I'm doing some experimentation with using fermenter-produced CO2 to purge kegs and because the tubing I'm using (EVAbarrier 5mm ID) is so skinny there's the existential thread of krausen plugging it up and causing perhaps exciting results. There are two carboys chugging away, and I do have a solution that will mitigate krausen issues if needed - wide bore blowoffs leading to a 1/2 gallon PET bottle that has a outlet port for the thin tubing, but I'd prefer not to use it yet.

So, I have an esp32-cam trained on the exhaust bottle at the very end of the line, and I just stuck another one in the ferm chamber. Which, of course, gets very dark when the door is closed, so what to do?

BrewPi is the answer!

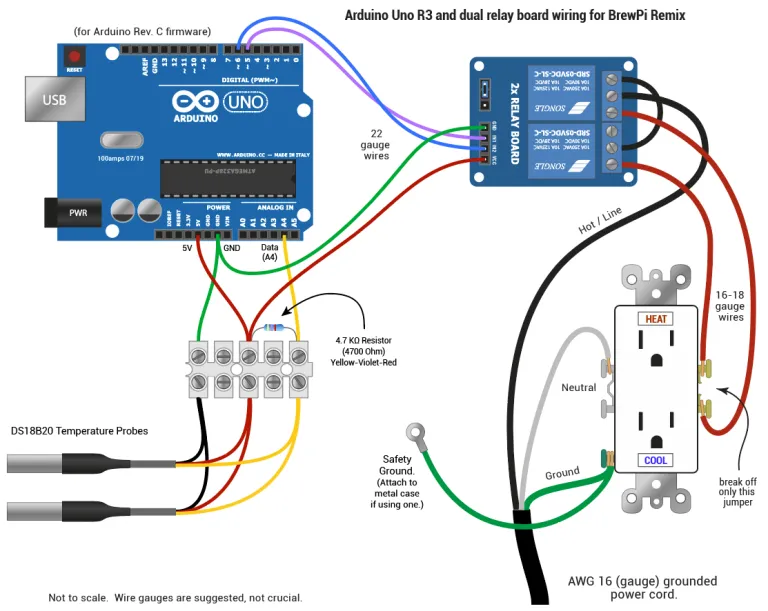

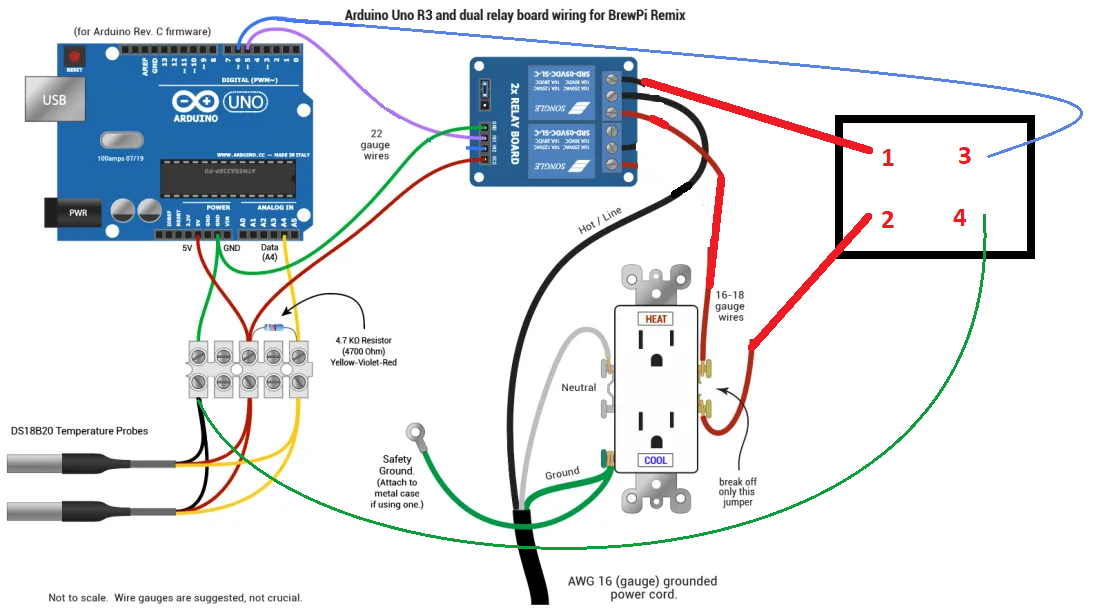

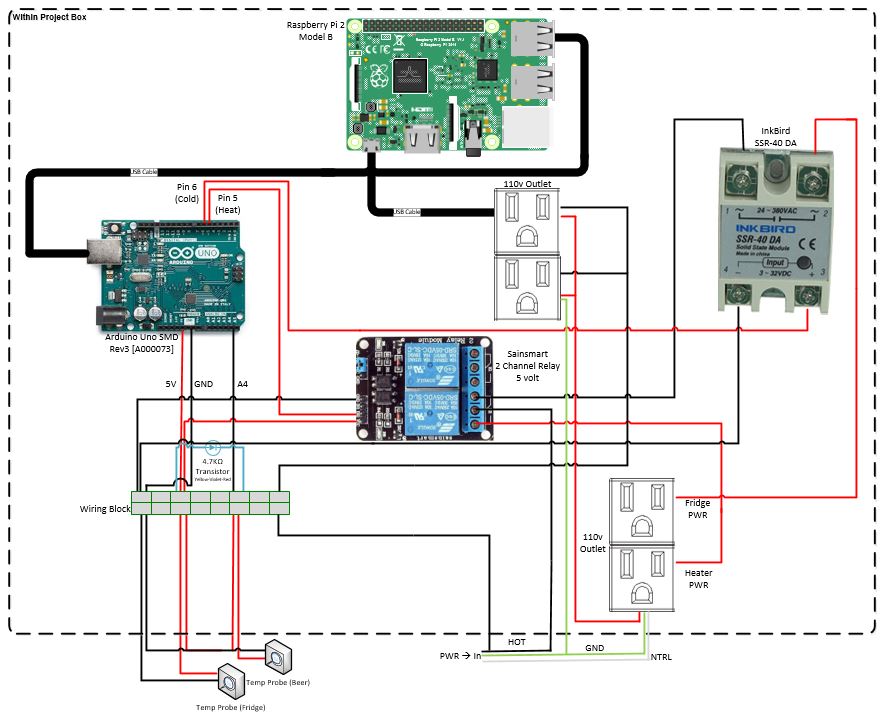

I disconnected my chamber heater ('cuz I sure as heck won't need it for awhile), plugged in a small lamp that I could perch on a door shelf - next to the esp cam - then changed the

BrewPi setting for GPIO6 from

Chamber Heater to

Chamber Light. Et voila! By toggling the Pin type setting between Inverted/Non-inverted I can turn the light on and off remotely!

View attachment 687521

Now I can periodically turn on the light and check the carboys. If that krausen gets close to the neck it'll be time to implement Plan B.

btw, no issues having the esp32 inside the fridge, even though its access point is a room away...

Cheers! (

BrewPi! Is there anything it can't do?

)

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)