r8rphan

Well-Known Member

So, with my prior system, I used the "brew target" program to calculate recipes, and it was pretty straight forward... For the mash, I just entered the amount of water that the cooler would hold with the lid on in the equipment profile, and went from there.. I could play with the qt's per pound (with 1.25 qt. per pound being ideal) t make everything fit in my not that big mash tun...

But now, I have a vessel that has water space under the false bottom/grain bag, and I'm not sure if I need to consider that as part of the strike water or what.....

My new system holds about 4 gallons of water under the grains, with a max capacity of 14 gallons (leaving one inch to the rim of the keggle, which I'd rather not cut it that close), meaning there is up to 10g available for the area where the grains will be..

Am I supposed to enter the total amount of liquid the whole vessel will hold or just the amount from the false bottom up or what? And how do I figure out how much water to heat up before adding grains so that I don't have to worry about running our of room (overflow) when I add the grains, yet still have enough to do the mash?

Also, how many pounds per gallon do the grains take up in as far as volume goes, so that I know how much water the keggle can hold with the grains in there?

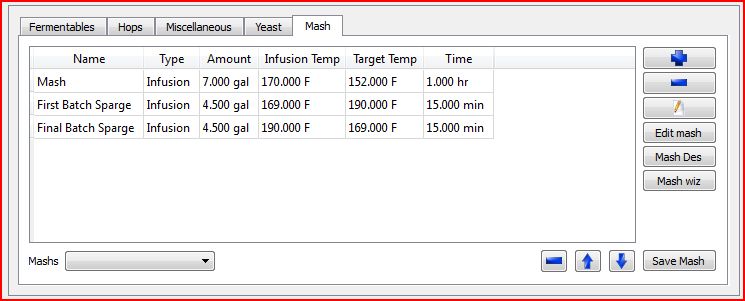

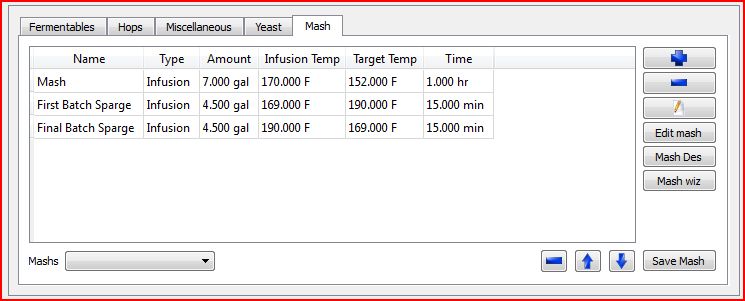

Here is a typical recipe and mash schedule with my old system, as well as a typical equipment profile for the same system...

But now, I have a vessel that has water space under the false bottom/grain bag, and I'm not sure if I need to consider that as part of the strike water or what.....

My new system holds about 4 gallons of water under the grains, with a max capacity of 14 gallons (leaving one inch to the rim of the keggle, which I'd rather not cut it that close), meaning there is up to 10g available for the area where the grains will be..

Am I supposed to enter the total amount of liquid the whole vessel will hold or just the amount from the false bottom up or what? And how do I figure out how much water to heat up before adding grains so that I don't have to worry about running our of room (overflow) when I add the grains, yet still have enough to do the mash?

Also, how many pounds per gallon do the grains take up in as far as volume goes, so that I know how much water the keggle can hold with the grains in there?

Here is a typical recipe and mash schedule with my old system, as well as a typical equipment profile for the same system...

:beard:

:beard: :rockin::fro::cross:

:rockin::fro::cross: