milldoggy

Well-Known Member

I fill my hlt, you need a mass of water after doughing in at target temp for the herms. I use a sight guage and have marked out each gallon with silicon orings.

Another hopstopper issue came up last night. I lost the siphon when the level dropped down to the nozel leaving about 1-2 gallons in the bottom. I thought I cranked that mo-fo on pretty tight, but I am wondering if a compression fitting is really the right design for something that is taken on and off with every brew day.

Have you tried taking the ferrules out and using a couple silicone o-rings? I did that with my compression fittings that require removal and re-installation, and I've had no problems. I think that's what Kal does too, if I'm not mistaken.

TB

Slow the flow right down once the hopstopper gets exposed to air, otherwise you can create a funnel which sucks in air.

Kal

Another hopstopper issue came up last night. I lost the siphon when the level dropped down to the nozel leaving about 1-2 gallons in the bottom. I thought I cranked that mo-fo on pretty tight, but I am wondering if a compression fitting is really the right design for something that is taken on and off with every brew day.

I don't really understand what you mean by the second part, but as for the first question: Keggles are 15 gallons and many keggle owners I know do 10 gallon batches.I need some opinions. Right now I have 3 15 gallon blichmanns. When I convert someday to Kal's electric brewery, I want to do 1o gallon batches still. Will i be able to pull it off with the 15 gallon system?

I am thinking about doing 10 gallons in the HLT and 10 gallons BK. Heat to strike water temp for both. Transfer bk water volume needed to mlt, and the remaining volume to hlt. Then continue using Kal's process.

With your technique for your system don't you heat up 20 gallons at once in the hlt and transfer what you need to the mlt? Then you use the water in the HLT to keep a constant temp in the mlt, then sparge?

Doing 10 gallon batches in 15 gallon pot would force me to use two pots to heat up sparge and strike water because I usually need 20 gallons of water for 10 gallon batches.

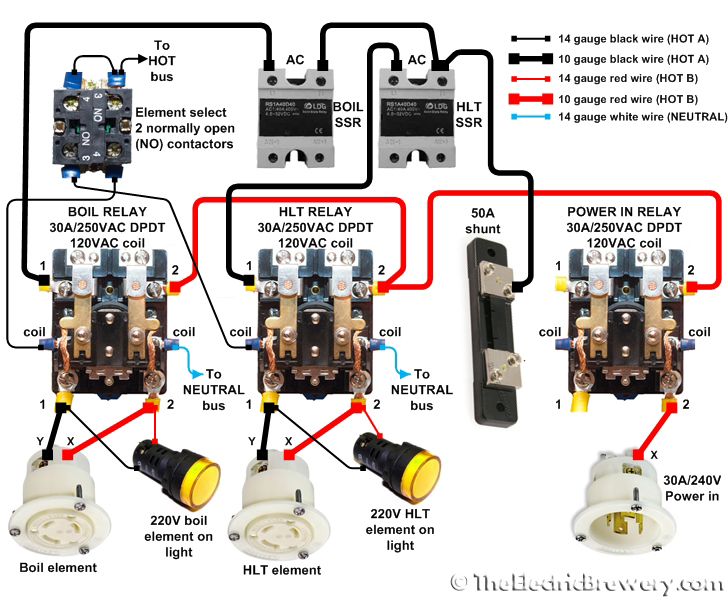

How about a wiring diagram? (Or if you posted it already - a link?)...

Can anyone offer some insight on whats going on. It's acting as if I have that 7 amp fuse on the element. I don't get it.

With your technique for your system don't you heat up 20 gallons at once in the hlt and transfer what you need to the mlt? Then you use the water in the HLT to keep a constant temp in the mlt, then sparge?

Doing 10 gallon batches in 15 gallon pot would force me to use two pots to heat up sparge and strike water because I usually need 20 gallons of water for 10 gallon batches.

Since the MLT on the electric brewery system does not have an electric element, I would be forced to heat up 20 gallons of water in the BK and the HLT.

So, I would need to heat up in strike water in the bk and transfer it to the mlt. At the same time I would need to heat up water for the sparge and for keeping the mash temp constant while recirculating.

You are absolutely right ... the mash tun size can limit the amount of beer made too if the gravity's high. This is why I went with 20 gallon kettles all around - it allows me to make 10 gallons of kegged product regardless of gravity. I tested this a year or so ago by making 10 gallons of 12% ABV barley wine. Had almost 40 lbs of grain in the mash tun - it was full to just a few inches from the top!I have 15 gallon commercial kettles (other than my 25 gallon BK) and I can probably do a 1.070 beer, max, before I have to get creative, at 80% efficiency. You guys are all talking water, but my constraint is the grain bed itself.

Actual temp. See the manual that came with the PID. Or don't do the auto-tune. It's not really needed. The PID will learn over time by itself.On another note, a question about the autotune process. When I go to do it, what should I set my target value to? Should it be 30-40 degrees above the actual temp or should be 2-3 degrees above the actual temp?

How did that barley wine come out? Barley wine is my absolute favorite type of beer

There appear to be very few changes. It's really just taking all of the 30A devices (and wiring) to 50A and adding one extra element in both the Boil Kettle and Hot Liquor tank.

For 1 barrel, I’d recommend two 5500W elements (not one) in both the Boil Kettle and Hot Liquor Tank. So 4 elements total. That's the major difference. That would give you the power and heating speed you’d need to boil vigorously and offer fast heat (ramp) times. I've never boiled 31+ gallons myself personally but from all I've read and the brewers I've talked to who have, 9000-11000W is what you want for 1 barrel (31 gallons).

Some say that two 4500W elements (9000W total) is enough but I'd suggest two 5500W elements (11000W total) for some added headroom and because the different in cost is negligible. The idea is to provide twice as much power to either kettle where only the boil kettle or hot liquor tank are enabled at once, similar to the current design. This does *not* allow the boil kettle and hot liquor tank to be run at the same time to shave off an hour or so during brew day when you want to brew back to back batches. That is not the intent here. You'll need to wait until the boil is over and you're chilling before starting the heat in the hot liquor tank for the second batch. True back to back batches where both kettles are energized would require twice the power again which would require 100A just for the brewery. That's a whole different realm of power requirements.

One thing to keep in mind is that the price of some of these things goes up considerably as soon as you go above 30A. Unless you *really* want to brew more than 20 gallons at once, stick with my 30 amp design.

The power side of the current 30A setup (controls one 5500W element at a time) looks like this:

Here's how to convert this to 50A to allow for 31+ gallon brews:

Not included are the 240V/50A stove outlet needed ont the wall that the power cord plugs in to. This outlet should be wired with 6 ga wire to the breaker panel and protected with a 60 amp dual pole GFI breaker. We use a 60A breaker (not 50A) so as to only load the circuit to 80%. Some may say that 50A would also be fine too.

- Replace the two 40A SSRs with 80A units. 11000W at 240V is 45.8 amps so the standard 40A one isn’t big enough. The next step up from 40A with SSRs is typically 80A.

- The 3 digit blue LED digital panel amp meter with 50A shunt with is large enough. No need for the next step up (usually a 100A shunt).

- Add two extra NEMA L6-30 (250VAC/30A) twist lock electrical female receptacles to the bottom of the enclosure for the two extra elements. The extra outlets would be wired in parallel (not series) with existing ones to give the same 240V drop across each element. Each receptacle would pull 5500W of power for a total of 11000W per kettle. I like the idea of just doubling up elements and keeping how they’re connected to the kettle and control panel exactly the same as it would be easier and also cheaper, you simply have two 10 ga cords going to each kettle instead of one. The other option is to upgrade the element receptacles and plugs to 50A versions and fatter 6 ga wire which goes into one outlet box on the kettle to power one element and then splits off with 10 ga wire (still wired in parallel) into a second outlet box to power the other element. This is likely messier, harder wiring, more connection points around the kettle. Also requires more of a redesign with different wiring of course, something that isn’t documented on my site. If we stick with what’s already documented it’s dead simple as people can just follow existing instructions. You just do 4 elements instead of 2.

- A bigger enclosure is needed instead of the 16x16x8 one due to the 2 extra element receptacles. There's no room left on the bottom. The 16x16x12 (deeper) one may be big enough, otherwise a 20x16x8 or 20x20x8 could be used.

- Replace the L14-30 (240V/30A) power input receptacle in the control panel with a 50 Amp, 125/250 Volt AC, Locking Grounded California-Style receptacle such as this one:

- The power cord for the control panel would be a standard 50A 4-conductor stove power cord such as this one:

.

It's a 4 conductor for 2 HOTS, 1 NEUTRAL, and GROUND, single phase. The two HOTs are 6 ga while the NEUTRAL and GROUND are slightly smaller 8 ga which is fine since they do not carry the brunt of the load. This cord has a NEMA 14-50R plug on the end. To the other end we need to attach a 50 Amp 125/250 Volt AC Locking Grounded California-Style connector such as this to connect to the control panel:

- Replace the three double pole 30A/250VAC relays with double pole 50A/250VAC contactors (you can't typically find relays this large).

- Replace all of the 10 ga T90/THWN/THHN wire in the control panel with larger 6 ga T90/THWN/THHN wire to allow for the larger current draw. There's actually not that much wire here. Only 8 feet of black (HOT1), 4 feet of red (HOT2), and 11 feet of GROUND. Some may argue that 8 ga for the GROUND would be fine too.

Nothing else changes from what I can see since the rest of the control panel is all 120V and straight forward. All the switches and how the panel operates would remain identical. You just now have twice as much power in each kettle, allowing easy brewing for up to 1 barrel of beer (31 gallons) and possibly more.

I'm not sure what the upper limit here is in terms of what 11000W of power can adequately boil as there's very little information available on the subject and I've never tried it myself. Given that some people are successfully brewing 1bbl with only 9000W, I'm thinking that 11000W should be adequate for up to possibly 1.5 bbl (?). If anyone has any experience with this let us know. That's a lot of beer.

Well, i figured out what all my problems were, made sure everything was reading the correct temps and i got from 58 degrees to 105 degrees in 35 minutes. I think thats pretty good for a 1500 watt element. My system is rims but ****, to save propane i may run the hlt water through the rims tube as well. Wake up in the morning, get it going and set the alarm. I can hear the alarm from anywhere in the house.

Great idea, Dave. I think I may try this next time as well. It would also help keep the element nice and clean over time.