6/5/2016 update

after a several week wait, menards finally had one of their 11% off sales. ran there in the morning to grab the parts for my keg/carboy cleaner build. starting with parts:

turns out menards also sells gama lids so i grabbed some of those and some food-grade buckets for grain storage. start with the pump:

the pump includes a float switch with receptacle on the end for plugging in the pump itself. switch floats to the top of the sump, closes the internal switch and starts the pump. but the pump can also be plugged directly into a wall receptacle or extension cord (always on function). i don't need the float so i took it off (s simply clamp which held the float cord to the pump housing:

rough idea of what the assembled components will look like:

pump discharge goes into a cross-fitting. the left and right branches are for keg disconnects, to clean posts and dip tubes while the main cavity is being cleaned (there will be hose between the barb fitting on the tee and the disconnect). the 'top' of the tee discharges out the top of a pip into the carboy/keg. the whole assembly (aside from the gray pipe) will be inside the bucket.

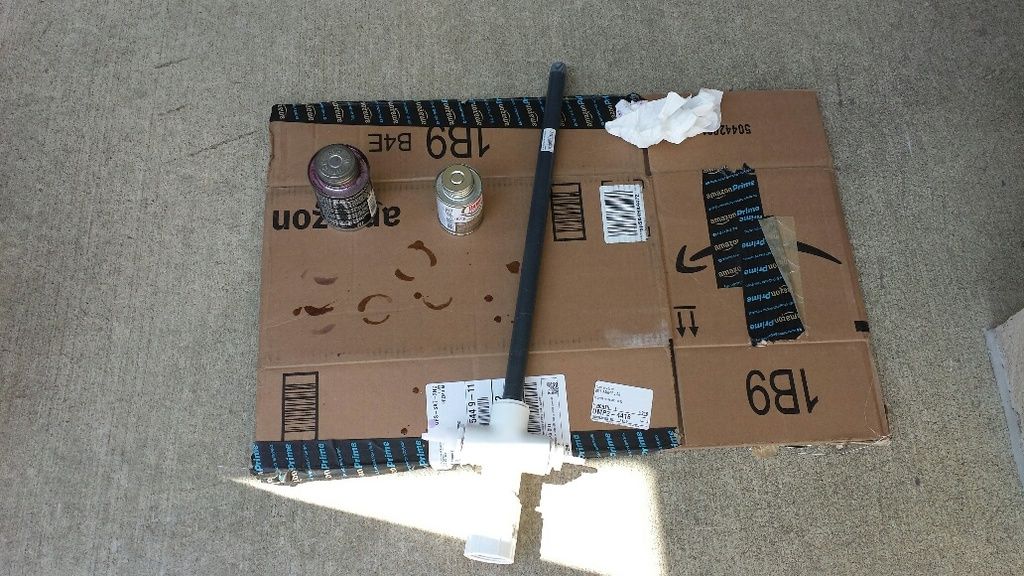

discharge of the pump is 1-1/4" male threaded discharge. so left-to-right in the above photo is a 1-1/4" female adapter, 1-1/4" to 1" reducing bushing, short length of 1" piping and 1" cross-fitting. gluing parts and pieces outside, with some cardboard to catch any primer/glue drips:

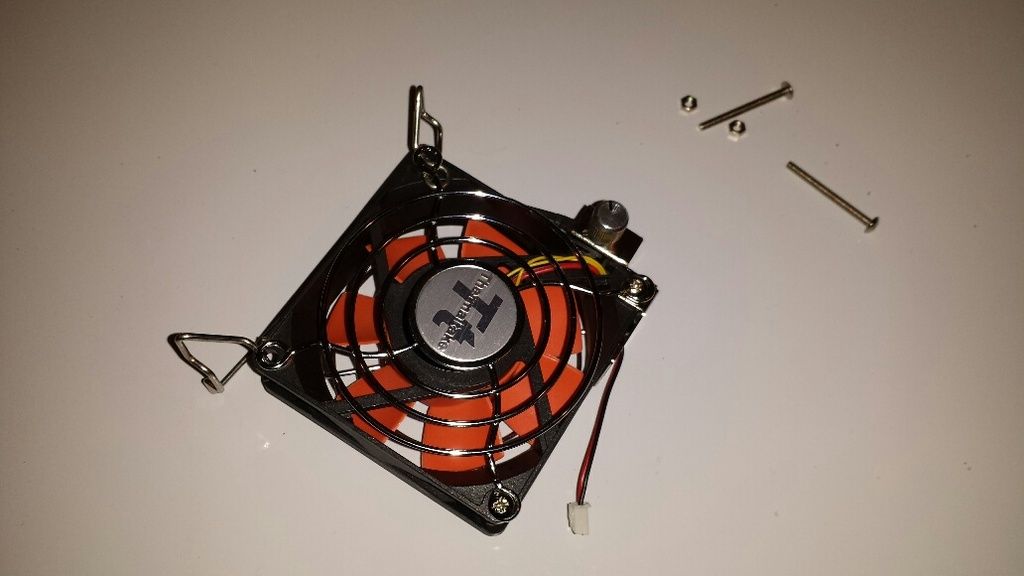

and all glued up. the side connections are 1" glued to 1/2" female threaded adapters. then there are 1/2" male to 1/4" barb nylon fittings threaded in. the top discharge is another 1" glued to 1/2" female threaded adapter with an 18" long, 1/2" pvc-80 nipple:

lid marked for cutting:

mid-cut. some left-hand cutting shears made for nice, clean cuts:

and the final product:

holes cut for the keg connection tubing:

hole cut in the lid for the cord. assembly set in the bucket and lid attached:

hoses cut to length. note sure what the pressure of the pump would be so i got reinforced vinyl tubing. probably overkill but it is cheap:

tubing attached to pump assembly:

and disconnects attached:

lid on, ready to go:

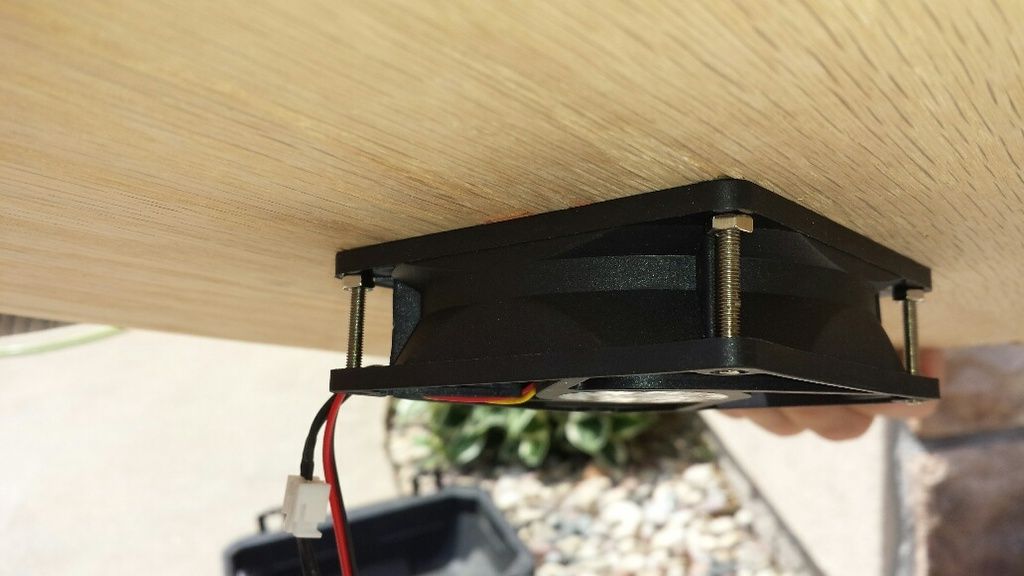

test fitting with the carboy stand. the 'feet' on the stand are at just a touch narrower diameter than the flat surface of the lid. it was a little wobbly so i stuck a couple 2x4s under it, much more stable:

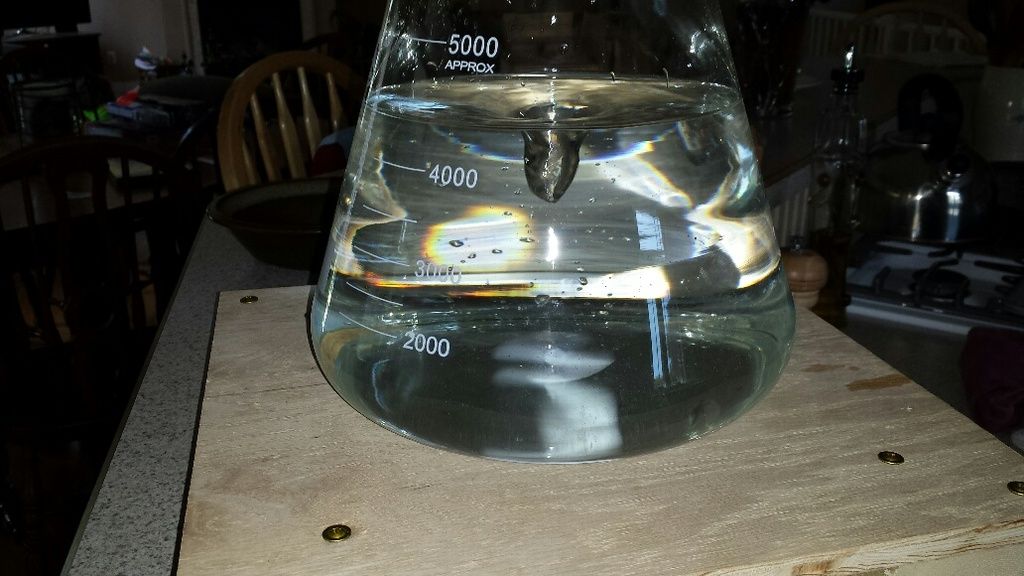

and with a carboy in place:

and the setup for kegs. that's a 3" to 4" clay pipe adapter. the 4" side fits nicely over the keg opening and the 3" portion nests down into the bucket. the keg is raised above the lid surface to allow for easier disconnect connections:

and with a keg in place:

time for a water test! first carboy test was a wreck. the carboy drying stand was 1.5" above the lid surface (because of the 2x4s) and water spilled everywhere as it drained out the bottom. so i put that clay pipe adapter in there but then the 2x4s were in the way (couldn't spread them far enough apart to accommodate the adapter and still have the 'feet' of the racks extend beyond the edge of the 2x4). solution was some 1x1s:

sort of a janky setup. the 1x1s allows for the clay pipe adapter to fit but they are not at all stable for the carboy drying rack when only supported on two sides. i'll need to trim those 1x1s down and make a square frame for the drying rack to rest on. flow is incredible, the entire inside surface is coated. glad i went with the 1/3 hp pump. setup with a keg:

with a functioning system, i spent the rest of the afternoon washing kegs. the kegs are new but they definetly have some manufacturing oils and similar inside of them. i mixed up two gallons of hot water with some pbw and washed each keg for 10 minutes. i washed four kegs before making fresh cleaning solution. sure enough, there was a noticeable sheen in the waste water, glad i washed them. then i set them up to dry:

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)