if it's even a problem.

ok, so this strike water in between the walls is not actively involved with the grist. It's not doing the job of saccharification.

But in a full volume mash, who cares. I sometimes do a 6 liter pour over, instead of a full volume. That sparge water never did any saccharification work at all. And that's fine.

Seriously, is this dead inner wall space thing, actually a problem?

Thanks in advance for your input. Picture below, as we all like pictures

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)