kal

Well-Known Member

Cool! Then you're good to go!

Kal

Kal

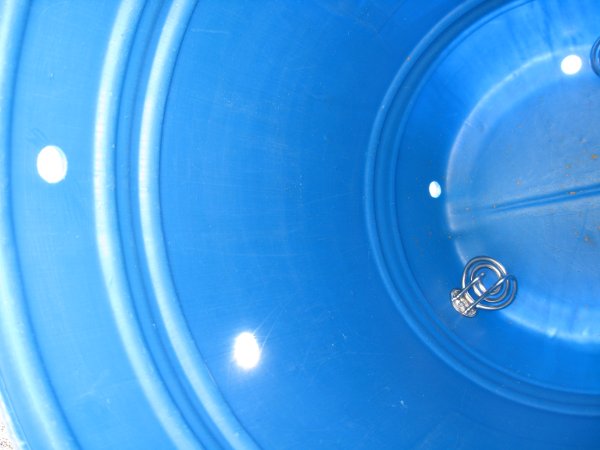

That's sweet man. I'm working om my 55 gal MLT and had the idea of wood boards around it. Now seeing yours I may do that. Looks great.

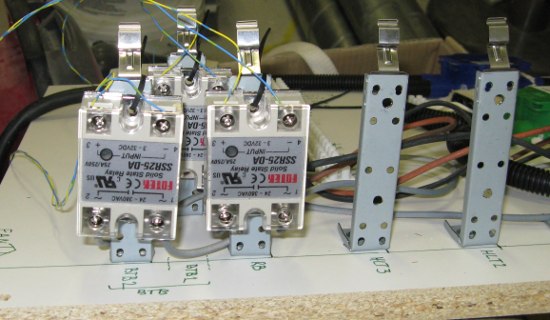

So you figure 20 kWh's? Thats not so bad then.

When do you think you will be able to brew your first beer on this system?

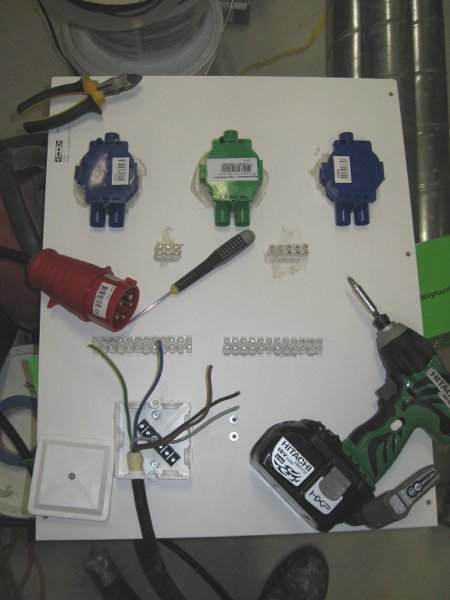

Well I think that I will be able to brew some first brews on the system within 2 weeks (unless I have to work a lot overtime).

But brewing with the system when it's "done"...wonder if that will ever happen, guess I can find things to improve forever

Can you control fluid flow with that pump?

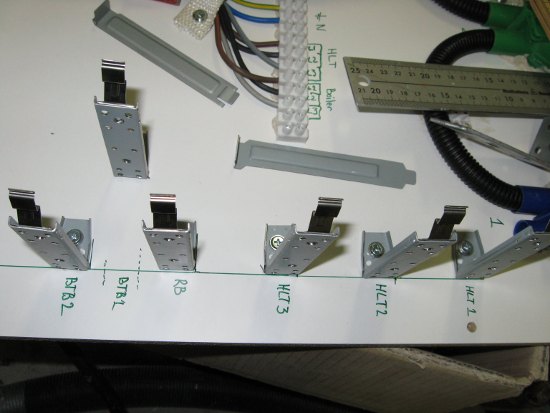

2. Do speed regulation with a dimmer (but then it needs to be a special type of dimmer that can manipulate the frequency don't know the name for that type of dimmer)

Great work , I am watching and enjoying this build !

Thank you.

Glad that people are enjoying the build, I really enjoy working with it so I hope that folks don't get bored with all my postings.

It's great to see the progress...keep 'em comin'!!