You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

HOWTO - Make a BrewPi Fermentation Controller For Cheap

- Thread starter FuzzeWuzze

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

- Status

- Not open for further replies.

wbarber69

Well-Known Member

- Joined

- Oct 13, 2013

- Messages

- 2,191

- Reaction score

- 263

Question. Are any of using a 4 or 8 relay board? And if you are have you been able to switch different relays on the same board from multiple arduinos. I say that because it's like $1.50 difference between the 4 and the 8. And with 1 ssr and an 8 channel board I could control 4 chambers heating and cooling. But only if I can use 4 arduinos.

I bet as soon as I finish this project they'll release the next version of brewpi that let's me do all of this with 1 arduino.

I bet as soon as I finish this project they'll release the next version of brewpi that let's me do all of this with 1 arduino.

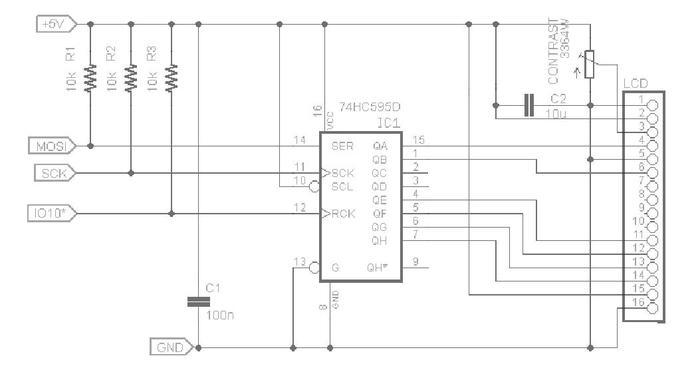

Here's the schematic that I've used.What's the part numbers for the new parts you added to the schematic. Also can you post the pinout of your shift register.

I appreciate you helping. I have tried to get my lcd up and running a few times now. But all I get is an lcd that lights up with the 1st and 3rd lines with solid blocks.

The history on github strongly suggests the AVR code barely fits as it is, so I think you'll be safe that single-Arduino/multi-chamber support isn't going to happen.

As for the relay module, I've been using Sainsmart 2 channel 5V modules, but they have an 8 channel 5V module with 8 discrete digital inputs. As long as there is a common ground between the Arduinos and that relay module you could literally have eight Arduinos controlling one relay each...

Cheers!

As for the relay module, I've been using Sainsmart 2 channel 5V modules, but they have an 8 channel 5V module with 8 discrete digital inputs. As long as there is a common ground between the Arduinos and that relay module you could literally have eight Arduinos controlling one relay each...

Cheers!

wbarber69

Well-Known Member

- Joined

- Oct 13, 2013

- Messages

- 2,191

- Reaction score

- 263

$76.92 ($2,179.04 / Ounce)

Brewing accessories 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304 Brewing accessories(Gas Hose Barb)

chuhanhandianzishangwu

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$479.00

$559.00

EdgeStar KC1000SS Craft Brew Kegerator for 1/6 Barrel and Cornelius Kegs

Amazon.com

$49.95 ($0.08 / Fl Oz)

$52.99 ($0.08 / Fl Oz)

Brewer's Best - 1073 - Home Brew Beer Ingredient Kit (5 gallon), (Blueberry Honey Ale) Golden

Amazon.com

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

They still drop 0.3 to 0.7 volts across them depending on if they're silicon or germanium, etc.

FWIW - This is what I'm using on my BrewPi - http://www.ebay.com/itm/5V-Two-2-Ch...345?pt=LH_DefaultDomain_0&hash=item2a26055221

But I'm only trying to control one chamber too.

+1

I use these. Cheap as chips and work like a charm.

wbarber69

Well-Known Member

- Joined

- Oct 13, 2013

- Messages

- 2,191

- Reaction score

- 263

You do realize that mechanical relays can cause arcing which can cause your compressor motor to throw sparks internally reducing the life of your fridge and possibly start a fire. It's not such a problem with the smaller dorm style refrigerators since they don't need a starting capacitor. But on larger chest freezers and stand up refrigerators it's something to worry about.

I bet nearly 100% of fridges and freezers have at least one set of switched points in front of the compressor...

Cheers!

Cheers!

wbarber69

Well-Known Member

- Joined

- Oct 13, 2013

- Messages

- 2,191

- Reaction score

- 263

I bet your wrong. I'm working with a 20 year old kenmore stand up that has a starting capacitor controlled by a non-0 crossing timer relay. And the compressor still makes this loud crunching sound when when it starts up.

FuzzeWuzze

I Love DIY

People have been using stc1000 and other controllers for years with no issue. Yes I'm sure it can happen but you likely have other issues like your fridges construction that will cause it to fail early.

wbarber69

Well-Known Member

- Joined

- Oct 13, 2013

- Messages

- 2,191

- Reaction score

- 263

The difference is I'm using a very old fridge that I would like to get at least a few more years out of. And those little 10-15amp relays don't really have the nuts to handle the start up of this motor. I can get by like I am now by tripping the thermostat side of the timer relay. But I want to alleviate all the extra nonsense and do it right. Larger refrigerators and freezers should, theoretically, not be controlled by contacting relays. But most of them have some kind of safety relay in line somewhere making it ok y to use the stc-1000 as long as you put it in place before the startup relay

FuzzeWuzze

I Love DIY

I think your over engineering a problem that doesn't really exist, but you have a weird setup and i cant stop you so good luck

I bet your wrong. I'm working with a 20 year old kenmore stand up that has a starting capacitor controlled by a non-0 crossing timer relay. And the compressor still makes this loud crunching sound when when it starts up.

Ok, I'll play: this magical relay has no points?

Cheers!

all_about_stouts

Well-Known Member

- Joined

- Dec 29, 2013

- Messages

- 71

- Reaction score

- 2

I'm about ready to give up.

I removed my linux partitions and reinstalled Ubuntu, which worked better than Debian the last time I tried.

I installed brewpi and everything looked ok. When I opened up the web page, I get 404 Not Found. I tried reinstalling brewpi and removing it and reinstalling, but nothing works. I'm not sure what I did wrong.

I removed my linux partitions and reinstalled Ubuntu, which worked better than Debian the last time I tried.

I installed brewpi and everything looked ok. When I opened up the web page, I get 404 Not Found. I tried reinstalling brewpi and removing it and reinstalling, but nothing works. I'm not sure what I did wrong.

MongooseMan

Well-Known Member

I'm about ready to give up.

I removed my linux partitions and reinstalled Ubuntu, which worked better than Debian the last time I tried.

I installed brewpi and everything looked ok. When I opened up the web page, I get 404 Not Found. I tried reinstalling brewpi and removing it and reinstalling, but nothing works. I'm not sure what I did wrong.

Just a note, the web code for the brewpi in Ubuntu needs to go in /var/www/html, not just /var/www.

Caught me out on my machine...

wbarber69

Well-Known Member

- Joined

- Oct 13, 2013

- Messages

- 2,191

- Reaction score

- 263

Do you understand what non-0 crossing relay is basically it's never really off. So it doesn't arc when it makes contact.

Sorry, the non-0 crossing thing didn't register.

Solid state, no points, sounds great. None of my coolers have one. Is that what turns on the juice to the compressor in response to a call for "cold" from the thermostat?

Cheers!

wbarber69

Well-Known Member

- Joined

- Oct 13, 2013

- Messages

- 2,191

- Reaction score

- 263

alphaomega

Well-Known Member

- Joined

- Jul 10, 2013

- Messages

- 1,041

- Reaction score

- 461

Arcing is a problem causing early malfunction of the relay, not the motor as far as I know.

Safety relay in series that makes it ok to use relay? Please elaborate

SSR's usually have zero crossing detectors (i.e. they are not non-zero crossing or random turn on).

Safety relay in series that makes it ok to use relay? Please elaborate

SSR's usually have zero crossing detectors (i.e. they are not non-zero crossing or random turn on).

By safety relay I mean the timer that keeps the fridge from coming on right away. Some have it some don't.

If the timer that enables the "safety relay" has elapsed before the thermostat calls for "cold", what does the controlling element look like then? Another SCR up stream? Bulb and capillary controlled switch?

Cheers!

alphaomega

Well-Known Member

- Joined

- Jul 10, 2013

- Messages

- 1,041

- Reaction score

- 461

Sure, it would make sense to put in a timer to prevent short cycling, but that has nothing to do with zero-crossing detection. I bet a relay will works just fine as long as it is rated to manange the startup current.

wbarber69

Well-Known Member

- Joined

- Oct 13, 2013

- Messages

- 2,191

- Reaction score

- 263

The schematic shows a non-0 crossing relay in the timer housing. The thermostat trips that I replaced the thermostat. I'm only doing all of this because elco made the recommendation. I argued everything you guys are saying. He even noted that these relay boards we are all using have their contact leads too close together to trust with high voltage. I said that the stc 1000 was basically the same. He told me I was on my own. Which is why I post exclusively to this forum now.

alphaomega

Well-Known Member

- Joined

- Jul 10, 2013

- Messages

- 1,041

- Reaction score

- 461

Well, a non-zero crossing relay is like a normal mechanical relay (not like an SSR).

And he is probably correct about the spacing on the relay boards. The stc does however have cuts in the pcb to have proper clearance.

And he is probably correct about the spacing on the relay boards. The stc does however have cuts in the pcb to have proper clearance.

alphaomega

Well-Known Member

- Joined

- Jul 10, 2013

- Messages

- 1,041

- Reaction score

- 461

[Double]

Well, a non-zero crossing relay is like a normal mechanical relay (not like an SSR).[...]

From what I've read it appears they're exactly like an SSR, with the addition of the detector. How could a mechanical relay close at exactly the instant that current isn't flowing in a 60hz line?

Wait - now I'm confused. Are we talking about a zero-crossing control or a non-zero-crossing control?

Cheers!

alphaomega

Well-Known Member

- Joined

- Jul 10, 2013

- Messages

- 1,041

- Reaction score

- 461

This is what I've been trying say all along...

A non-zero crossover detecting relay, does not detect zero crossovers, and will switch at any time, like a normal mechanical relay.

A zero crossover detecting relay, will have circuitry (diac/triac) to only allow switch on/off at zero voltage crossover (like most common SSR's).

A non-zero crossover detecting relay, does not detect zero crossovers, and will switch at any time, like a normal mechanical relay.

A zero crossover detecting relay, will have circuitry (diac/triac) to only allow switch on/off at zero voltage crossover (like most common SSR's).

alphaomega

Well-Known Member

- Joined

- Jul 10, 2013

- Messages

- 1,041

- Reaction score

- 461

Yeah, the little squiggly line would represent the coil of the relay.

But, the point is, a relay will be fine to control the compressor directly, even without the delay timer. As long as it is rated to withstand the startup current.

Arcing is an issue of the relay, but with a correctly rated relay, should not be an issue. It will not cause a fire or send sparks through your compressor.

In fact, a relay might be a better choice than SSR in this application, as inductive loads can be problematic for SSR's.

But, yes the cheap relay modules for arduino, while the relays might be rated correctly, the PCB design may be bad, lacking proper clearance on the high voltage side. A lot of cheap electronics from china has this problem (cheap chargers etc).

But, the point is, a relay will be fine to control the compressor directly, even without the delay timer. As long as it is rated to withstand the startup current.

Arcing is an issue of the relay, but with a correctly rated relay, should not be an issue. It will not cause a fire or send sparks through your compressor.

In fact, a relay might be a better choice than SSR in this application, as inductive loads can be problematic for SSR's.

But, yes the cheap relay modules for arduino, while the relays might be rated correctly, the PCB design may be bad, lacking proper clearance on the high voltage side. A lot of cheap electronics from china has this problem (cheap chargers etc).

stewart194

Well-Known Member

So, I've been so busy at work for the past several weeks that I couldn't get motivated to brew for a long time, but I finally brewed my first batch using my BrewPi setup and everything is going great. Thanks again to everyone who helped me get it up and running.

Quick question. I use an immersion chiller to cool the wort, and usually it can cool it down to 70 no problem. But it's been crazy hot here lately, and since my temp sensors are really accurate now, this batch was 80 degrees when I pitched the yeast. My refrigerator took about 12 hours to get it down to 63 degrees.

Should I cool my carboys down to 63 in the fridge before pitching the yeast the next time? What do you guys do?

Thanks!

Quick question. I use an immersion chiller to cool the wort, and usually it can cool it down to 70 no problem. But it's been crazy hot here lately, and since my temp sensors are really accurate now, this batch was 80 degrees when I pitched the yeast. My refrigerator took about 12 hours to get it down to 63 degrees.

Should I cool my carboys down to 63 in the fridge before pitching the yeast the next time? What do you guys do?

Thanks!

My well runs around 50°F year 'round, so I don't really have much of a problem getting down to 65°F. But if I'm doing a double brew on these hot days if I didn't park the first batch in the fermentation fridge it'd drift back up into the 70s by the time I pitched both batches.

So I would get the wort down to ideal pitching temperature in any case. It's just one of those things to get right so your results are consistent...

Cheers!

So I would get the wort down to ideal pitching temperature in any case. It's just one of those things to get right so your results are consistent...

Cheers!

ejluttmann

Well-Known Member

During the summer, after I get the initial temperature down, I prechill the water to get it down that last bit. I use an old immersion chiller that I place in a bucket of ice to bring the water temp down.

Sent from my iPhone using Home Brew

Sent from my iPhone using Home Brew

wbarber69

Well-Known Member

- Joined

- Oct 13, 2013

- Messages

- 2,191

- Reaction score

- 263

There isn't enough surface area for it to matter. I sanitize my carboys with hot water and sanitizer up until it's time to use them. Then I dump out the hot sanitizer, and let the carboys air cool for like 3 minutes and they are cool to the touch. Long story short the temperature if the glass will not have that large an impact

wbarber69

Well-Known Member

- Joined

- Oct 13, 2013

- Messages

- 2,191

- Reaction score

- 263

During the summer, after I get the initial temperature down, I prechill the water to get it down that last bit. I use an old immersion chiller that I place in a bucket of ice to bring the water temp down.

Sent from my iPhone using Home Brew

I use my HERMS coil and HLT with ice and water to pre-chill my hose water in the summer. It keeps me from doing back to back batches. But it can get up to 100 degrees in the shade here with 100% humidity so I don't have a choice half the time.

wbarber69

Well-Known Member

- Joined

- Oct 13, 2013

- Messages

- 2,191

- Reaction score

- 263

Grabbed this deal today

even better with prime shipping!

http://www.amazon.com/dp/B00KTELP3I/?tag=skimlinks_replacement-20 via @amazon

Says 14 left

http://www.amazon.com/dp/B00KTELP3I/?tag=skimlinks_replacement-20 via @amazon

Says 14 left

Last edited by a moderator:

FuzzeWuzze

I Love DIY

So, I've been so busy at work for the past several weeks that I couldn't get motivated to brew for a long time, but I finally brewed my first batch using my BrewPi setup and everything is going great. Thanks again to everyone who helped me get it up and running.

Quick question. I use an immersion chiller to cool the wort, and usually it can cool it down to 70 no problem. But it's been crazy hot here lately, and since my temp sensors are really accurate now, this batch was 80 degrees when I pitched the yeast. My refrigerator took about 12 hours to get it down to 63 degrees.

Should I cool my carboys down to 63 in the fridge before pitching the yeast the next time? What do you guys do?

Thanks!

Set your PID Maximum in your Settings to like 25F. As long as you never set your beer below 25F you should be fine. This allows your fridge to chill faster in these situations, as by default i think its 10 or 15F. This controls how big the difference between your fridge and beer temp can ever be. So if your beer was 80, it would have only kept the fridge at 70F, when it got to 79 it would have dropped the fridge temp to 69 etc...but if you set PID Max to 25F it would have been at 80F and dropped your fridge to 55F..larger delta allows faster cooling.

You could even do 30F, just know that there was a bug that if your fridge temp ever got set to something that allowed the fridge to go to or below 0 then it would screw up and go to 80F. Hopefully that makes sense.

Basically just take the coldest temp your fridge can ever get, subtract like 5F to give some breathing room and use that as your PID max.

In the future your better off just leaving until its hit your target temp and then pitching, even if that means waiting 6-12 hours for it to get there. If you sanitized properly you'll be fine. There are many people who no chill and it takes 24-48 hours to chill down to pitching temps before they throw in their yeast and they have no problems.

- Status

- Not open for further replies.

Similar threads

- Replies

- 10

- Views

- 2K

- Replies

- 3

- Views

- 2K