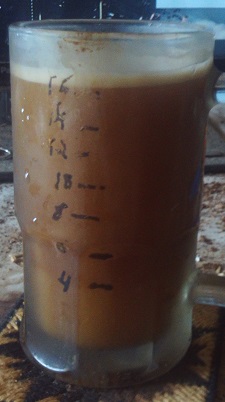

The beer is probably still somewhat undercarbed. The reason it's foaming is it's still warm and was shaken recently. Just give it time and you'll see. It's going to take time for the yeast to settle in any case.

i shook it around 4pm yesterday......(and i'm still not sure if my lines are long enough ~12' 1/4" lines...i think way back in 2006 i used a calc for 8psi for them.....)

my taprite reg says 8psi, but i think that could just be because it has a check valve.....

maybe after i got the 1.5oz of co2 into the kegs i should have rolled them a bit before putting them in the fridge......help distribute the co2 evenly.....

i'm also thinking it's significant it's really thick foam....almost like if i let it sit for a while it would fill the glass.....

(and lol! normally my fridge makes a hell of racket all the time, making think about getting a new one! now that i'm having fun and in a hurry to actually get my kegs cold, my kegs are still warm, and it's running quiet!

)

edit: another calc is telling me 27' for 1/4"? at 8 psi.....damn, i need to redo my lines.....were line length calcs different back in 2006? lol

now i'm thinking it is just properly carbed and my lines aren't long enough.....

i remember back then they had different resistances for different materials, and my vinyl was something like 2.7lb's a foot.....or .7 or something with a .7 involved....

i think stuff like this is where i got 12' from...

https://content.kegworks.com/blog/determine-right-pressure-for-your-draft-beer-system/

8psi/.65=12'

and i hooked up the keg that didn't take so much shaking on my other line, think i only gave it an ounce or so....perfect, except for the sediment.....(i didn't deculm this malt, so the beer is less then perfect....

)

)

)

)

)

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)