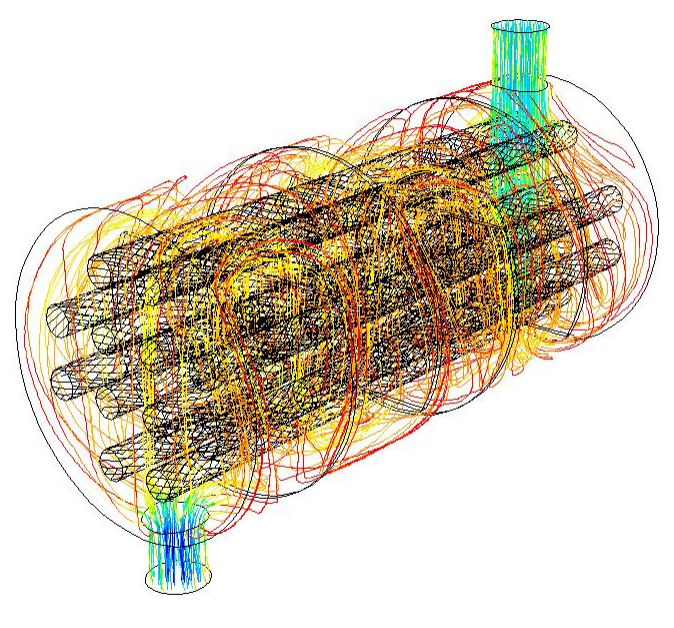

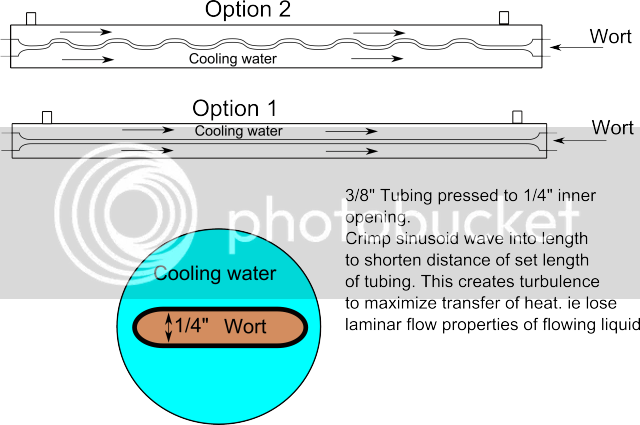

I think the whole point to the OP is to maximize efficiency of a CFC. Sure you get your wort down to ground water temp when it comes out of the regular CFC, but how can we do the same thing using the less material & water? That's what efficiency is.

If we really wanted to we could build a whole elaborate refridgeration system that will get the wort to 70* in no time. It wouldn't be more cost efficient then a regular CFC though.

If we really wanted to we could build a whole elaborate refridgeration system that will get the wort to 70* in no time. It wouldn't be more cost efficient then a regular CFC though.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)