CodeRage

Death by Magumba!

So I built a CFC and really liked the results. I needed it to take up less space and really wanted to get rid of the fountain pump and extra bucket I was using. Maintaining an efficient use of space was also important.

So I wrapped the CFC around the MLT and plumbed the cooling jacket into the MLT's plumbing and will use the MLT as a the cold water storage. This succeeded in deleting the bucket and pump.

The waste water was going into the MLT so to keep from adding another bucket I would have to recycle the waste water some how. When I had a sparge ring I was very surprised at the amount of heat loss to the atmosphere as the mash recirculated. With some garden sprayers I found the other week I designed a misting contraption on the return side of the waste water. I am hoping a fair amount of heat will be lost before it returns to the ice bath in the HLT.

I am a little worried about the restriction caused by the little sprinkler heads slowing down the cooling flow too much. In an hour or so I will have some test results on the systems performance. So I've got my fingers crossed.

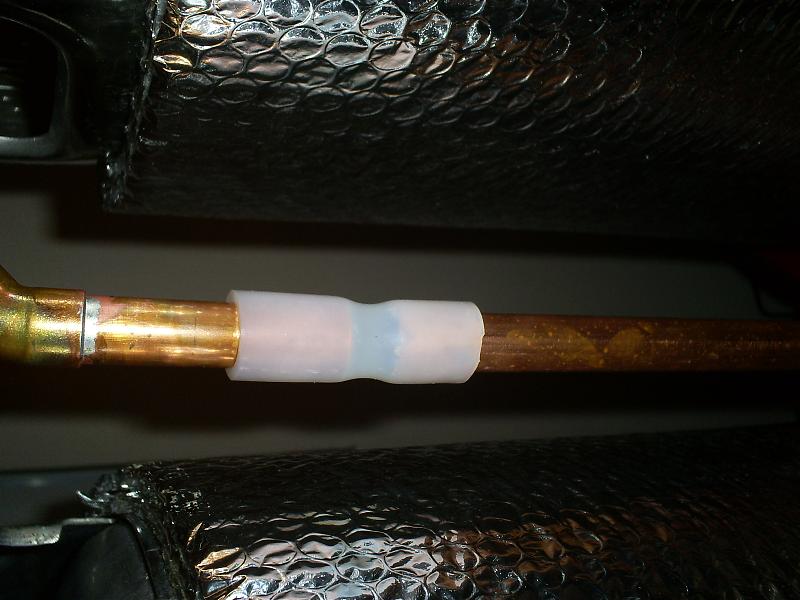

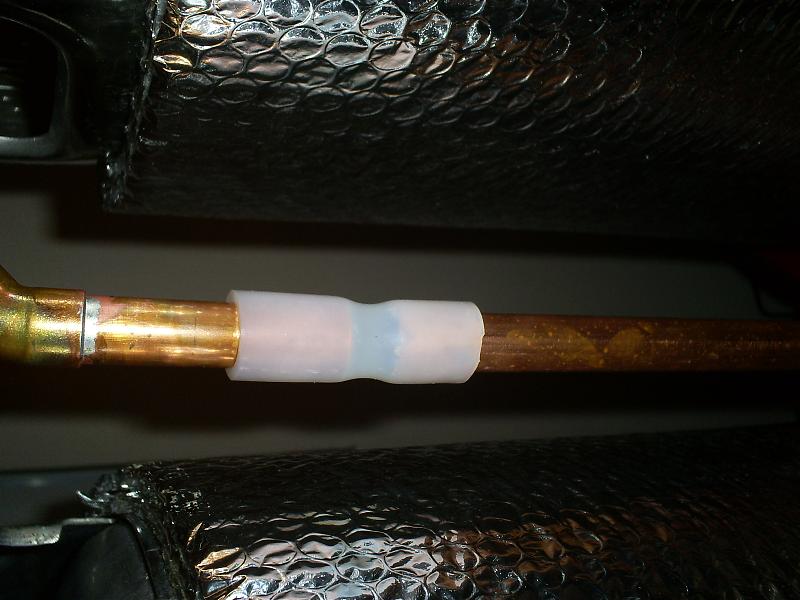

Also, I've mentioned using silicone tubing to splice to pieces of 1/2" pipe together. I've attached a photo of one I am using in action as a temporary union.

So I wrapped the CFC around the MLT and plumbed the cooling jacket into the MLT's plumbing and will use the MLT as a the cold water storage. This succeeded in deleting the bucket and pump.

The waste water was going into the MLT so to keep from adding another bucket I would have to recycle the waste water some how. When I had a sparge ring I was very surprised at the amount of heat loss to the atmosphere as the mash recirculated. With some garden sprayers I found the other week I designed a misting contraption on the return side of the waste water. I am hoping a fair amount of heat will be lost before it returns to the ice bath in the HLT.

I am a little worried about the restriction caused by the little sprinkler heads slowing down the cooling flow too much. In an hour or so I will have some test results on the systems performance. So I've got my fingers crossed.

Also, I've mentioned using silicone tubing to splice to pieces of 1/2" pipe together. I've attached a photo of one I am using in action as a temporary union.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)