mrsducky

Member

- Joined

- Apr 25, 2017

- Messages

- 14

- Reaction score

- 1

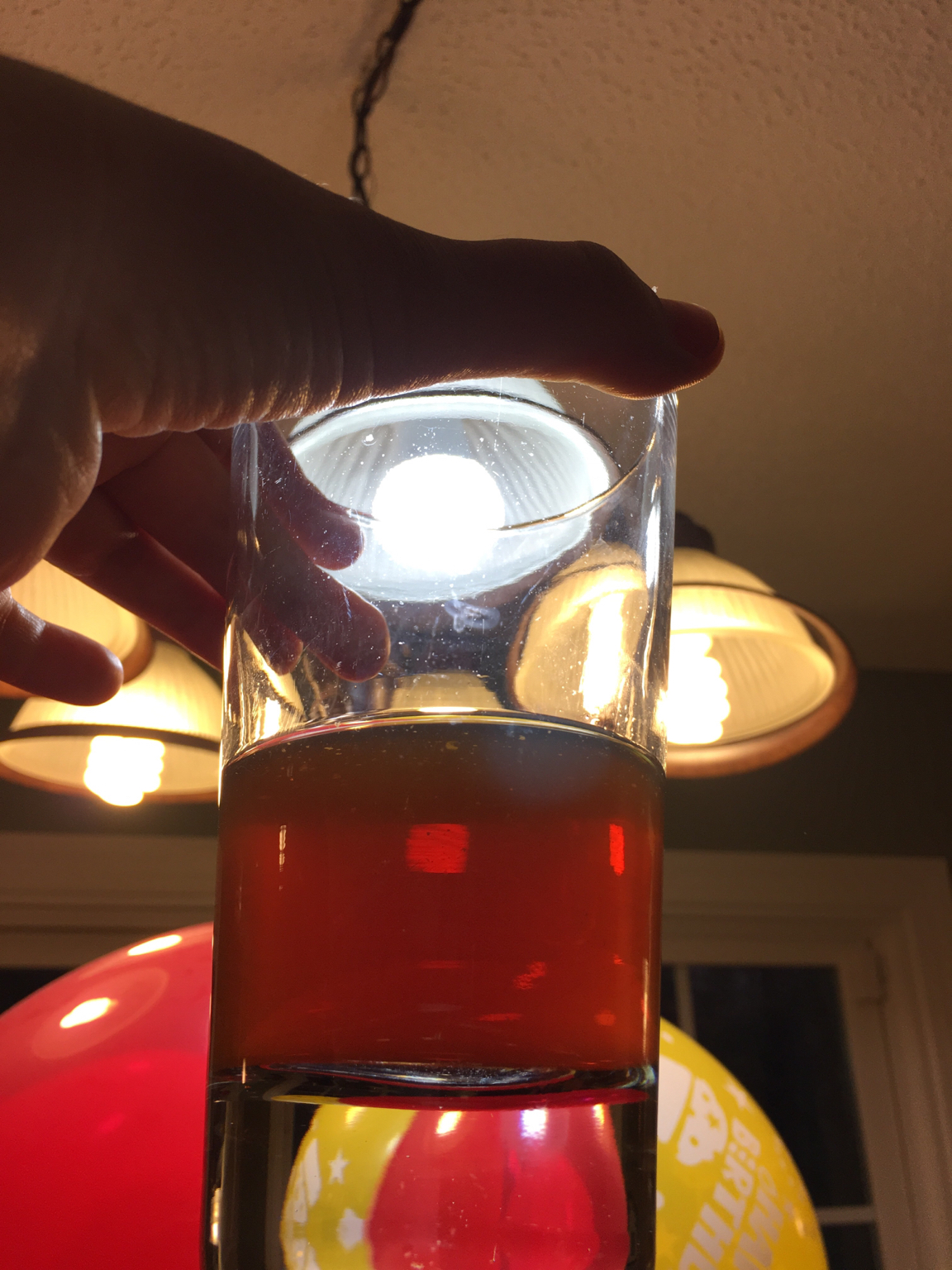

Here is the gunk I found in my bottles after they were done carbonating. I would have titled this “infection in secondary” because I saw what I’m fairly certain is the same hunk beginning there, but my bottles aren’t gushing like the typical description of an infected beer. In fact, one has no carbonation at all! So I am not sure what it is.

I’ve brewed a few beers / ciders before and none of them were infected, but these two had issues as well as the beer I brewed before these. The wort tasted great coming out of the fermenter but after the bottling step seemed to deteriorate. I wondered if it was my equipment, but I use the same tubes to bottle and transfer so I don’t understand why it would only seem to take hold on the second step?

More details —

2 beers I brewed for thanksgiving. First is a NB smashing pumpkin (added the pumpkin). Second was BIAB maple chocolate porter from Brooklyn brewshop. Both worts tasted very good and my efficiency was decent (don’t have notebook on me).

Both went through a primary for two weeks then secondary to help filter and clarify for three weeks. Cold crashed then bottled, for almost two weeks. Used carbonation drops (maybe that’s where the infection is being introduced?). Both tasted fantastic out of the fermenter.

When I opened the pumpkin there was absolutely no carbonation whatsoever. Just flat and very vinegary. Smelled somewhat off, not like a sewer but definitely not appetizing. Here is a picture of the gunk, which was somewhat present in the fermenter too.

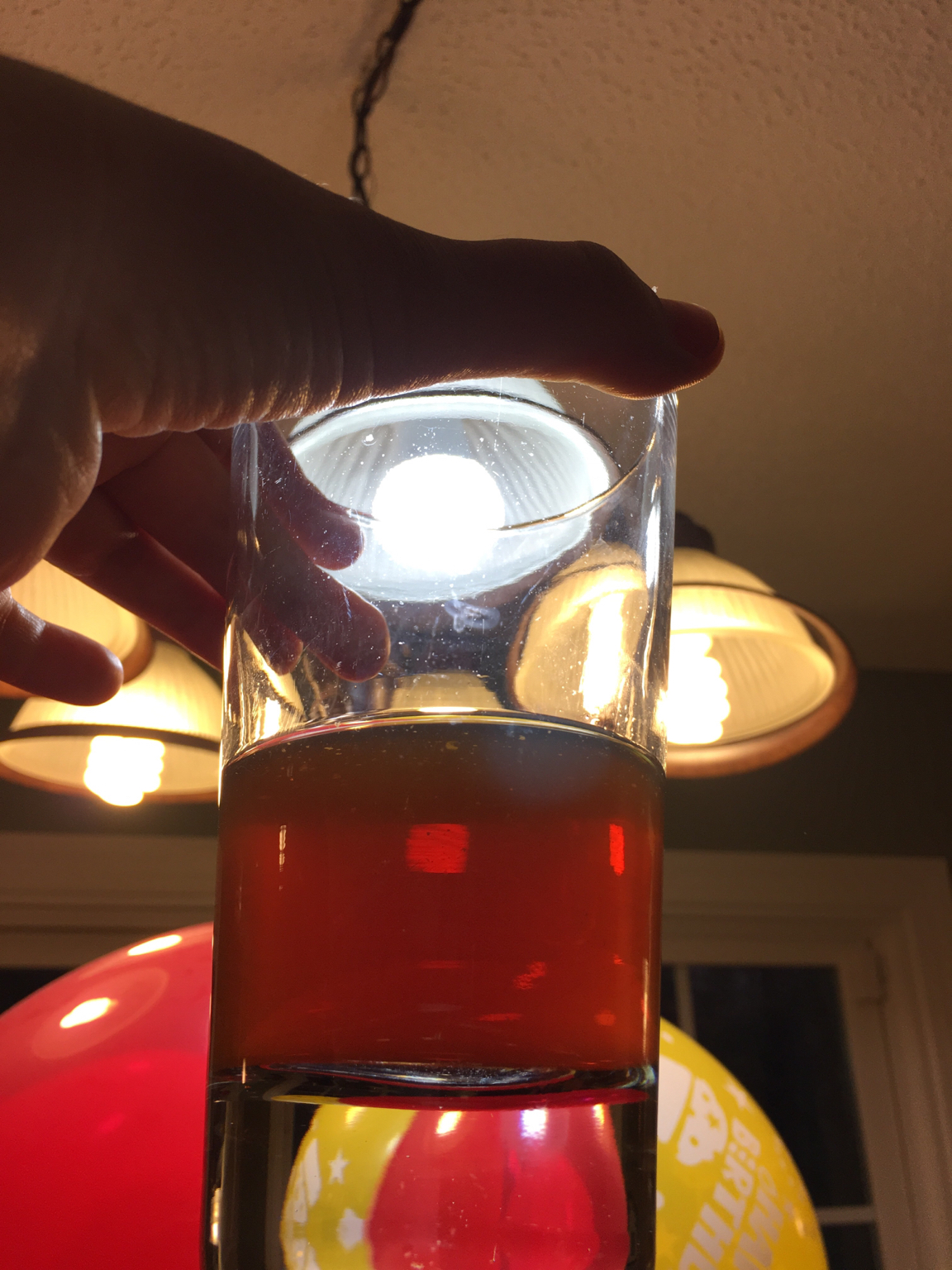

And the beer in general

The porter was carbonated quite nicely, not gushing either. However there was a somewhat drying aftertaste, maybe a little astringent. Tasted halfway decent but just something ... off. And not at all similar to the wort. Strange feeling on the tongue after, and an odd smell too.

My sister described the smell and taste like when the soda machine runs out of syrup and you taste the CO2.

Bottle crud:

Beer in glass

Another odd thing is that the porter had a few little goopy particles in the fermenter that were pill-shaped, which immediately made me think “bacteria” but it doesn’t seem to have affected the beer quite as much as whatever is in the pumpkin.

These are the fourth and fifth beers I have brewed. Beers 1 and 2 turned out well (in terms of infections - no issues) and beer 3 had a few semi-gushers and bottles that seemed infected and had a sour aftertaste. Again, wort tasted good but after bottling not anymore.

Where am I going wrong? How can I diagnose the issue without spending tons of money on all new equipment?

Or do I just need a keg

Happy thanksgiving!!!!!

I’ve brewed a few beers / ciders before and none of them were infected, but these two had issues as well as the beer I brewed before these. The wort tasted great coming out of the fermenter but after the bottling step seemed to deteriorate. I wondered if it was my equipment, but I use the same tubes to bottle and transfer so I don’t understand why it would only seem to take hold on the second step?

More details —

2 beers I brewed for thanksgiving. First is a NB smashing pumpkin (added the pumpkin). Second was BIAB maple chocolate porter from Brooklyn brewshop. Both worts tasted very good and my efficiency was decent (don’t have notebook on me).

Both went through a primary for two weeks then secondary to help filter and clarify for three weeks. Cold crashed then bottled, for almost two weeks. Used carbonation drops (maybe that’s where the infection is being introduced?). Both tasted fantastic out of the fermenter.

When I opened the pumpkin there was absolutely no carbonation whatsoever. Just flat and very vinegary. Smelled somewhat off, not like a sewer but definitely not appetizing. Here is a picture of the gunk, which was somewhat present in the fermenter too.

And the beer in general

The porter was carbonated quite nicely, not gushing either. However there was a somewhat drying aftertaste, maybe a little astringent. Tasted halfway decent but just something ... off. And not at all similar to the wort. Strange feeling on the tongue after, and an odd smell too.

My sister described the smell and taste like when the soda machine runs out of syrup and you taste the CO2.

Bottle crud:

Beer in glass

Another odd thing is that the porter had a few little goopy particles in the fermenter that were pill-shaped, which immediately made me think “bacteria” but it doesn’t seem to have affected the beer quite as much as whatever is in the pumpkin.

These are the fourth and fifth beers I have brewed. Beers 1 and 2 turned out well (in terms of infections - no issues) and beer 3 had a few semi-gushers and bottles that seemed infected and had a sour aftertaste. Again, wort tasted good but after bottling not anymore.

Where am I going wrong? How can I diagnose the issue without spending tons of money on all new equipment?

Or do I just need a keg

Happy thanksgiving!!!!!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)